Graphene oxide enhanced dispersed copper-tungsten-chromium electric contact material and preparation method thereof

An electrical contact material and graphene technology are applied in the field of graphene oxide reinforced disperse copper tungsten-chromium electrical contact materials and their preparation, which can solve the problems of poor affinity and interface bonding force, prone to agglomeration and the like, and achieve good wetting. performance, optimized bonding interface, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of graphene oxide reinforced dispersed copper tungsten chromium electrical contact material includes the following steps:

[0037] (1) Ingredients

[0038] According to the mass percentage, weigh 56.5-57% Cu-0.4wt.% Al alloy powder, 35% W powder, 5% Cr powder, 0.1-0.5% graphene oxide and 2.5-3.4% Cu 2 O powder, spare;

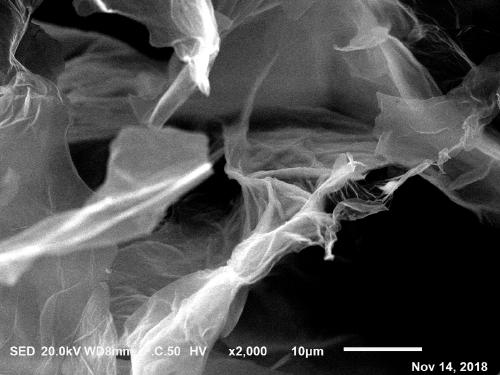

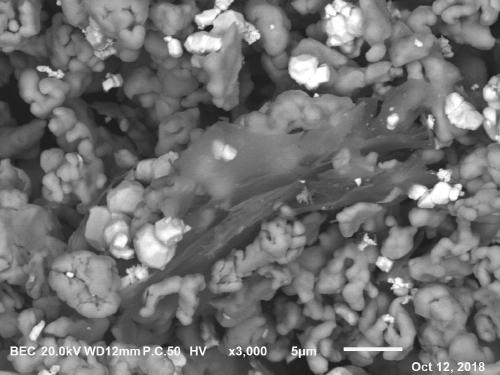

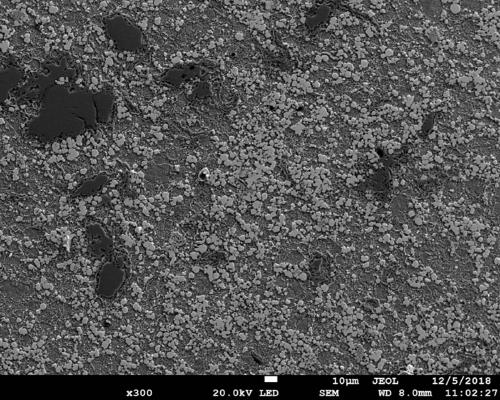

[0039] Among them, Cu-0.4wt% Al alloy powder has a particle size of 38 μm, tungsten powder has a particle size of 2-5 μm, chromium powder has a particle size of 44 μm, and Cu 2 The particle size of the O powder is 2-5μm, the graphene oxide is a single-layer graphene oxide, the sheet diameter is 0.5-5μm, and the thickness is 0.8-1.2 nm. Weigh each raw material (the calculation method for weighing is the volume of the part×theoretical density×the ratio of addition). The raw material ratio of graphene oxide / dispersed copper tungsten chromium electrical contact material is shown in Table 1 below.

[0040] Composite material compositionCu-...

Embodiment 1

[0054] The preparation size is Ø50×10 mm, 0.1GO / Al doped with 0.1% graphene oxide 2 O 3 -Cu / (35)W(5)Cr electrical contact material.

[0055] The specific preparation method is:

[0056] Step 1, ingredients

[0057] Calculate the respective amounts of copper-aluminum alloy powder, cuprous oxide powder, tungsten powder, and chromium powder in proportion, the amount of copper-aluminum alloy powder=part volume×theoretical density×addition ratio=19.63 cm 3 ×10.53 g / cm 3 ×57.05%=117.92g, tungsten powder=part volume×theoretical density×addition ratio=19.63 cm 3 ×10.53 g / cm 3 ×35%=72.35g, chromium powder=part volume×theoretical density×addition ratio=19.63 cm 3 ×10.53 g / cm 3 ×5%=10.34g, cuprous oxide powder=part volume×theoretical density×addition ratio=19.63 cm 3 ×10.53 g / cm 3 ×2.85%=5.89g, the amount of graphene oxide=part volume×theoretical density×addition ratio=19.63cm 3 ×10.53 g / cm 3 ×0.1%=0.21g.

[0058] Step 2. Mix

[0059] Mix the copper-aluminum alloy powder, tungsten powder, chromium...

Embodiment 2

[0070] The preparation size is Ø50×10 mm, 0.3GO / Al doped with 0.3% graphene oxide 2 O 3 -Cu / (35)W(5)Cr electrical contact material.

[0071] The specific preparation method is:

[0072] Step 1, ingredients

[0073] Calculate the respective amounts of copper-aluminum alloy powder, cuprous oxide powder, tungsten powder, and chromium powder in proportion, the amount of copper-aluminum alloy powder=part volume×theoretical density×addition ratio=19.63cm 3 ×10.46g / cm 3 ×56.85%=116.73g, tungsten powder=part volume×theoretical density×addition ratio=19.63cm 3 ×10.46g / cm 3 ×35%=71.87g, chromium powder=part volume×theoretical density×addition ratio=19.63cm 3 ×10.46g / cm 3 ×5%=10.27g, cuprous oxide powder=part volume×theoretical density×addition ratio 19.63cm 3 ×10.46g / cm 3 ×2.84%=5.83g, the amount of graphene oxide=part volume×theoretical density×addition ratio=19.63cm 3 ×10.46g / cm 3 ×0.3%=0.62g.

[0074] Step 2. Mix

[0075] Mix the copper-aluminum alloy powder, tungsten powder, chromium powder a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com