Three-dimensional analysis method for non-metallic inclusions in metal material

A technology for non-metallic inclusions and metallic materials, which is used in material analysis, material analysis, and measurement devices using wave/particle radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

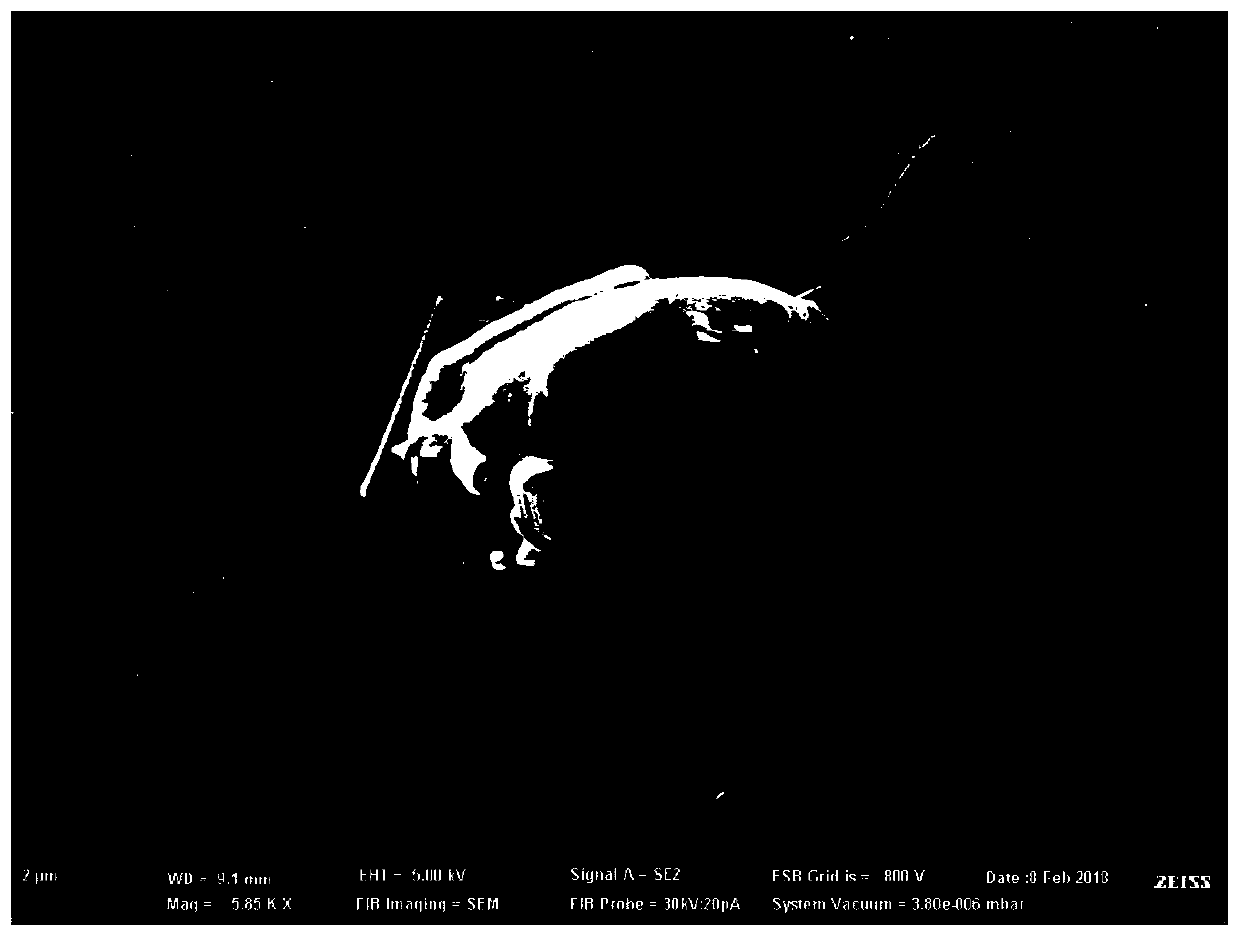

[0036] In this example, a hot-rolled 700MPa high-strength steel with a thickness of 12mm was selected, and the non-metallic inclusions in it were analyzed three-dimensionally; the instruments used included: Struers LaboSystem sample grinding machine, Struers TenuPol-5 double-spray electrolyzer, and ZEISS Auriga scanning electron microscope.

[0037] The specific analysis steps are as follows:

[0038] 1) Sample preparation

[0039] In this embodiment, two surfaces of the sample are selected for observation, so two observation surfaces need to be processed. Specific steps are as follows:

[0040] 1.1) Use a precision cutting machine to cut the hot-rolled plate sample into a block of 20mm×20mm×12mm, and further use wire cutting to cut the sample into several pieces of 20mm×20mm×0.4mm, and place the cut sample in the volume fraction Use 2% hydrochloric acid alcohol solution (the volume of hydrochloric acid is calculated as the volume of 36.5 wt% aqueous solution) to perform ult...

Embodiment 2

[0057] In this example, the same method as in Example 1 is basically used to analyze another hot-rolled 700MPa high-strength steel with a thickness of 12mm. Secondary electron imaging with a scanning electron microscope yielded image 3 (a) Image showing a flaky composite non-metallic inclusion with a raised center. The accelerating voltage was adjusted from 5KV to 15KV, and the element surface scanning analysis was carried out on the observation surface by using a scanning electron microscope equipped with an energy dispersive X-ray spectrometer (EDX), and the obtained image 3 (b)~(f), it can be seen that the protruding part of the composite inclusion center is enriched by two elements, Al and O, indicating that the center is Al 2 o 3 , the inclusions at the bottom are flake-like, rich in Ti and N, and the inclusions on the surface are TiN inclusions. The analysis shows that the TiN is Al 2 o 3 For nucleation core growth.

[0058] The present invention is based on the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com