Co@NC high-dispersion core-shell structure catalyst, and preparation method and application of catalyst

A core-shell structure and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, structural parts, etc., can solve the problems that the preparation process needs to be further simplified, the size range of metal particles is large, and it is unfavorable for large-scale preparation. Achieve the effects of low raw material prices, inhibit growth and agglomeration, and facilitate large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

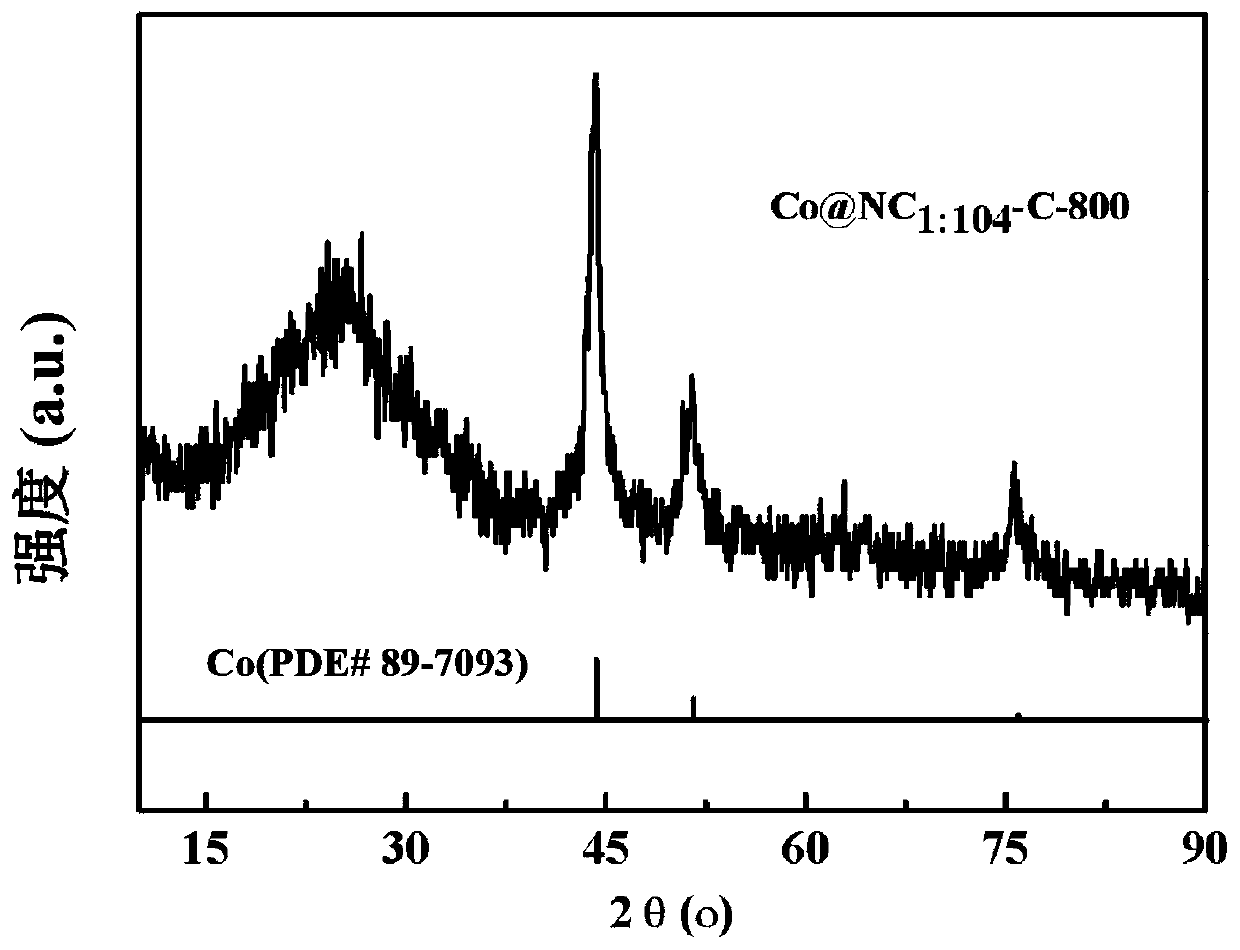

[0041] Example 1: Co@NC 1:104 -C-800(Co refers to Co(NO 3 )·6H 2 O, NC is dicyandiamine, 1:104 is Co(NO 3 )·6H 2 The molar ratio of O to dicyandiamide, C is glucose, the mass ratio of NC to C is 15:1, 800 means the pyrolysis temperature is 800°C)

[0042] 0.05g Co(NO 3 )·6H 2 O, 1.5g of dicyandiamide and 0.1g of glucose were dissolved in 20ml of deionized water to obtain solution A; stirred in an oil bath at 80°C for 3 hours to fully dissolve and mix uniformly to obtain solution B; put the uniformly mixed solution in an air drying oven Dry at 80°C for 12 hours to obtain the catalyst precursor; place the dried precursor in a mortar, grind it evenly, place it in a quartz boat, and place it under nitrogen protection at 30°C for min -1 The temperature was programmed to 800 °C for 2 h, and Co@NC was obtained after natural cooling. 1:104 -C-800 catalyst.

Embodiment 2

[0043] Example 2: Co@NC 1:104 -C-700 (Co refers to Co(NO 3 )·6H 2 O, NC is dicyandiamine, 1:104 is Co(NO 3 )·6H 2 The molar ratio of O to dicyandiamide, C is glucose, the mass ratio of NC to C is 15:1, 700 means the pyrolysis temperature is 700°C)

[0044] 0.05g Co(NO 3 )·6H 2 O, 1.5g of dicyandiamide and 0.1g of glucose were dissolved in 20ml of deionized water to obtain solution A; stirred in an oil bath at 100°C for 0.5h to fully dissolve and mix uniformly to obtain solution B; the uniformly mixed solution was dried in the air Dry in the box at 80°C for 12h to obtain the catalyst precursor; place the dried precursor in a mortar, grind it evenly, place it in a quartz boat, and place it under the protection of nitrogen at 15°C for min -1 The temperature was programmed to 700°C for 45 hours, and Co@NC was obtained after natural cooling. 1:104 -C-700 catalyst.

Embodiment 3

[0045] Example 3: Co@NC 200:7 -C-900 (Co refers to Co(NO 3 )·6H 2 O, NC is dicyandiamine, 200:7 is Co(NO 3 )·6H 2 The molar ratio of O to dicyandiamide, C is glucose, the mass ratio of NC to C is 1:30, 900 means the pyrolysis temperature is 900°C)

[0046] 0.05g Co(NO 3 )·6H 2 O, 1.5g of dicyandiamide and 0.1g of glucose were dissolved in 20ml of deionized water to obtain solution A; stirred in an oil bath at 80°C for 25 hours to fully dissolve and mix uniformly to obtain solution B; dry the uniformly mixed solution in an inert atmosphere Dry in the box at 80°C for 12h to obtain the catalyst precursor; place the dried precursor in a mortar, grind it evenly, place it in a quartz boat, and place it under the protection of nitrogen at 15°C for min -1 The temperature was programmed to 900°C for 0.5h, and Co@NC was obtained after natural cooling. 1:104 -C-900 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com