A Calculation Method of Assembly Pose and Posture Based on Minimum Potential Energy

A calculation method and assembly position technology, applied in calculation, computer-aided design, measuring device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

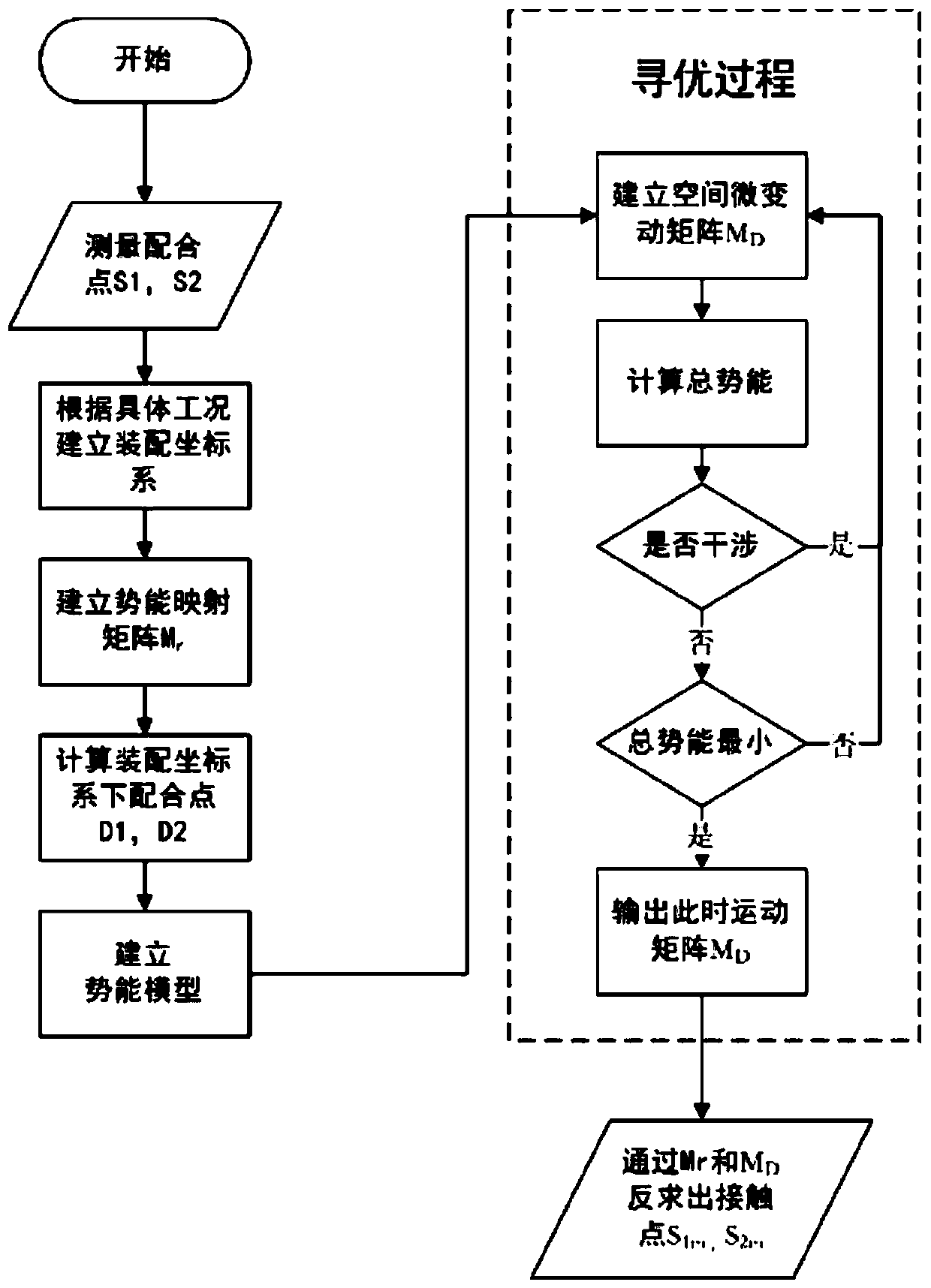

[0036] This application document provides an assembly pose calculation method based on the minimum potential energy, such as figure 1 As shown, the basic idea of this method is that after obtaining the measured surface topography data, a potential energy mapping matrix is established according to the assembly working conditions to convert the mating surface into the assembly coordinate system and represent it as a form of potential energy; The micro-movement is a variable, and the spatial variation matrix is given, and the backbone particle swarm optimization algorithm is used to find the optimal solution that minimizes the potential energy of the matching surface.

