Preparation method of high-purity hypocrellin

A high-purity technology for oleocanthal, applied in quinone separation/purification, resistance to vector-borne diseases, organic chemistry, etc., can solve the problems of undisclosed purity of crystals, cannot be reused, and difficult to regenerate silica gel, and achieves production safety. The effect of improved performance, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

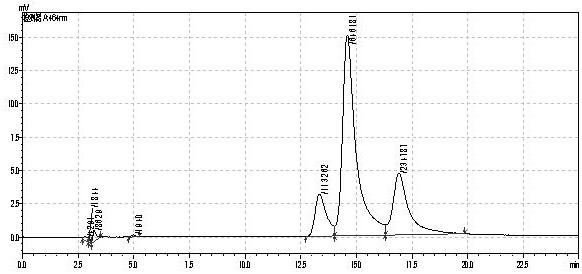

Image

Examples

Embodiment 1

[0028] The preparation method of high-purity hypocrellin comprises the following steps:

[0029] (1) Take the solid-state fermented product of bamboo yellow fungus as raw material, weigh 50g and put it in the extractor, add ethanol solution, heat reflux at 75°C to extract twice, add 500ml 95% v / v ethanol solution for extraction for 1 hour each time; combine the extraction solution, reclaiming ethanol to obtain 10.2 g of hypocretin crude extract. After testing, the purity of hypocretin in the crude extract is 4.5%.

[0030] The preparation method of the solid-state fermented product of bamboo yellow fungus:

[0031] ①Strain source: The strain was isolated from wild bamboo yellow by our unit, and has been preserved in the China General Microorganism Culture Collection Center with the preservation number CGMCC No.18808 and the preservation date is December 02, 2019.

[0032] ② Preparation of seed inoculum: the medium used is PDB medium. After the culture medium was sterilized,...

Embodiment 2

[0040] The difference between the high-purity hypocretin preparation method and Example 1 is that the column height of the macroporous adsorption resin column ADS21 is 30 cm. Other steps are all the same as in Example 1.

[0041] After testing, the purity of hypocrellin was 73.5%.

Embodiment 3

[0043] The difference between the high-purity hypocrellin preparation method and Example 1 is that a macroporous adsorption resin column D101 is used, with a column height of 30 cm and a diameter of 3 cm. Other steps are all the same as in Example 1.

[0044] After testing, the purity of hypocrellin was 53.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com