A method for suppressing the production of sulfur trioxide in flue gas from heavy non-ferrous metal smelting acid production

A non-ferrous metal, sulfur trioxide technology, applied in chemical instruments and methods, separation methods, non-metallic elements, etc., can solve the problems of insignificant actual effect, large consumption of hydrogen sulfide, inappropriate sulfur trioxide, etc., to avoid Catalytic oxidation, low cost, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

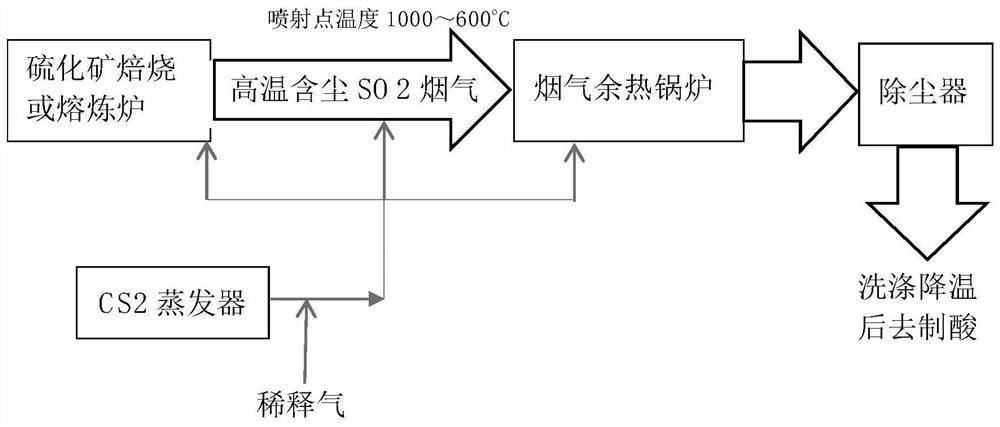

[0029] A method for suppressing the production of sulfur trioxide in the flue gas of heavy nonferrous metal smelting acid production, aiming at the high concentration of SO produced by the combustion of nonferrous metal sulfide ores in smelting or roasting furnaces 2 Flue gas, using CS 2 Inject the flue gas for the reducing agent to suppress SO at an appropriate temperature 3 The method of producing and converting part of the heavy metal components into easy-to-remove sulfides.

[0030] The temperature of the flue gas at the tail of the roasting furnace is 800-1200°C, and then go through the basic treatment procedures such as waste heat boiler, cyclone dust collector, electrostatic precipitator, washing and cooling, and flue gas acid production.

[0031] Liquid CS 2 After being vaporized by the heating evaporator, dilute it with nitrogen or water vapor to a concentration of 1-10%, and spray it into a suitable flue section with a gas nozzle under a certain pressure.

[0032]...

Embodiment 2

[0039] A copper smelting flue gas, the waste heat boiler outlet flue gas volume is 70000Nm 3 / h, inlet temperature 1100±100℃, outlet temperature 350±30℃, flue gas SO at the outlet of electrostatic precipitator 2 Concentration is 10%, SO 3 The concentration is 0.5%, and the waste heat boiler is an integral type. In the flue and boiler before entering the waste heat boiler, 7 nozzles are installed at the position where the flue gas temperature is 700 ° C, and 10% CS is configured. 2 gas, using N 2 Injected into the flue as a carrier gas, the injection volume is 1400m 3 / h, SO in the flue gas at the outlet of the electrostatic precipitator 3 600ppm.

Embodiment 3

[0041] A lead smelting flue gas volume is 60000Nm 3 / h, the flue gas first flows out of the tail of the roaster with a temperature of 900-1100 ° C, the outlet temperature is 320-380 ° C, and then passes through the waste heat boiler, cyclone dust collector and electric dust collector in sequence, and finally undergoes washing and cooling and flue gas acid production. .

[0042] Liquid CS 2 After gasification, the N 2 Dilute it as a diluent gas to a volume concentration of 10%, and finally spray it into the flue section with a temperature of 800°C before the inlet of the waste heat boiler, and mix it with flue gas to suppress the production of sulfur trioxide. Using single-stage injection, a total of 6 injection points are evenly arranged on the flue section according to the principle of equal area division, and the injection volume is 960m 3 / h.

[0043] Without spraying CS 2 When, the electrostatic precipitator outlet SO 2 Concentration is 8%, SO 3 Concentration of 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com