Hydrophilic/hydrophobic polyacrylamide and polystyrene interpenetrating polymer network and application thereof

A polyacrylamide and interpenetrating polymer technology, which is applied in the field of hydrophilic/hydrophobic polyacrylamide and polystyrene interpenetrating polymer network, can solve the problems of poor adsorption performance of hydrophilic inhibitors and achieve elution regeneration Easy, reduced content, environmentally friendly and green effect in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of hydrophilic / hydrophobic polyacrylamide and polystyrene interpenetrating polymer network

[0032] Prepare hydrophilic / hydrophobic polyacrylamide and polystyrene interpenetrating polymer network according to the following steps:

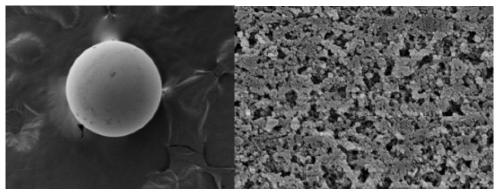

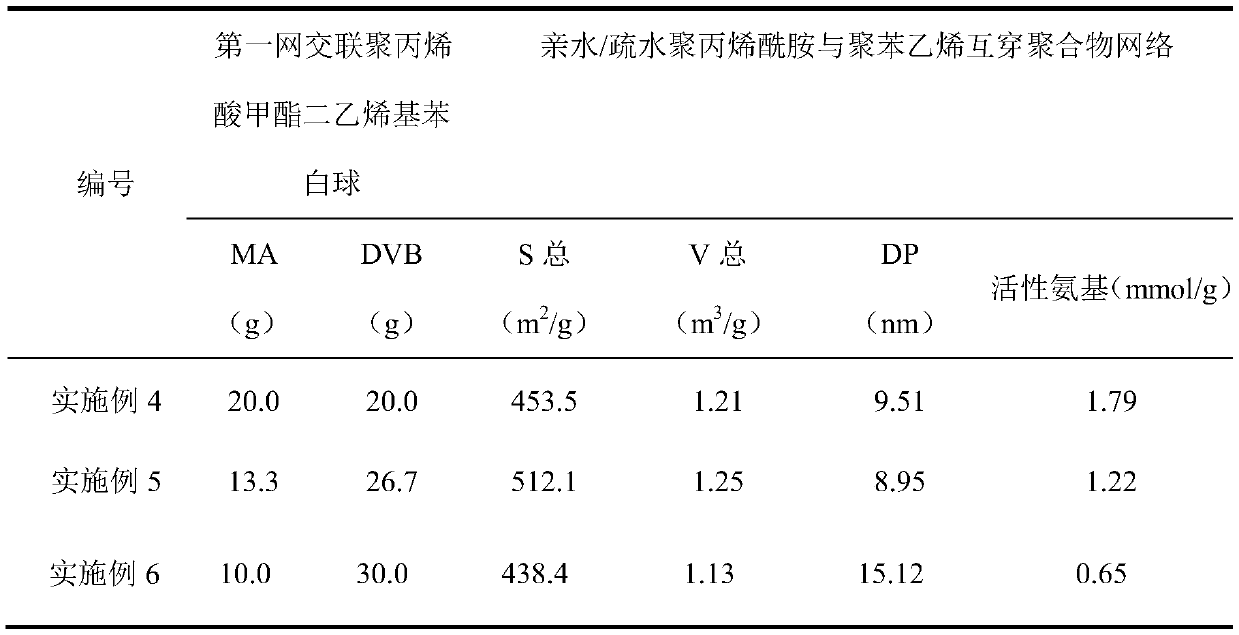

[0033] 1) Preparation of the first network of cross-linked polymethyl acrylate divinylbenzene white balls by suspension polymerization

[0034]Add 240mL of the water phase (the water phase contains 1.0% polyvinyl alcohol and 3-5 drops of 1% methylene blue solution) into a 500mL three-necked flask equipped with a mechanical stirrer, a thermometer and a serpentine condenser. After heating to 50°C in an oil bath, add the oil phase to the water phase (add 26.7 g of methyl acrylate monomer, 13.3 g of divinylbenzene, 20 g of toluene, 20 g of n-heptane and 0.4 g of benzoyl peroxide ), after feeding nitrogen for 5 minutes, adjust the stirring speed to 160 rpm to control the size of oil droplets. Then slowly raise the temperature to ...

Embodiment 2

[0047] Compared with Example 1, the difference is: in the process of preparing hydrophilic / hydrophobic polyacrylamide and polystyrene interpenetrating polymer network, the mass ratio of styrene and divinylbenzene in step (2) is 3 : 1, in the step (3), the polyethylene polyamine is triethylenetetramine, and the quality of triethylenetetramine is twice that of the polymethylacrylate polystyrene interpenetrating polymer network, and the amination reaction is carried out at 140° C. for 8 hours.

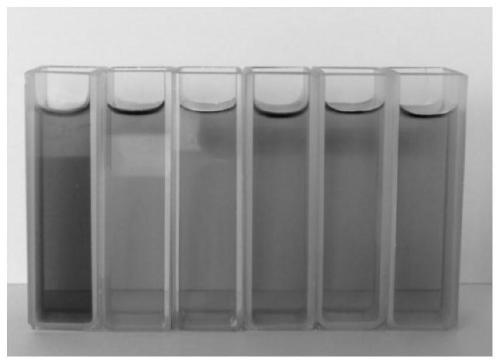

[0048] The above-mentioned hydrophilic / hydrophobic polyacrylamide and polystyrene interpenetrating polymer network is used to remove fermentation inhibitors from lignocellulose hydrolyzate, and the specific steps are:

[0049] 1) Adjust the pH of the rice straw hydrolyzate to 1 by taking sodium hydroxide, and filter to obtain a supernatant. It was determined that the absorbance of the supernatant at 540nm was 0.921, composed of glucose 11.65g / L, xylose 23.98g / L, arabinose 3.21g / L, formic ...

Embodiment 3

[0052] Compared with Example 1, the difference is: in the process of preparing hydrophilic / hydrophobic polyacrylamide and polystyrene interpenetrating polymer network, the mass ratio of styrene and divinylbenzene in step (2) is 1 : 3, in the step (3), the polyethylene polyamine is triethylenetetramine, and the quality of triethylenetetramine is 3 times that of the polymethylacrylate polystyrene interpenetrating polymer network, and the amination reaction is carried out at 150°C for 12h.

[0053] The above-mentioned hydrophilic / hydrophobic polyacrylamide and polystyrene interpenetrating polymer network is used to remove fermentation inhibitors from lignocellulose hydrolyzate, and the specific steps are:

[0054] 1) Adjust the pH of the wheat straw hydrolyzate to 3 by taking potassium hydroxide, and filter to obtain a supernatant. It was determined that the absorbance of the supernatant at 540nm was 0.783, composed of glucose 5.02g / L, xylose 22.13g / L, arabinose 1.73g / L, formic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com