Preparation method of negative temperature coefficient thermistor material

A technology of negative temperature coefficient and thermistor, which is applied to resistors with negative temperature coefficient, resistors, non-adjustable metal resistors, etc., to achieve the effect of simple raw materials, stable adjustment performance and wide application temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Method example:

[0018] a. Take La2O3, MnCO3, CaCO3, ZrO2 as raw material, according to La2O3 is 22.5~47.5, CaCO3 is 5~55, Mn is 45~95, ZrO2 is 5~55 molar ratio after mixing, add water ball and grind into slurry, described The ball milling conditions are: material: ball: water ratio 1:3:3, ball milling time is 8 hours;

[0019] b. drying and calcining the slurry to obtain a solid powder material, the drying temperature is 250°C, the calcining temperature is 900-1200°C, and the time is 2-8 hours;

[0020] C. Add water to the solid powder material again and dry it after ball milling, and sinter to obtain the negative temperature coefficient thermistor material after pressing and molding. The ball milling condition is: material: ball: water is 1:3:3, and the ball milling time is 8 hours, the drying temperature is 250°C, the calcination temperature is 900-1200°C, and the time is 2-8 hours;

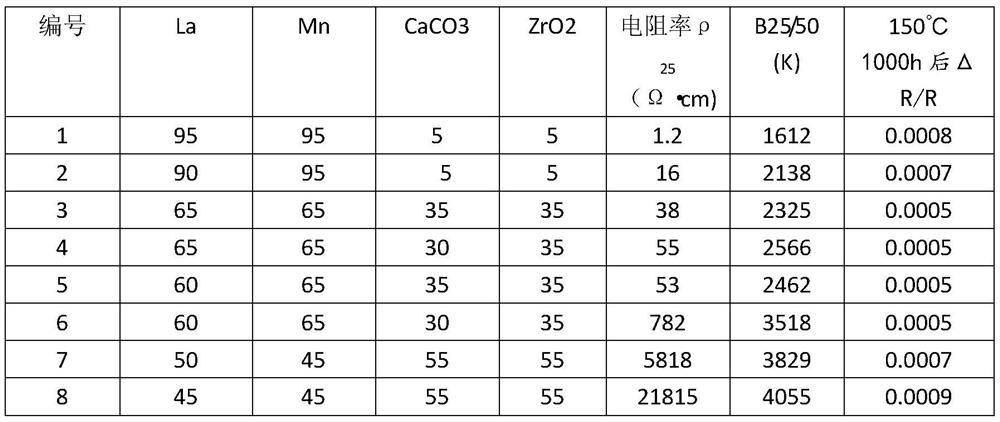

[0021] Adopt each embodiment of above-mentioned method and performance to refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com