Automatic control method for separation and purification of ginsenoside Rd

A technology for the separation and purification of ginsenosides, which is applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems that restrict the scientific research of ginsenoside monomers and the clinical application of medicine, and achieve improved repeatability, The effect of increasing economic value and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

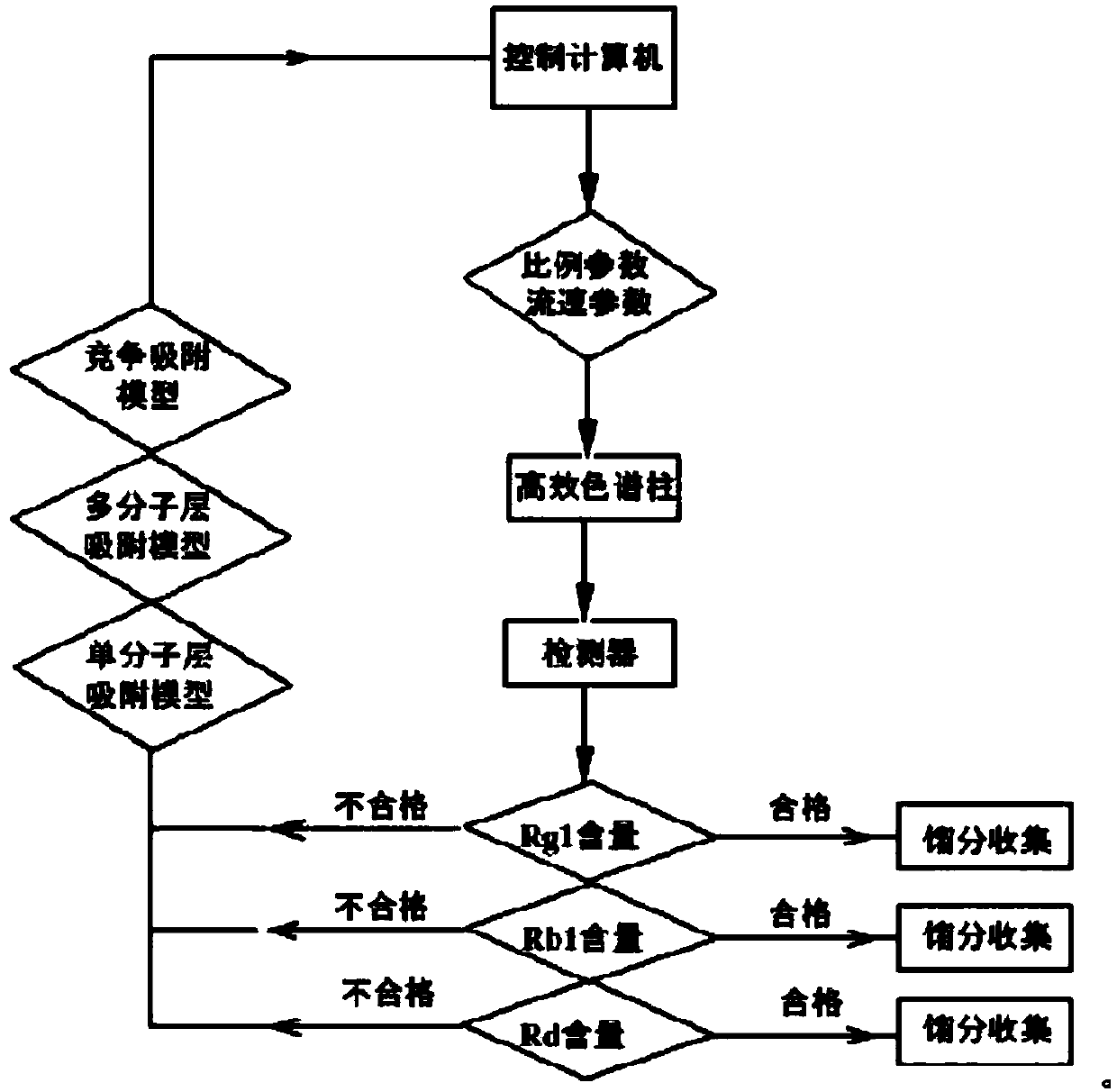

Method used

Image

Examples

Embodiment 1

[0140] Adopt reverse-phase high-efficiency chromatographic column separation and purification of ginsenoside extract, 80mL of sample solution (containing ginsenoside extract 80g, wherein, Rg1 content is 10%, Rb1 content is 9%, Rd content is 22%, raw material spectrogram is as follows image 3Shown, wherein, Rg1 peak time is 34.9min, Rb1 peak time is 44.5min, Rd peak time is 53.1min), the eluting solvent is ethanol / water, the ratio of the volume sum of ethanol and ethanol and water is (10~60): 100 (the volume ratio of ethanol and water is increasing in real time, gradient elution), the elution flow rate is 120mL / min, and the chromatographic column used is a reversed-phase high performance liquid chromatography column, which is a dynamic axial compression column, The inner diameter is 50mm and the height is 600mm. The filler is spherical ODS filler with a particle size of 10 microns. The column is packed by wet method. The actual number of separation plates is 12000; the flow rat...

Embodiment 2

[0149] (1) Set the elution parameters according to the chromatographic column used and the target content of saponins Rg1, Rb1, and Rd in the ginsenoside to be eluted;

[0150] The chromatographic column used is a reverse-phase high-performance liquid chromatography column, which is a dynamic axial compression column with an inner diameter of 50 mm and a height of 600 mm. The filler is a spherical ODS filler with a particle size of 10 microns. The column is packed in a wet method. The actual number of separation plates is 12000;

[0151] Elution sample: 80mL of sample solution (containing ginsenoside extract 80g, Rg1 content is 10%, Rb1 content is 9%, Rd content is 22%), and it is loaded into the chromatographic column;

[0152] The elution target is that the content of ginsenoside Rg1 is higher than 40%, or the content of Rb1 is higher than 40%, or the content of ginsenoside Rd is higher than 80%;

[0153] The elution parameters were set as the elution solvent was a mixture ...

Embodiment 3

[0164] (1) Set the elution parameters according to the chromatographic column used and the target content of each saponin Rg1, Rb1, and Rd in the ginsenoside to be eluted;

[0165] The chromatographic column used is a reverse-phase high-performance liquid chromatography column, which is a dynamic axial compression column with an inner diameter of 50 mm and a height of 600 mm. The filler is a spherical ODS filler with a particle size of 10 microns. The column is packed in a wet method. The actual number of separation plates is 12000;

[0166] Elution sample: 80mL of sample solution (containing ginsenoside extract 80g, Rg1 content is 11%, Rb1 content is 8%, Rd content is 21%), and it is loaded into the chromatographic column;

[0167] The elution target is that the content of ginsenoside Rg1 is higher than 40%, or the content of ginsenoside Rb1 is higher than 40%, or the content of ginsenoside Rd is higher than 80%.

[0168] Set the elution parameters as the elution solvent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com