Viscous-elastic material-based processing inductive grinding pad

A grinding pad and viscoelastic technology, applied in the field of grinding pads, can solve problems such as burden, damaged layer, poor surface quality, equipment damage, etc., and achieve the effects of improving processing efficiency, improving grinding accuracy, and increasing grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited to these examples.

[0049] refer to figure 2 Use methyl silicone resin as adhesive 3, add diamond abrasive grains with a particle size of 1 micron as abrasive 4, stir evenly, and fill it on the surface of the non-woven polishing pad to prepare a processing condition-sensitive polishing pad . The material to be ground is a 2-inch SiC substrate. Table 1 below lists the grinding pad grinding conditions:

[0050] Table 1 Processing conditions based on viscoelastic materials Inductive polishing pad grinding conditions

[0051]

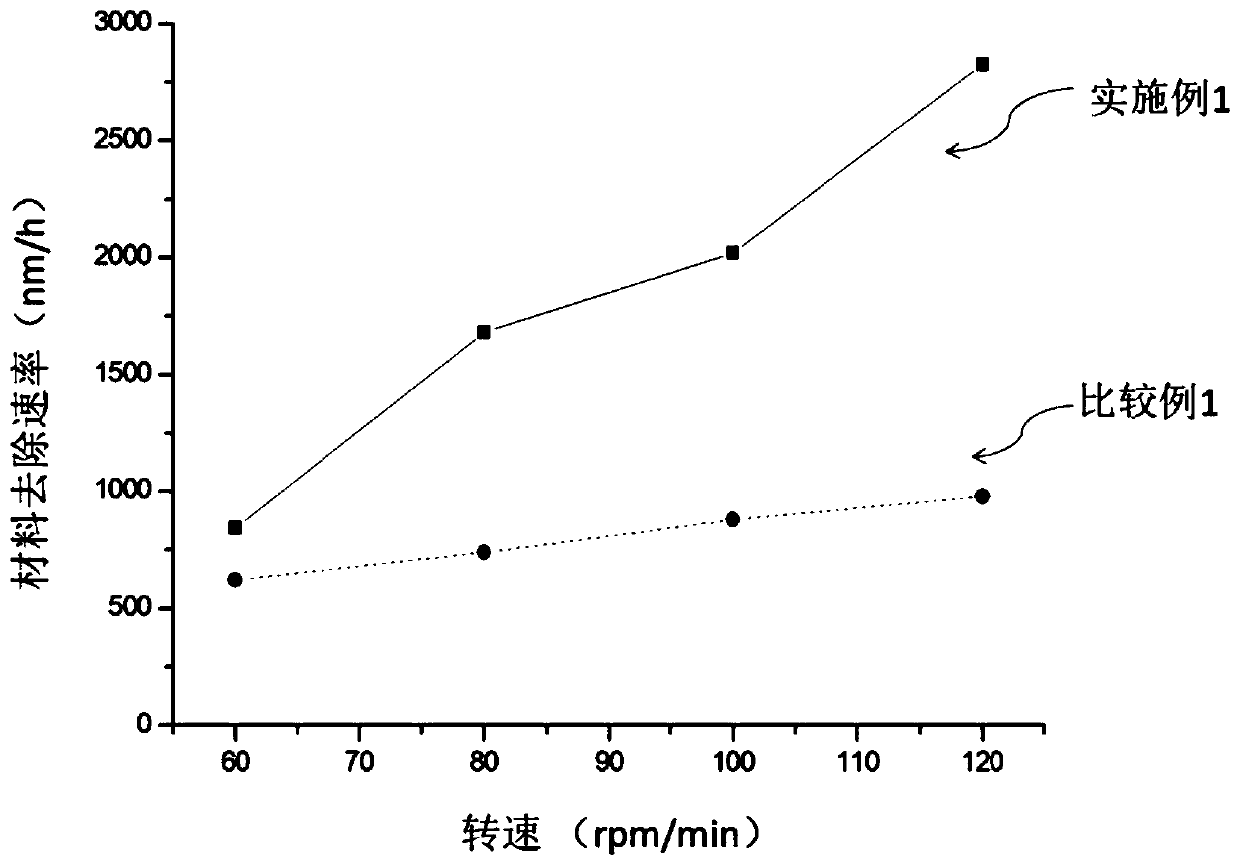

[0052] Use processing condition-sensitive grinding pads to grind SiC substrates at different speeds for 1 hour. It can be found that when the rotation speed of the grinding disc is continuously increased, the material removal efficiency is greatly improved, and the surface roughness of the SiC substrate after processing...

Embodiment 2

[0056] as attached image 3 As shown, the material of the adhesive 3 is methyl silicone resin, and diamond abrasive grains with a particle size of 1 micron are added to it, and after stirring evenly, it is filled and coated on the surface of the non-woven polishing pad to prepare a polishing pad with a processing condition induction. . The material to be ground is a 2-inch SiC substrate. Table 2 below lists the grinding pad grinding conditions:

[0057] Table 2 Processing conditions based on viscoelastic materials Induction polishing pad grinding conditions

[0058]

[0059] Using a processing condition-sensitive polishing pad, the SiC substrate was ground for 1 hour under different pressure conditions. It can be found that when the processing pressure increases, the material removal efficiency is significantly improved, and the surface roughness of the SiC substrate after processing can reach about 1nm. It can be seen that the new polishing pad responds strongly to the ...

Embodiment 3

[0063] as attached Figure 4 As shown, the viscoelastic material methyl silicone resin is used, and diamond abrasive grains with a particle size of 1 micron are added to it. After stirring evenly, it is filled and coated on the surface of the non-woven polishing pad to prepare a polishing pad with processing condition sensitivity. The material to be ground is a 2-inch sapphire substrate. Table 3 below lists the grinding pad grinding conditions:

[0064] Table 3 Processing conditions based on viscoelastic materials Induction polishing pad grinding conditions

[0065]

[0066] Using the processing condition induction grinding pad, the sapphire substrate was polished for 1 hour under different speed conditions. It can be found that when the processing speed increases, the material removal efficiency is significantly improved. It can be seen that the new polishing pad also has obvious effects on the processing of sapphire substrates, and increasing the processing speed can al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com