A kind of preparation method of ultra-coarse tungsten carbide cemented carbide containing trace amount of cobalt

A cemented carbide and trace technology, used in the field of high hardness cemented carbide to prepare high strength, can solve the problems of fracture toughness and hardness contradiction, achieve uniform composition, reduce pores, and improve overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

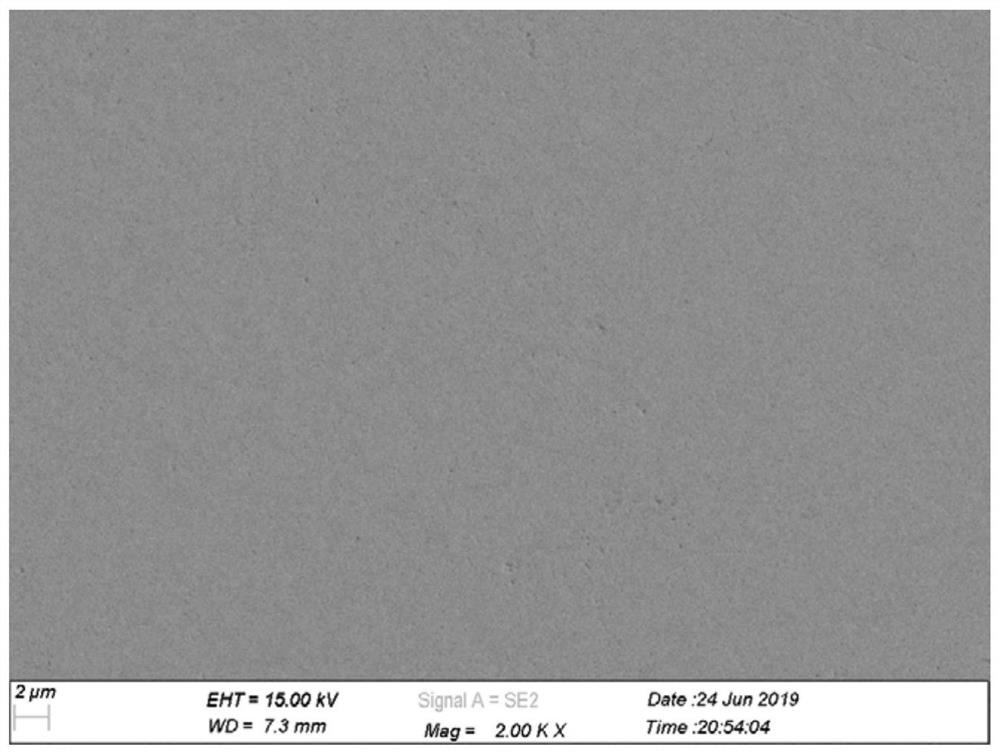

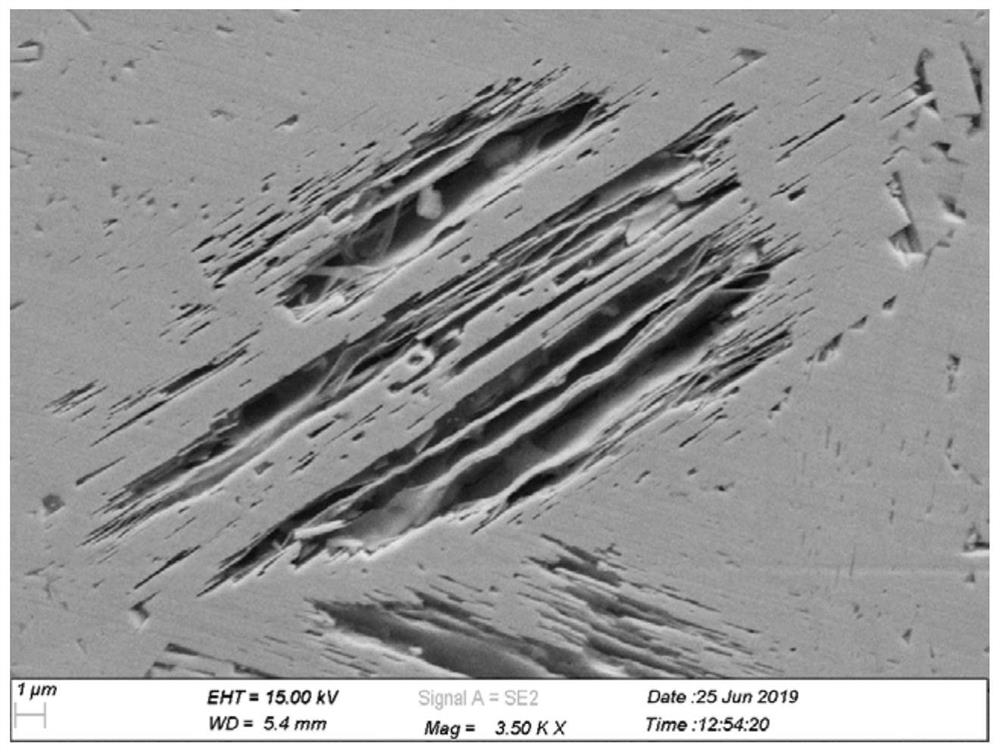

Image

Examples

Embodiment 1

[0030] The ultra-coarse WC cemented carbide composite material of the present embodiment is carried out as follows:

[0031] 1. Select WC powder with a particle size of 20 μm, nano WC-6Co composite powder with a grain size ≤ 200 nm, and cobalt powder with an average particle size of 3 μm. According to the composition of the required WC cemented carbide, weigh coarse-grained WC powder and nano-WC-6Co composite powder, the mass ratio of the two is 3:1, and add 4wt% Co, and use a mixer to mix mechanically for 2 hours to obtain a mixed Uniform cemented carbide mixture powder; according to the required product size, weigh a certain amount of composite powder;

[0032] 2. Fill the cemented carbide mixture powder weighed in step 1 into the graphite mold covered with graphite paper; use a manual hydraulic press to pre-press the graphite mold filled with the composite powder, and the pressure is ~10MPa;

[0033] 3. Wrap ~5mm thick carbon felt on the periphery of the graphite mold fill...

Embodiment 2

[0040] The ultra-coarse WC cemented carbide composite material of the present embodiment is carried out as follows:

