Production method of fluorine-containing cyanate ester resin

A fluorocyanate-containing resin technology is applied in the field of preparation of fluorocyanate-containing resins, which can solve the problems of lowering polymer rigidity, lowering rigidity, lowering flame retardant performance and thermal stability performance, etc., and improving high temperature resistance. The effect of improving flammability, improving flexibility and reducing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 350 g of methyl acrylate to 1 L of 50% hydrochloric acid solution, stir for 5-6 hours, add the obtained product to chloroform for extraction, and then carry out vacuum distillation to obtain methyl chloroacrylate with a yield of 91.3% .

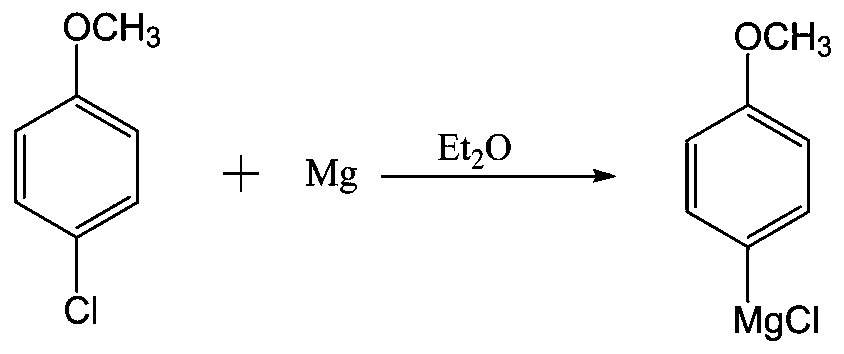

[0029] Add 143g of 4-chloroanisole and ether solution into the reflux reaction vessel, then slowly add magnesium chips soaked in ether therein, wherein the amount added is based on the mass of magnesium chips and 25g magnesium chips are added, and the solution boils slightly during the addition process. After the addition is complete, react until the solution does not boil, then keep stirring for 20-30 minutes, then filter to remove the unreacted magnesium powder, and carry out vacuum distillation on the filtrate to obtain the Grignard reagent with a yield of 87.6%.

Embodiment 2

[0031] A kind of preparation method of fluorine-containing cyanate ester resin, concrete preparation process is as follows:

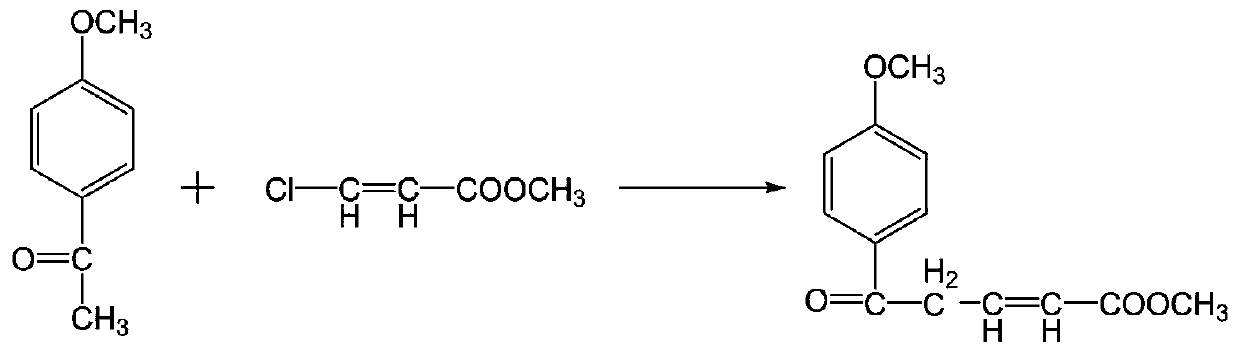

[0032] The first step: Weigh a certain amount of p-methoxyacetophenone and dissolve it in ethanol to obtain a p-methoxyacetophenone solution with a concentration of 65%, and add 1L of p-methoxyacetophenone solution to the reaction kettle , stir and mix evenly, heat up to 60-70°C, then add 100g of sodium ethoxide and 510g of methyl chloroacrylate prepared in Example 1 into the reaction vessel, react at constant temperature for 15-18h, and then carry out vacuum distillation to obtain biscarbonyl unsaturated monomers;

