Device and method for improving polarization-maintaining optical fiber polarization coupling measurement precision and symmetry

A technology for coupling measurement and polarization-maintaining fibers, which is used in measurement devices, testing optical properties, instruments, etc., and can solve the problems of envelope broadening and interference peak drop, affecting measurement accuracy, and reducing the spatial resolution of polarization mode coupling. Simple, effective, effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

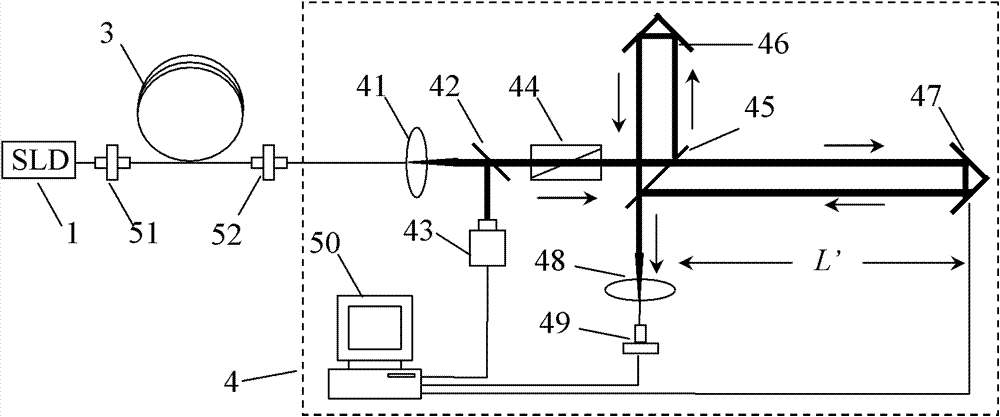

specific Embodiment approach 1

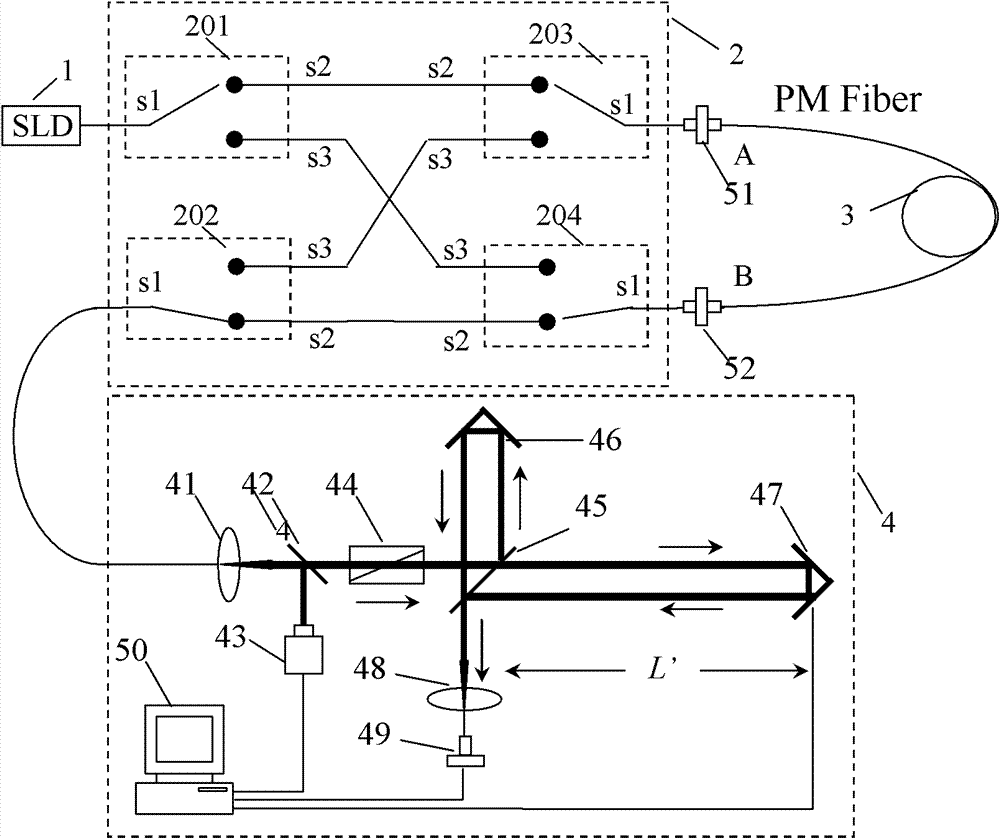

[0037] like figure 2 shown. The optical signal controllable reversing mechanism 2 is composed of four 1×2 polarization-maintaining optical switches to realize cross transposition of light. The common terminals s1 of the polarization maintaining switches 201 and 202 are respectively connected to the broadband light source 1 and the polarization coupling detection system 4, and the common terminals s1 of the polarization maintaining switches 203 and 204 are connected to the front end A of the optical fiber 3 to be tested through the rotary connectors 51 and 52 respectively. It is connected to the rear end B; the constant terminals s2 of the polarization maintaining switches 201-204 are connected to each other, and