Benzimidazole-substituted polyimide, preparation method thereof, benzimidazole-substituted polyimide film, and preparation method and application of film

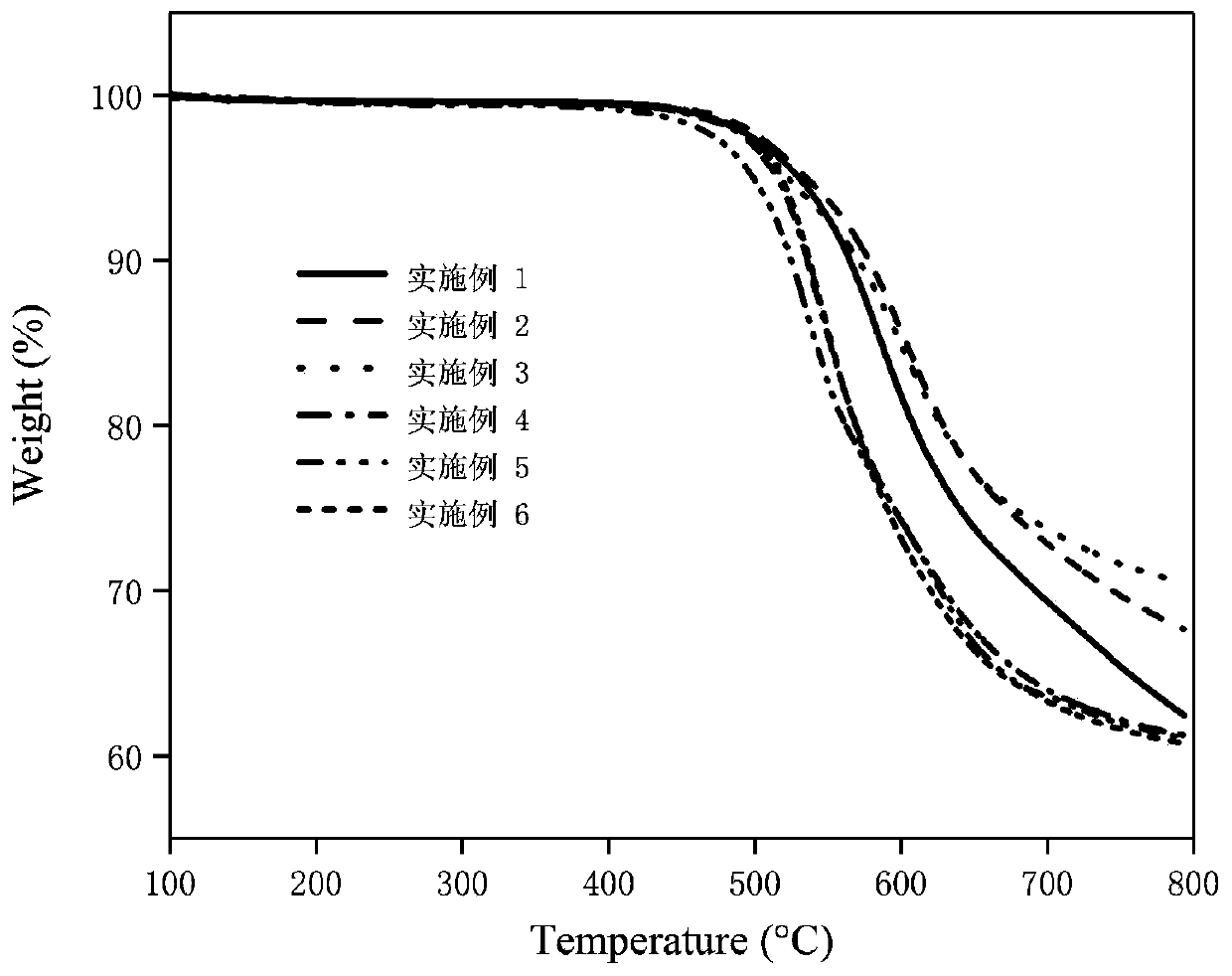

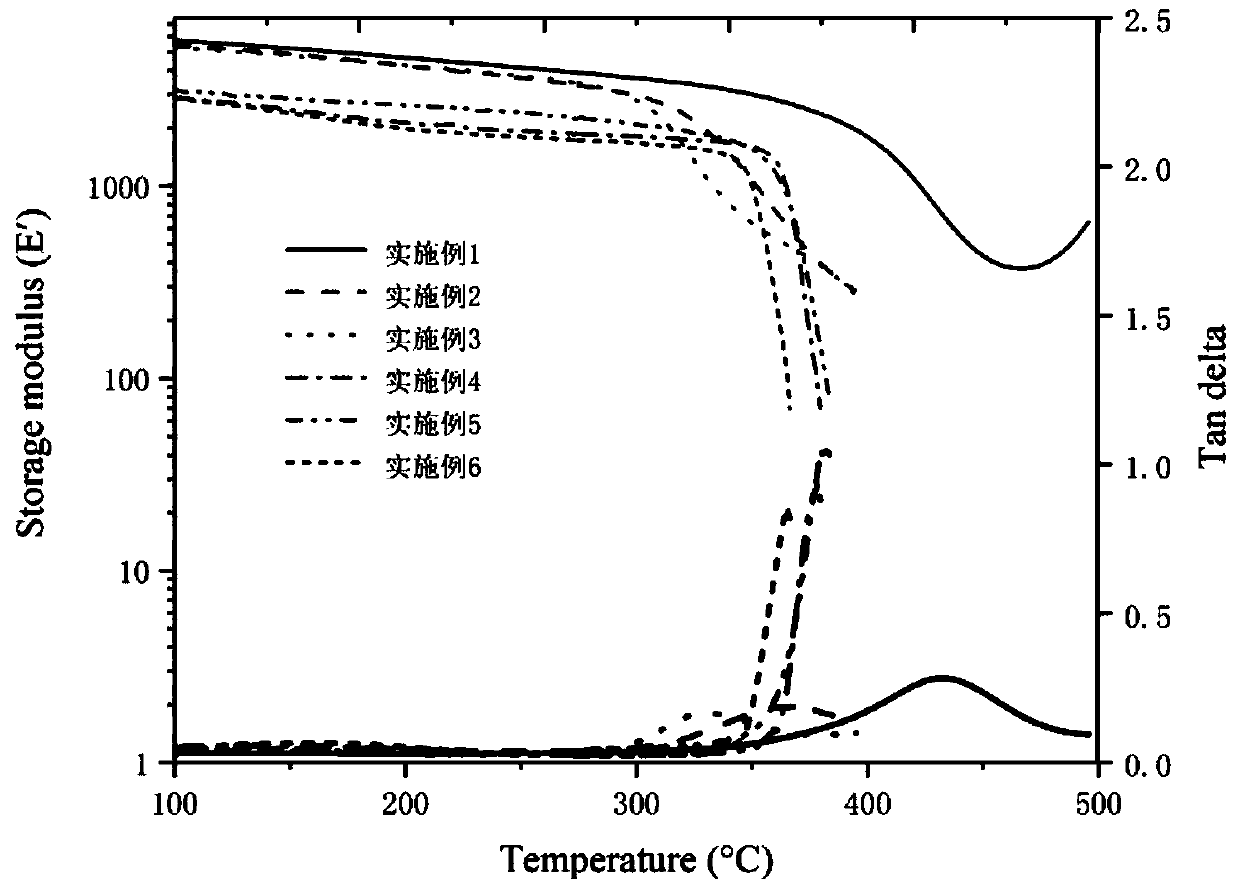

A technology of benzimidazole polyamic acid and polyimide film is applied in the field of benzimidazole-substituted polyimide film and preparation, and can solve the problems affecting the performance and yield of flexible circuit boards, and the water absorption of polyimide. High rate, secondary processing influence and other problems, to achieve the effect of good dimensional stability, excellent mechanical properties, high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