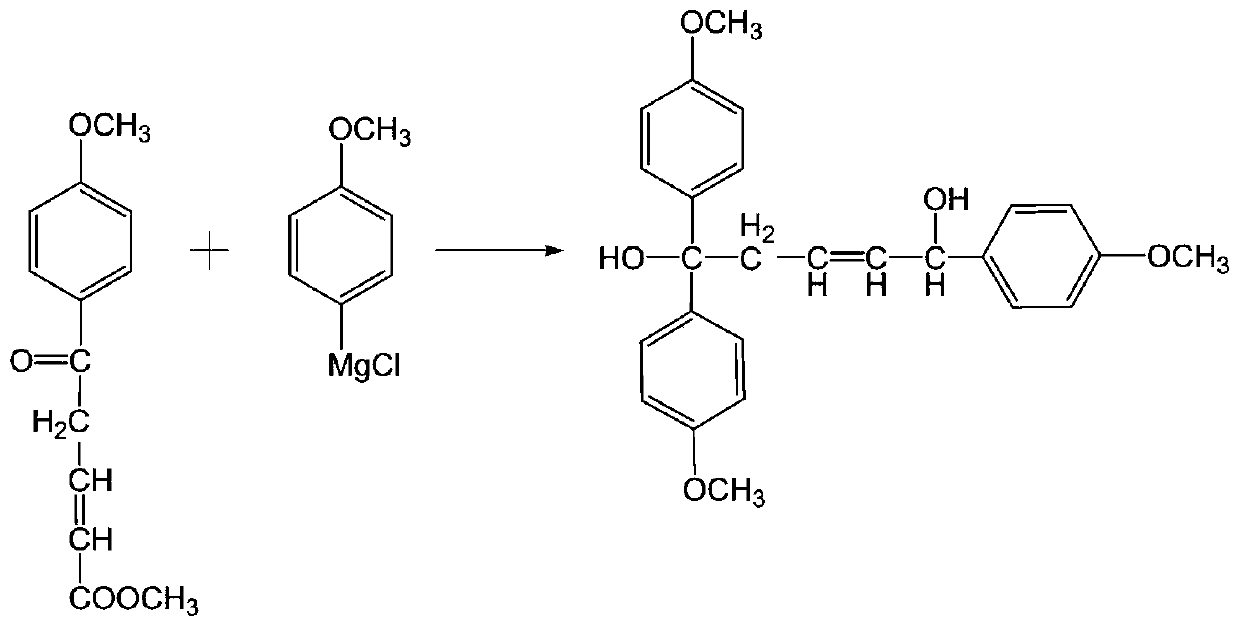

[0033] In the second step, 1 kg of the dicarbonyl unsaturated monomer prepared in the first step is added in the dimethyl sulfoxide solution, and after stirring and dissolving, 0.705 kg of the Grignard reagent prepared in Example 1 is added thereto, and the stirring reaction at normal temperature is 5- 6h, then carry out vacuum distillatio...

Embodiment 3

[0039] A kind of preparation method of fluorine-containing cyanate ester resin, concrete preparation process is as follows:

[0040] The first step: Weigh a certain amount of p-methoxyacetophenone and dissolve it in ethanol to obtain a p-methoxyacetophenone solution with a concentration of 65%, and add 1L of p-methoxyacetophenone solution to the reaction kettle , stir and mix evenly, heat up to 60-70°C, then add 100g of sodium ethoxide and 510g of methyl chloroacrylate prepared in Example 1 into the reaction vessel, react at constant temperature for 15-18h, and then carry out vacuum distillation to obtain biscarbonyl unsaturated monomers;

[0041] In the second step, 1 kg of the dicarbonyl unsaturated monomer prepared in the first step is added in the dimethyl sulfoxide solution, and after stirring and dissolving, 0.705 kg of the Grignard reagent prepared in Example 1 is added thereto, and the stirring reaction at normal temperature is 5- 6h, then carry out vacuum distillatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crimp elongation | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com