[0041] 1. Select WC powder with a particle size of 20 μm, nano WC-6Co composite powder with a grain size ≤ 200 nm, and cobalt powder with an average particle size of 3 μm. According to the composition of the required WC cemented carbide, weigh coarse-grained WC powder and nano-WC-6Co composite powder, the mass ratio of the two is 3:1, and add 4wt% Co, and use a mixer to mix mechanically for 2 hours to obtain a mixed Uniform cemented carbide mixture powder; according to the required product size, weigh a certain amount of composite powder;

[0042] 2. Fill the cemented carbide mixture powder weighed in step 1 into the graphite mold covered with graphite paper; use a manual hydraulic press to pre-press the graphite mold filled with the composite powder, and the pressure is ~10MPa;

[0043] 3. Wrap ~5mm thick carbon felt on the periphery of the graphite mold fill...

Embodiment 3

[0050] The ultra-coarse WC cemented carbide composite material of the present embodiment is carried out as follows:

[0051] 1. Select WC powder with a particle size of 20 μm, nano WC-6Co composite powder with a grain size ≤ 200 nm, and cobalt powder with an average particle size of 3 μm. According to the composition of the required WC cemented carbide, weigh coarse-grained WC powder and nano-WC-6Co composite powder, the mass ratio of the two is 3:1, and add 4wt% Co, and use a mixer to mix mechanically for 2 hours to obtain a mixed Uniform cemented carbide mixture powder; according to the required product size, weigh a certain amount of composite powder;

[0052] 2. Fill the cemented carbide mixture powder weighed in step 1 into the graphite mold covered with graphite paper; use a manual hydraulic press to pre-press the graphite mold filled with the composite powder, and the pressure is ~10MPa;

[0053] 3. Wrap ~5mm thick carbon felt on the periphery of the graphite mold fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com