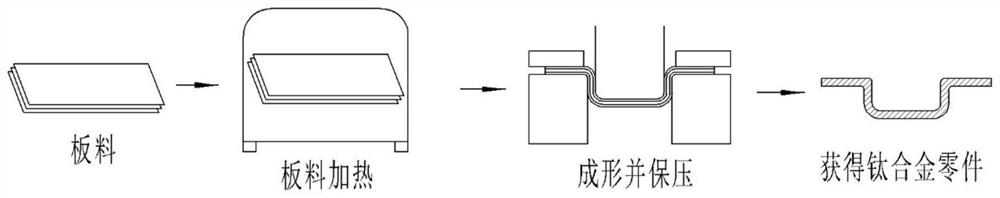

A hot stamping forming process of titanium alloy multilayer plate

A technology of hot stamping and titanium alloy, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc. It can solve the problems of poor dimensional accuracy of parts, large springback, and the temperature of the sheet metal cannot meet the expected value, etc., and achieve the springback angle Reduce, facilitate large-scale and automated production, and achieve the effect of large-scale and automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In order to illustrate the advantage of slow temperature drop of the titanium alloy plate during the transfer process under the process of the present invention, the temperature of the titanium alloy plate is measured. The specific implementation is as follows:

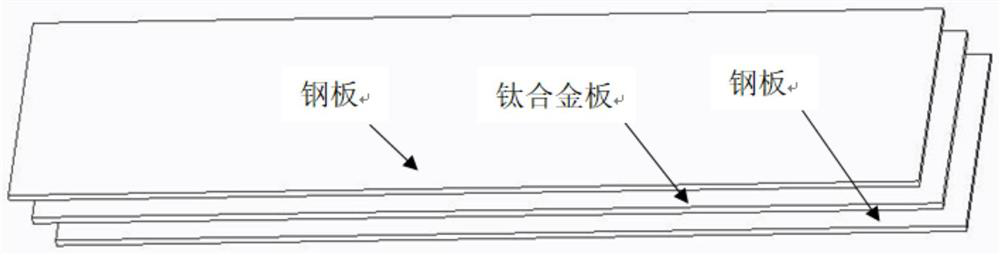

[0027] The steel plate is 1.4mm thick 22MnB5 high-strength steel plate, and the titanium alloy plate is 1.7mm thick Ti6Al4V. Cut the steel plate and titanium alloy plate into discs with a diameter of 100mm, and drill a hole with a depth of 50mm and a diameter of 1mm on the titanium alloy plate; then insert the K-type thermocouple into the hole that has been punched on the titanium alloy .

[0028] (1) First, measure the temperature change of the single-layer titanium alloy plate, put the titanium alloy plate into the heating furnace, heat it to 850°C, keep it warm for 5 minutes, take it out and cool it in the air, and connect it with a K-type thermocouple The temperature measuring instrument monitors the temp...

Embodiment 2

[0033] The 1.4mm thick 22MnB5 high-strength steel plate is selected, and the titanium alloy plate is 1.7mm thick Ti6Al4V. Cut the steel plate and titanium alloy plate into circular plate-sized specimens with a diameter of 100mm; figure 2 shown), after the sheet is heated to 850°C, it is taken out and placed on a spherical mold for hot stamping at a stamping speed of 35mm / s.

[0034] The stamping depth of the titanium alloy sheet obtained in this embodiment is 35mm, and compared with the single-layer sheet stamping forming process, the part depth is increased by 133.3%. Part formability has been greatly improved.

Embodiment 3

[0036] In this embodiment, a 1.4mm thick 22MnB5 high-strength steel plate is selected, and a 1.7mm thick Ti6Al4V is selected as a titanium alloy plate. Cut the steel plate and titanium alloy plate into 180mm×50mm samples; then clamp the sample in the order of steel plate-titanium alloy plate-steel plate and put it into the heating furnace for heating. After heating to 900°C, keep it warm for 5 minutes and take it out. The steel plate and titanium alloy plate are transferred to the U-shaped part mold for stamping test, and the pressure is maintained after stamping and forming, until the titanium alloy plate is fully cooled, and the formed part is taken out.

[0037] The U-shaped part obtained by this embodiment has a small springback angle of 0.45°, which is 83% less than that of the single-layer plate forming process. The rebound angle is much smaller than that of U-shaped parts formed by conventional hot stamping and cold die quenching process.

[0038] The process of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com