Method for analyzing and measuring silver content in chromium bronze alloy

A measurement method, the technology of chromium bronze, applied in the field of chemical detection, can solve the problems that cannot meet the requirements of chromium bronze alloy, etc., and achieve the effect of easy operation and high accuracy of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

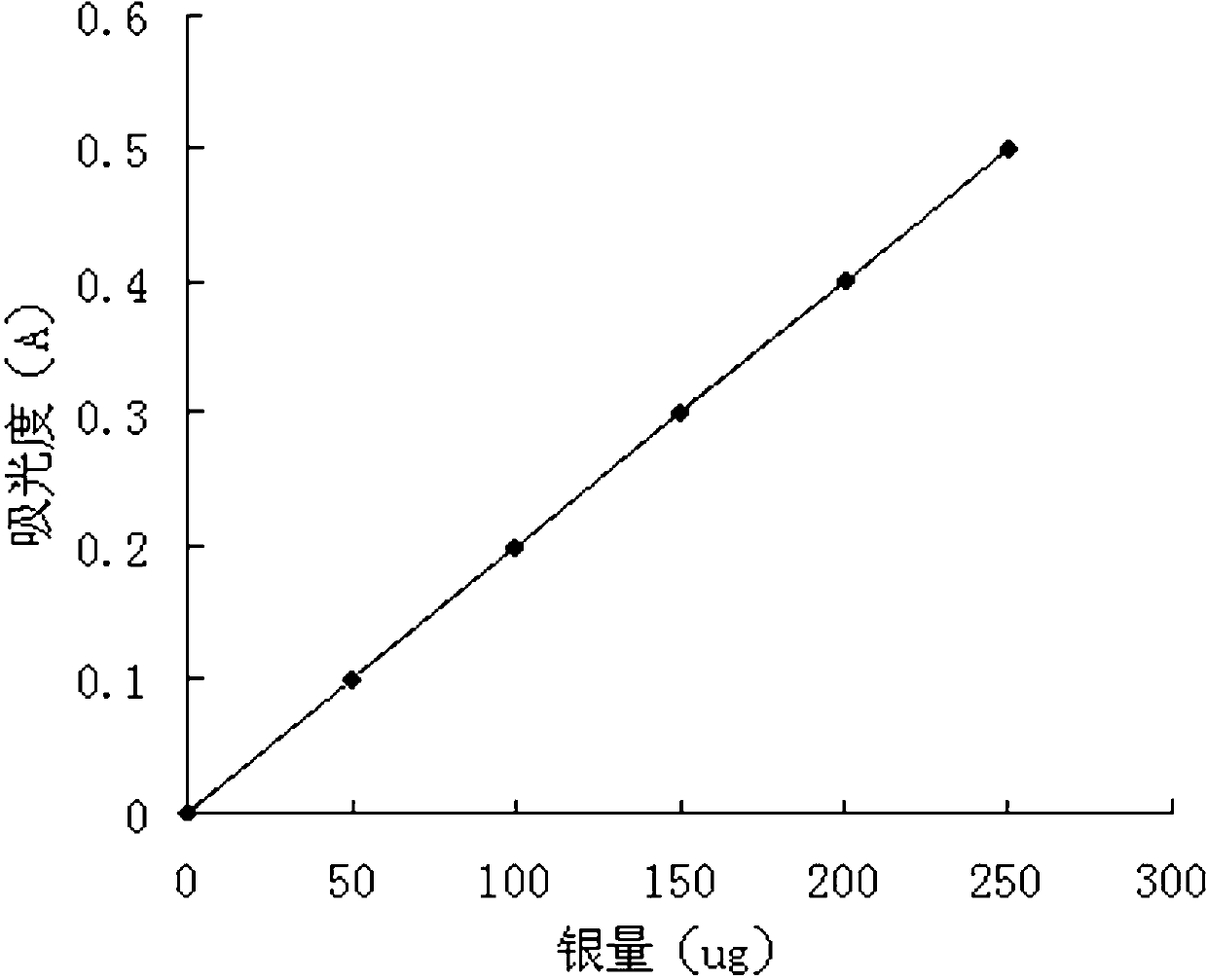

Image

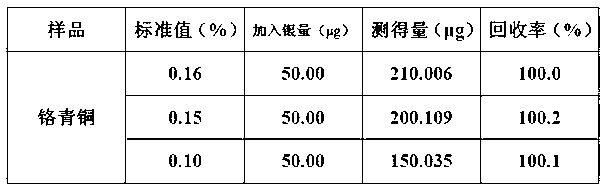

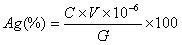

Examples

Embodiment

[0062] Weigh 10.0000g of pure copper, the weight percentage of silver in the pure copper is less than 0.0010%, put it in a 500mL beaker, add 50mL of nitric acid solution (1+3), heat to dissolve the pure copper, boil to remove nitrogen oxides in the solution , cooled, transferred to a 200mL volumetric flask, diluted with water to the mark, and mixed to obtain a copper solution, containing 50mg of copper per milliliter of the copper solution;

[0063] Weigh 0.5656g of dried potassium dichromate reference reagent, put it in a 250mL beaker, dissolve it in water, add 5mL of sulfuric acid with a density of 1.84g / mL, after cooling, add dropwise a 30% hydrogen peroxide solution, and place it until When the yellow color disappears, transfer it to a 1000mL volumetric flask, dilute to the mark with water, and mix well to obtain a chromium solution, which contains 200μg chromium per milliliter;

[0064] Weigh 0.1228g of cerium oxide, put it in a 300mL beaker, then add 10mL of water, 5mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com