Reaction tower for preparing vinyl dichloro-alkane

A vinyl dichloroalkane and reaction tower technology, which is applied in the preparation of halogenated hydrocarbons, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of preparation work influence, inability to clean residues, solution residues, etc., to ensure stability , easy to clean, to ensure the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

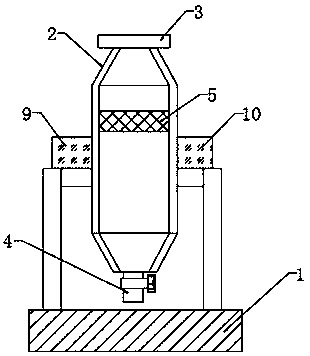

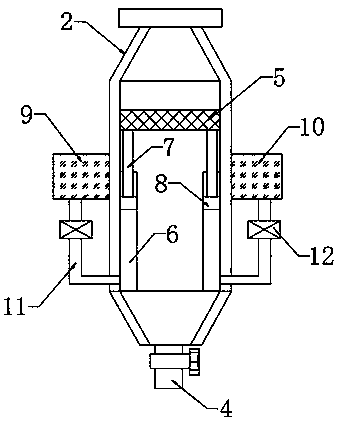

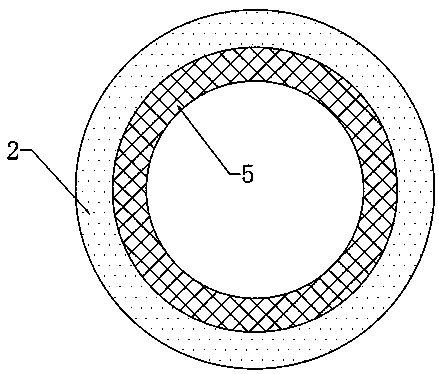

[0019] Such as Figure 1-3 As shown, the present invention provides a technical solution: a reaction tower for preparing vinyl dichloroalkanes, including a base 1 and a main body 2 installed above the base 1, and the base 1 and the main body 2 are installed by The upper end of the main body 2 is installed with a sealing cover 3, the lower end of the main body 2 is installed with a discharge pipe 4, the inside of the main body 2 is installed with a cleaning plate 5, and two sets of Lifting mechanism, the lifting mechanism is composed of a sleeve 6, a moving rod 7 and a counterweight 8, one end of the sleeve 6 is in contact with the inner wall of the main body 2, and the counterweight 8 is installed inside the sleeve 6 , the moving rod 7 is set through the sleeve 6, one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com