Graphene-based piezoresistive pressure sensor and preparation method thereof

A pressure sensor, graphene-based technology, applied in the measurement of fluid pressure by changing ohmic resistance, measurement of the property force of piezoresistive materials, instruments, etc., can solve the problem that the thickness uniformity and consistency of piezoresistive films cannot be guaranteed , high bonding temperature of silicon glass, increased process complexity, etc., to achieve broad market application value and prospects, good piezoresistive properties, and maintain the effect of structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] One embodiment of the present invention proposes a kind of preparation method of graphene-based piezoresistive pressure sensor, it comprises:

[0053] Prepare a graphene film on a metal substrate to form a metal / graphene film;

[0054] Coating PMMA on the surface of the graphene film to form metal / graphene film / PMMA;

[0055] The graphene film coated with PMMA on the metal substrate is subjected to bubbling and peeling by electrochemical method to obtain graphene film / PMMA;

[0056] Transfer the graphene film / PMMA to SiO 2 / Si substrate, PMMA is removed to obtain graphene film / SiO 2 / Si;

[0057] The graphene film / SiO 2 / Si transfer to SiC substrate;

[0058] For the SiO 2 / Si substrate for etching;

[0059] Patterning the graphene film;

[0060] A metal electrode is vapor-deposited on the graphene film to obtain a graphene-based piezoresistive pressure sensor.

[0061] In an embodiment of the present invention, the graphene film that is coated with PMMA on the...

Embodiment

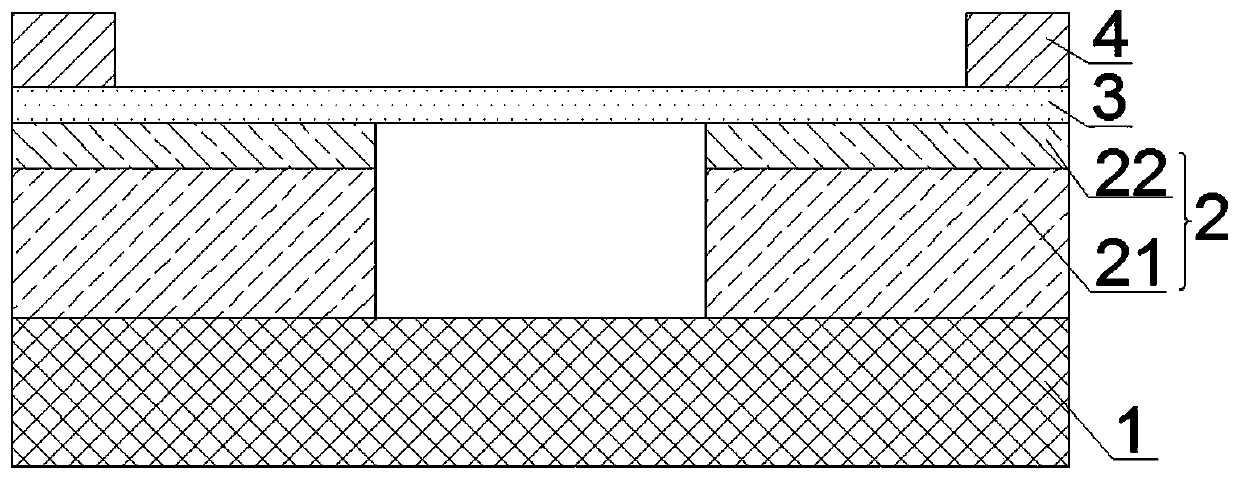

[0101] like figure 1 As shown, a graphene-based piezoresistive pressure sensor includes a silicon carbide substrate 1, a silicon dioxide / silicon intermediate layer 2 (including a silicon layer 21, a silicon dioxide layer 22), a graphene film sensitive layer 3 and Gold metal electrodes4.

[0102] The preparation method of the graphene-based piezoresistive pressure sensor specifically comprises the following steps:

[0103] (1) Deposit and prepare graphene film on high-precision double-light rolled copper foil by PECVD method, wherein the thickness of copper foil is 25 μm, the frequency of plasma pulse power supply is 50 kHz, the reaction temperature is 600 ° C, and the reaction time is 1 h. The graphene film is single-layer graphene;

[0104](2) Spin-coat PMMA (polymethyl methacrylate) on the gained copper base / graphene film with a homogenizer; wherein the rotating speed of the homogenizer is 3000rpm, and the PMMA thickness is 5 μm;

[0105] (3) bubbling and stripping the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com