A quantitative chemical analysis method for two-component blended fiber products of Yike silk and cotton

A blended fiber and two-component technology, which is applied to the quantitative chemical analysis of blended fiber products, the field of quantitative chemical analysis of two-component blended fiber products of ike silk fiber and cotton fiber, can solve the problem that there is no report of ike silk fiber, no R & D and other problems to achieve the effect of saving procedures, small errors, and good balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

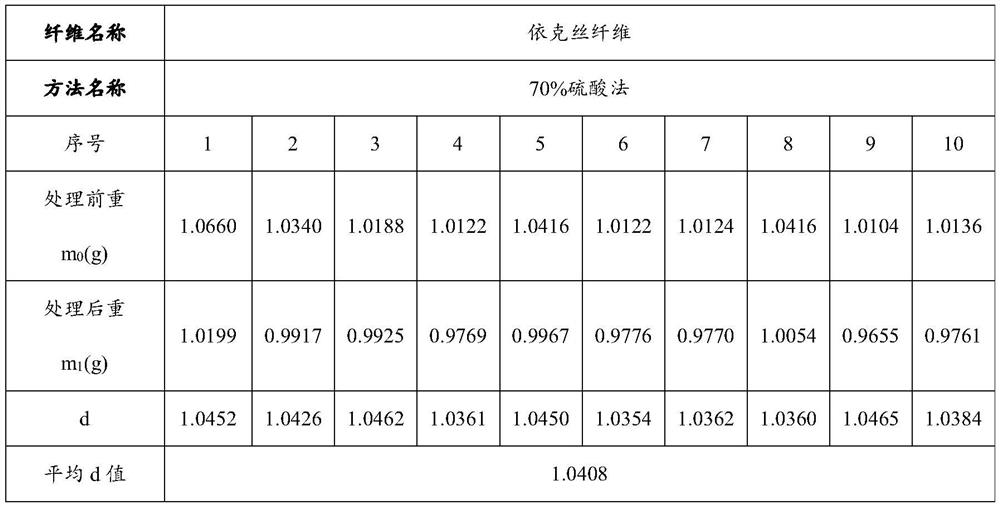

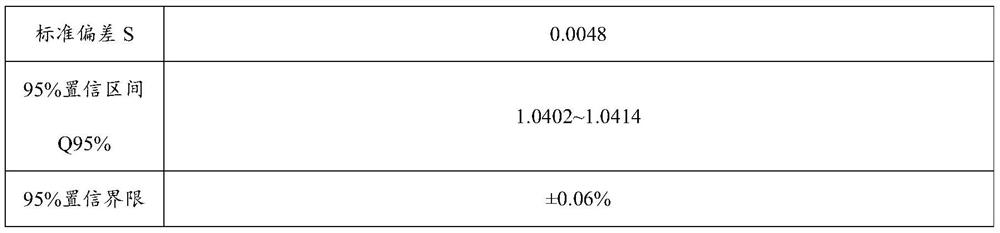

[0034] Embodiment 1: the first group of balance tests

[0035] 1. Reagents

[0036] All reagents are analytically pure, and the test water is the third-grade water in the national standard GB6682.

[0037] 1. Petroleum ether: the heating process is 40-60°C;

[0038] 2. Dilute ammonia solution: add 80mL concentrated ammonia water and dilute to 1L with water;

[0039] 3. Sulfuric acid solution: the mass concentration is 68% to 72%.

[0040] 2. Instrument

[0041] 1. Soxhlet extractor: receiving bottle 250mL;

[0042] 2. Constant temperature oscillator: the temperature adjustment range is from room temperature to 99°C;

[0043] 3. Vacuum pump: the speed is 1400r / min;

[0044] 4. Electric blast drying oven: keep the temperature at 105±3°C;

[0045] 5. Erlenmeyer flask with stopper: capacity 250mL;

[0046] 6. Glass sand core funnel: capacity 30mL ~ 50mL, pore diameter 90μm ~ 150μm;

[0047] 7. Dryer: equipped with color-changing silica gel;

[0048] 8. Weighing bottles, ...

Embodiment 2

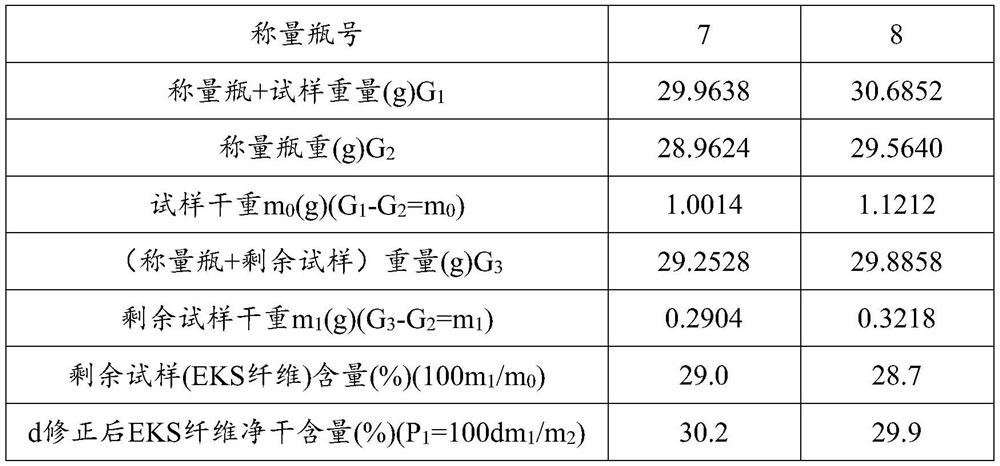

[0063] Embodiment 2: the second group of balance tests

[0064] Test data and calculated results are shown in Table 3, and others are the same as in Example 1.

[0065] Table 3 The second group of balance test results

[0066] Weighing bottle number 3 4 Weighing bottle + sample weight (g) G 1

Embodiment 3

[0067] Embodiment 3: the third group of balance tests

[0068] Test data and calculated results are shown in Table 4, and others are the same as in Example 1.

[0069] Table 4 The third group of balance test results

[0070] Weighing bottle number 5 6 Weighing bottle + sample weight (g) G 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com