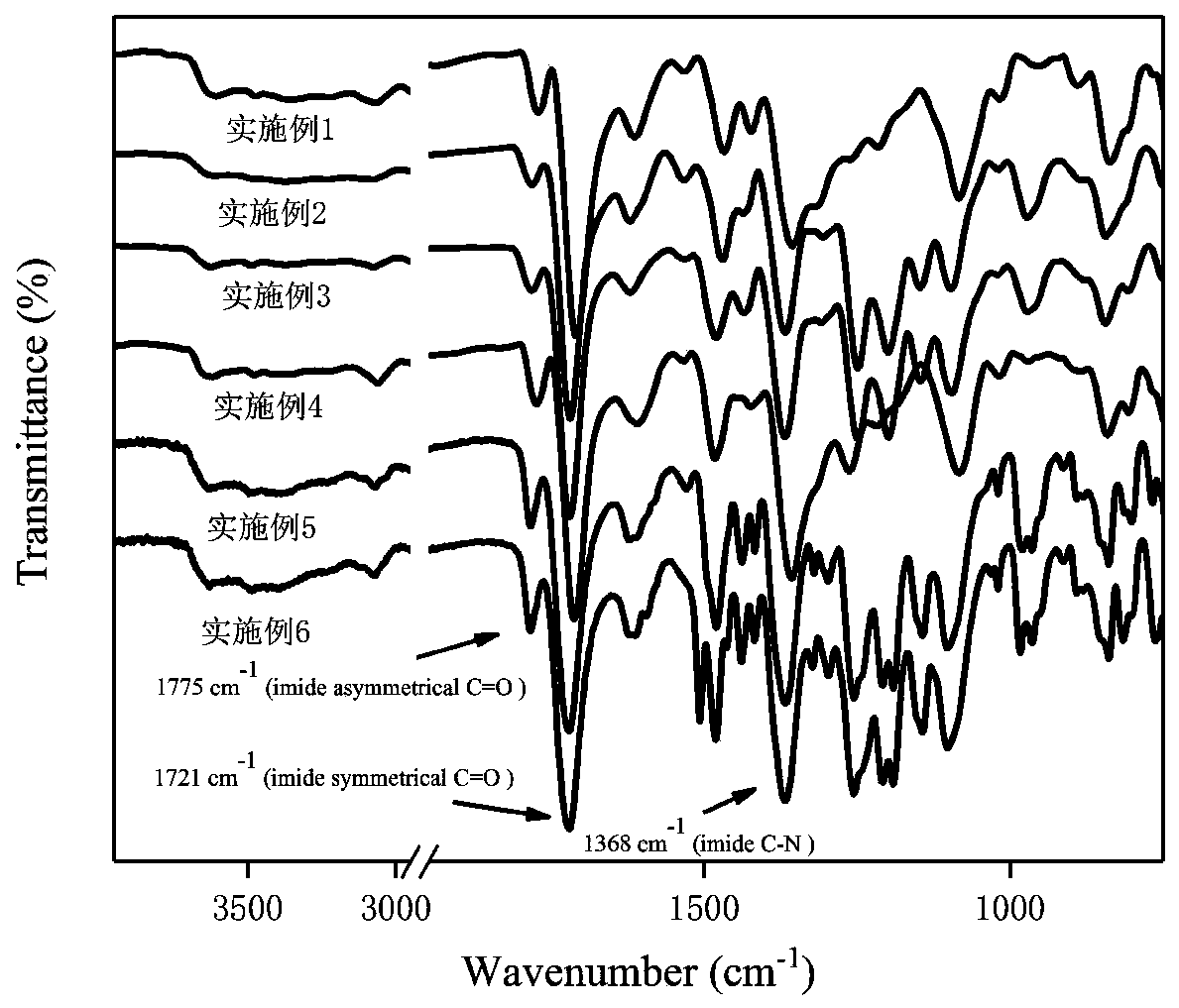

[0058] The present invention provides the preparation method of the benzimidazole substituted polyimide described in above-mentioned technical scheme, comprises the following steps:

[0059] Under protective atmosphere conditions, diamine monomers, dianhydride monomers and solvents are mixed for polymerization to obtain benzimidazole polyamic acid;

[0060] Carrying out imidization reaction of the benzimidazole polyamic acid to obtain a benzimidazole-substituted polyimide;

[0061] The diamine monomer has a structure shown in formula A-1 or formula A-2:

[0062]

[0063] In formula A-1 and formula A-2, R 1 Any of the following substituents are included:

[0064]

[0065] The dianhydride monomer includes any one or both of the following structural formulas:

[0066]

[0067] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0068] The invention mixes diamin...

Embodiment 1

[0101]

[0102] Under nitrogen protection conditions, add 10g of 6-amino-2-(4-aminobenzene)-1-methylbenzimidazole to 50g of N,N-dimethylacetamide, stir and mix under ice bath conditions, add 9.1601 g pyromellitic dianhydride continued to stir, and the viscosity of the system increased with the prolongation of the stirring time, and 58.6 g of N,N-dimethylacetamide was added, and the solid content of the resulting system was 15.0 wt%. Start the timing, after the polymerization reaction for 10 hours, remove the reaction device and seal the bottle mouth, and put it in a refrigerator at -20°C for 24 hours to freeze and defoam to obtain a uniform yellow benzimidazole polyamic acid glue (PAA glue) ;

[0103] Thaw the PAA glue solution at room temperature for 30 minutes, apply a film on a clean and flat glass sheet with a thickness of 400 μm, transfer the coated glass sheet to a blast oven, and set the temperature at 80°C / 1h+140°C / 1h+200°C / 1h temperature rise program to remove th...

Embodiment 2

[0105]

[0106] Under nitrogen protection conditions, 10g of 6-amino-2-(4-aminobenzene)-1-methylbenzimidazole was added to 50g of N,N-dimethylacetamide, stirred and mixed under ice bath conditions, and 12.3471 g3,3',4,4'-biphenyltetracarboxylic dianhydride continued to stir, and the viscosity of the system increased with the prolongation of the stirring time, and 76.6g of N,N-dimethylacetamide was added, and the solid The content is 15.0wt%, and the timing starts from the completion of adding the solvent. After 10 hours of polymerization reaction, remove the reaction device and seal the bottle mouth, and put it in a refrigerator at -20°C for 24 hours to freeze and defoam, and obtain uniform yellow benzimidazole Polyamic acid glue (PAA glue);

[0107] Thaw the PAA glue solution at room temperature for 30 minutes, apply a film on a clean and flat glass sheet with a thickness of 400 μm, transfer the coated glass sheet to a blast oven, and set the temperature at 80°C / 1h+140°C / 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com