Metal-metal nitride laminated coating resistant to high temperature marine environment corrosion and preparation method thereof

A marine environment, multi-layer coating technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve problems such as high-temperature corrosion of titanium alloys, achieve good bonding strength, simple preparation process, and high temperature resistance The effect of excellent corrosion performance in marine environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

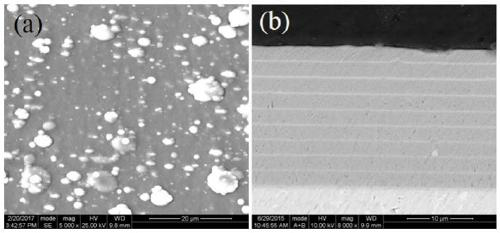

[0052] In this embodiment, the metal / metal nitride multilayer coating resistant to high temperature marine environment corrosion is formed by alternately depositing Ti sub-layers and TiN sub-layers on the Ti6Al4V substrate, and the layers near the substrate and the uppermost layer are TiN layers. The thickness of the TiN sublayer is 2.0 μm, the thickness of each Ti sublayer is 0.1 μm, and the total number of layers is 17.

[0053] The preparation method of the above-mentioned metal / metal nitride multi-layer coating resistant to high temperature marine environment corrosion specifically includes the following steps:

[0054] (1) Cleaning of the substrate

[0055] First, after grinding and polishing the Ti6Al4V titanium alloy (Ti-6%Al-4%V, mass fraction) substrate, put it into a solution mixed with acetone and ethanol at a volume ratio of 1:2, and use 15-20kHz ultrasonic cleaning for 10- After 15 minutes, take it out and dry it; then use ion plating equipment to carry out ion b...

Embodiment 2

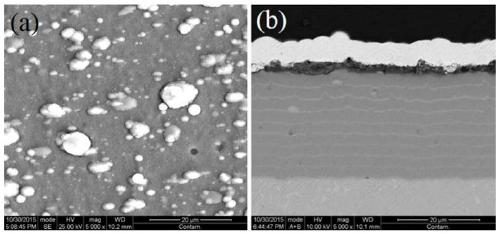

[0060] In this embodiment, the metal / metal nitride multilayer coating resistant to high temperature marine environment corrosion is formed by alternately depositing Ti sub-layers and TiN sub-layers on the Ti6Al4V substrate, and the layers near the substrate and the uppermost layer are TiN layers. The thickness of the TiN sublayer is 2.0 μm, the thickness of each Ti sublayer is 0.2 μm, and the total number of layers is 15 layers.

[0061] The preparation method of the above-mentioned metal / metal nitride multi-layer coating resistant to high temperature marine environment corrosion specifically includes the following steps:

[0062] (1) Cleaning of the substrate

[0063] First, after grinding and polishing the Ti6Al4V titanium alloy (Ti-6%Al-4%V, mass fraction) substrate, put it into a solution mixed with acetone and ethanol at a volume ratio of 1:2.5, and use 15~20kHz ultrasonic cleaning for 10~ After 15 minutes, take it out and dry it; then use the ion plating equipment to ca...

Embodiment 3

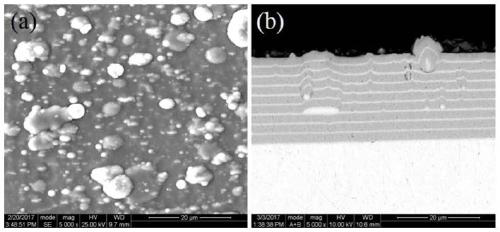

[0068] In this embodiment, the metal / metal nitride multilayer coating resistant to high temperature marine environment corrosion is formed by alternately depositing Ti sub-layers and TiN sub-layers on the Ti6Al4V substrate, and the layers near the substrate and the uppermost layer are TiN layers. The thickness of the TiN sublayer is 1.9 μm, the thickness of each Ti sublayer is 0.3 μm, and the total number of layers is 15 layers.

[0069] The preparation method of the above-mentioned metal / metal nitride multi-layer coating resistant to high temperature marine environment corrosion specifically includes the following steps:

[0070] (1) Cleaning of the substrate

[0071] First, after grinding and polishing the Ti6Al4V titanium alloy (Ti-6%Al-4%V, mass fraction) substrate, put it into a solution mixed with acetone and ethanol at a volume ratio of 1:3, and use 15~20kHz ultrasonic cleaning for 10~ After 15 minutes, take it out and dry it; then use ion plating equipment to carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com