the action terminals s3 are cross-connected. Without loss of generality, if it is required to measure the polarization coupling of polarization-maintaining fiber at 1550nm wavelength, the wide-spectrum light source should be SLD, the fiber output power is about 5mW, ...

specific Embodiment approach 2

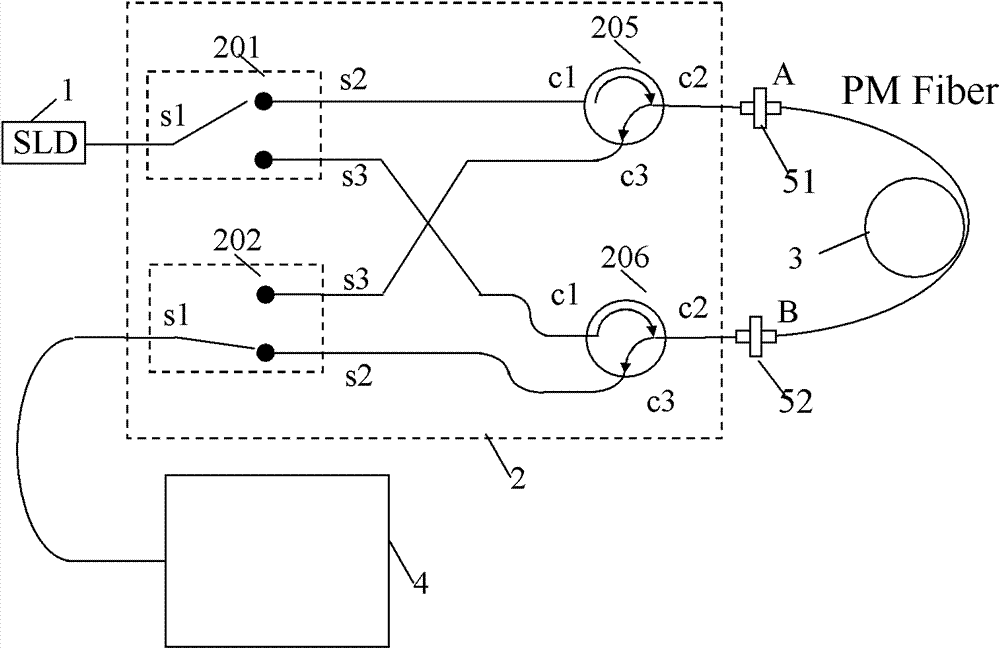

[0039] like image 3 shown. The composition of optical signal controllable reversing mechanism 2 can also be figure 2 The two 1×2 fiber optic switches in replace the three-port fiber optic circulator.

[0040] like image 3 shown. The optical signal controllable reversing mechanism 2 is composed of four 1×2 polarization-maintaining optical switches to realize cross transposition of light. The common terminals s1 of the polarization maintaining switches 201 and 202 are respectively connected to the broadband light source 1 and the polarization coupling detection system 4, and the output terminals c2 of the three-port circulators 205 and 206 are respectively connected to the front end A and the rear end B of the optical fiber 3 to be tested; The normally connected terminal s2 and the operating terminal s3 of the polarization maintaining switch 201 are respectively connected to the input terminals c1 of the circulators 205 and 206, and the normally connected terminal s2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com