A kind of preparation method of bamboo fiber base degradable environmental protection material

An environmentally friendly material, bamboo fiber-based technology, applied in the field of preparation of bamboo fiber-based degradable environmentally friendly materials, can solve the problems of easy-to-growth mold and mildew, and easy-to-corrosion of environmentally friendly materials, so as to reduce thermal degradation, improve appearance and mechanical properties, molecular well-arranged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

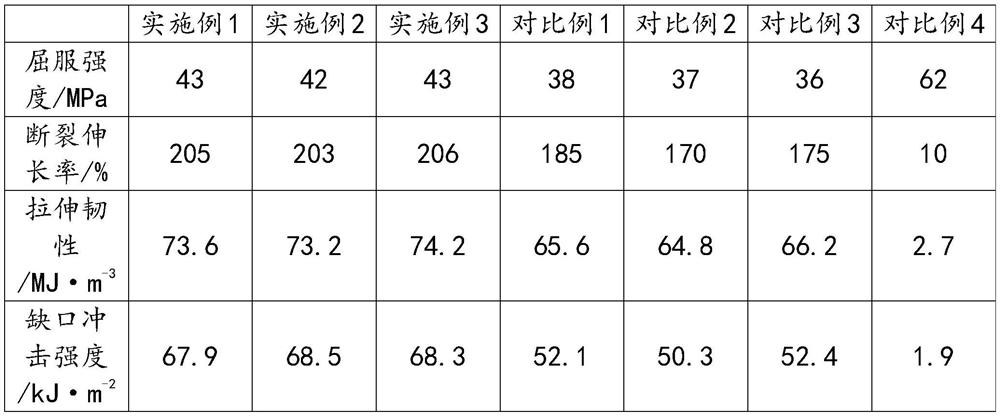

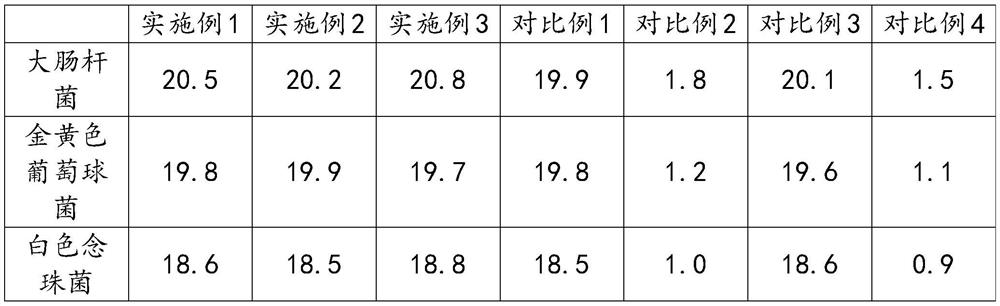

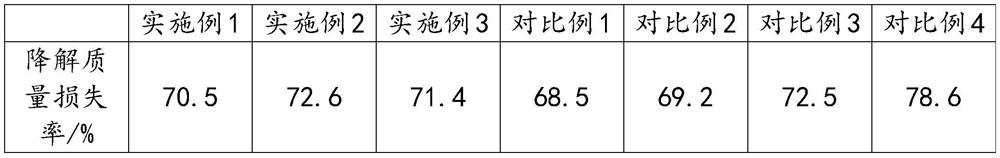

Examples

preparation example Construction

[0024]A method for preparing a bamboo fibryl-degradable environmental material, including the following steps:

[0025]Step S1, according to the following weight: 70-80 parts of polylactic acid, 8-10 pieces of ethylene / acrylate / methacrylate, 14-16 modified bamboo fibers, 0.7-0.9 parts of tonal powder , Silane coupling agent 0.01-0.02 parts, no water ethanol 4-5 parts weigh the feed;

[0026]Step S2, first discharged the polylactic acid, ethylene / acrylate / methacrylate, and the trihydridate of 80 ° C, 40 ° C, respectively;

[0027]Step S3, weighing 6% polylactic acid and ethylene / acrylate / methacrylate dehydrates with unfilling 40 min under the condition of 250 ° C, rotation speed 100R / min, sufficiently reacted, remove the reaction after the reaction, cut Broken, cool, resulting in a pre-reactive;

[0028]Step S4, dissolve the silane coupling in anhydrous ethanol, stir well, slowly add talc powder, first temperature, stir for 30-40 min, then add 15-20 min, filter, dry to constant wei...

Embodiment 1

[0040]A method for preparing a bamboo fibryl-degradable environmental material, including the following steps:

[0041]Step S1, according to the following weight: 70 parts of the polylactic acid, 8 parts of ethylene / acrylate / methacrylate, 14 parts of the triumphant polymer, 14 parts of the bamboo fiber, 0.7 tonal powder, silane coupling agent KH5500.01 Add 4 parts of the combination of no water ethanol;

[0042]Step S2, first discharged the polylactic acid, ethylene / acrylate / methacrylate, and the trihydridate of 80 ° C, 40 ° C, respectively;

[0043]Step S3, weighing 6% polylactic acid and ethylene / acrylate / methacrylate dehydrates with unfilling 40 min under the condition of 250 ° C, rotation speed 100R / min, sufficiently reacted, remove the reaction after the reaction, cut Broken, cool, resulting in a pre-reactive;

[0044]Step S4, dissolve the silane coupling agent KH550 in anhydrous ethanol, stir well, slowly add talc powder, first temperature, stir for 200m, then 15 min, filter...

Embodiment 2

[0047]A method for preparing a bamboo fibryl-degradable environmental material, including the following steps:

[0048]Step S1, according to the following weight: 75 parts of polylactic acid, 9 servants of ethylene / acrylate / methacrylate, 15 copies of the retrogenous bamboo fiber, 0.8 tonal powder, silane coupling agent 5700.01-0.02 4.5 copies of no water ethanol;

[0049]Step S2, first discharged the polylactic acid, ethylene / acrylate / methacrylate, and the trihydridate of 80 ° C, 40 ° C, respectively;

[0050]Step S3, weighing 6% polylactic acid and ethylene / acrylate / methacrylate dehydrates with unfilling 40 min under the condition of 250 ° C, rotation speed 100R / min, sufficiently reacted, remove the reaction after the reaction, cut Broken, cool, resulting in a pre-reactive;

[0051]Step S4, dissolve the silane coupling agent KH570 in anhydrous ethanol, stir well, add talc powder, first temperature, 200r / min for 35min, then ultrasound 18min, filter, dry to constant weight, to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com