[0037] The method is specifically:

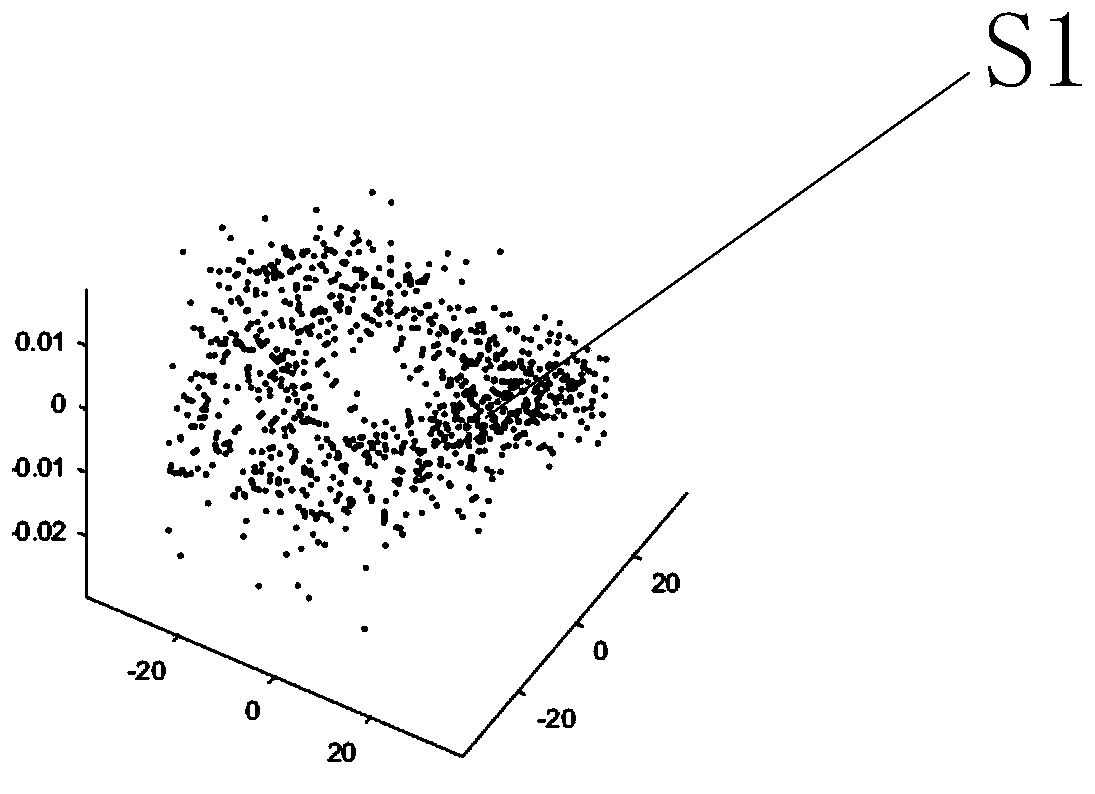

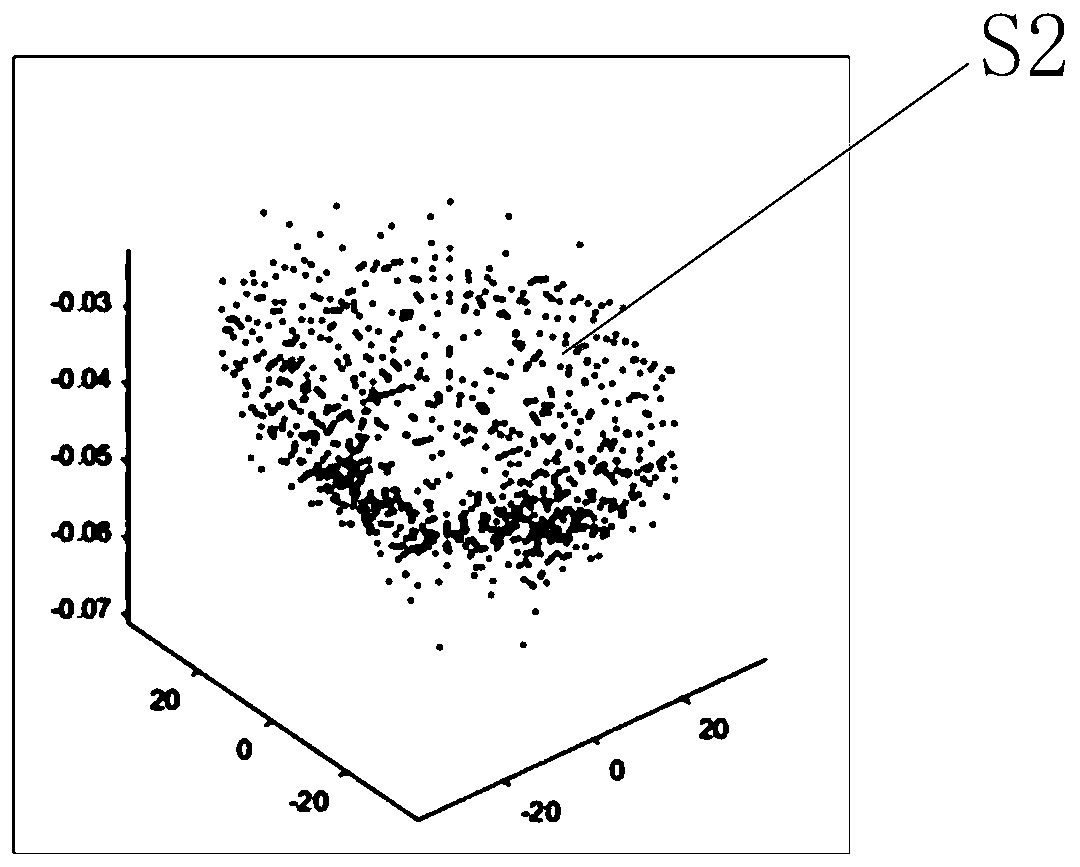

[0038] Step 1. Select the two discs processed by turning and milling as the parts to be assembled, use a three-coordinate measuring machine to measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com