Method used for combined treatment of copper slag and magnesium slag, and applications thereof

A combined treatment and magnesium slag technology, applied in the field of metallurgy, can solve the problems of low technological innovation ability, less than 1% copper slag iron utilization rate, high pollution, etc., to eliminate the problem of volume stability, eliminate poor volume stability, overcome active lower effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

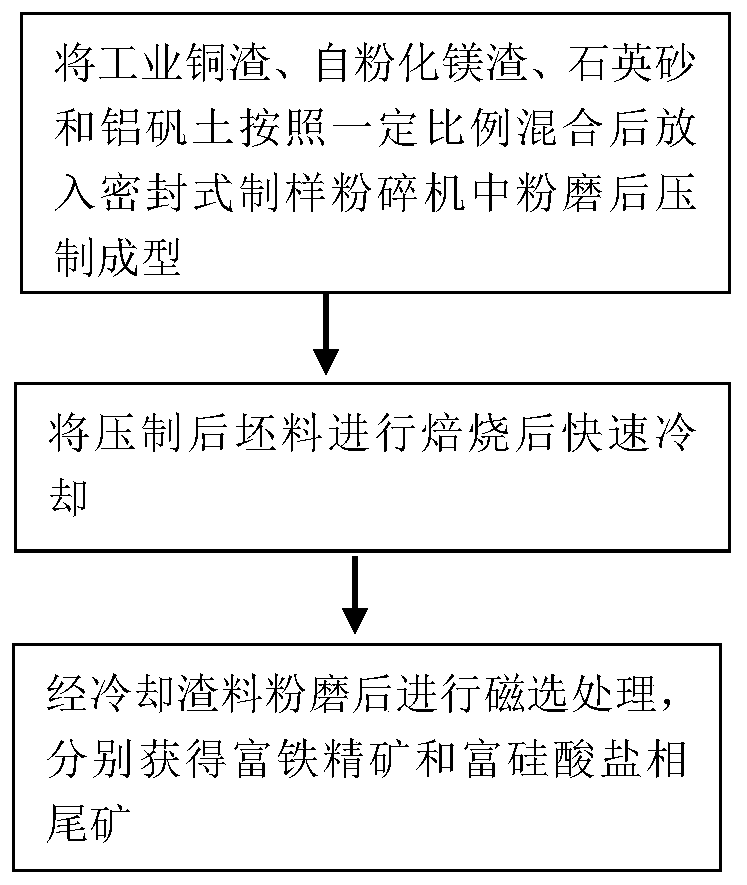

[0052] A kind of method of joint treatment copper slag and magnesium slag of the present embodiment, described method specifically comprises the following steps:

[0053] (1) Taking the smelting slow cooling copper slag of a copper smelter as raw material, its chemical composition (mass ratio %) measured by XRF is shown in Table 1.

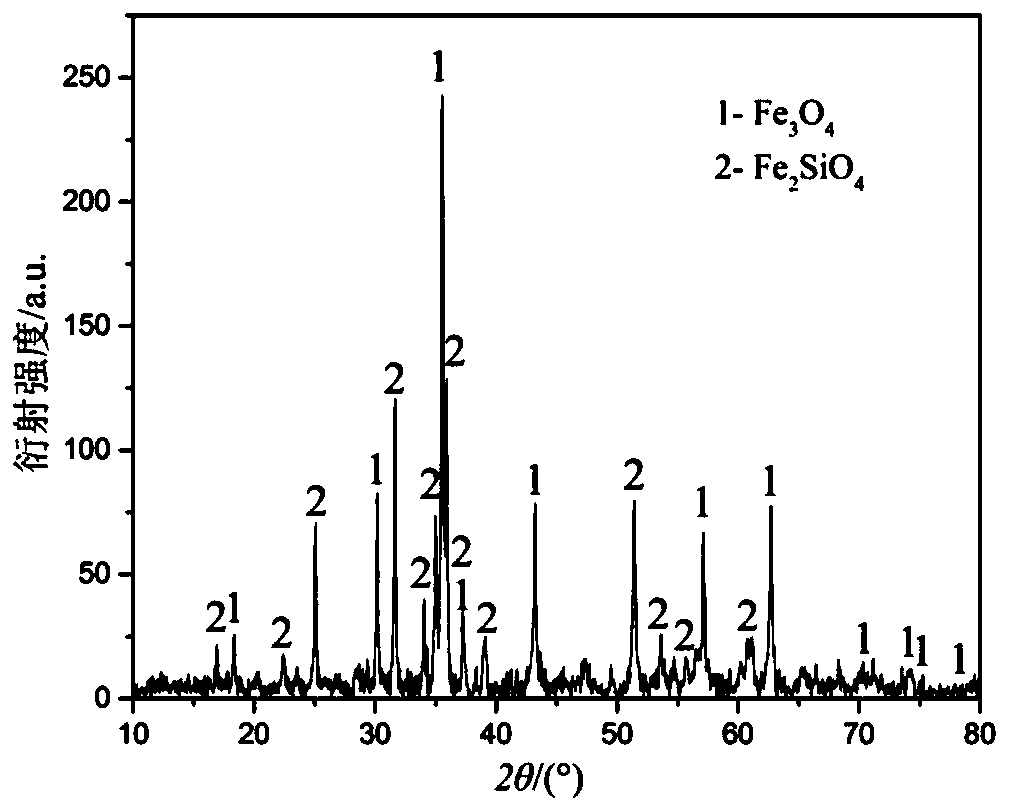

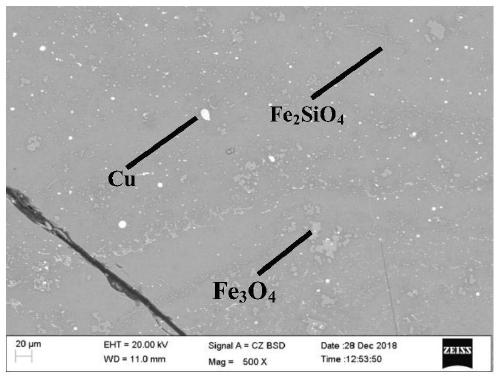

[0054] (2) Put the industrial copper slag into the vibration mill and grind for 2 minutes, and control the particle size of the copper slag to be less than 200 mesh. Then the industrial copper slag after grinding and the self-powdering magnesium slag (its chemical composition (mass ratio %) is shown in Table 2) are put into the sealed sample preparation pulverizer after mixing according to the mass ratio of 62.5:100 Grind to below 200 mesh. The ground and mixed raw materials are pressed into cakes. Put the pressed sample into a high-temperature muffle furnace and raise the temperature to 1200°C and keep it warm for 2 hours, then take out the sam...

Embodiment 2

[0063] A kind of method of joint treatment copper slag and magnesium slag of the present embodiment, described method specifically comprises the following steps:

[0064] After grinding, industrial copper slag (composition is the same as in Example 1, and the particle size is less than 200 meshes), self-powdering magnesium slag (composition is the same as in Example 1), quartz sand and bauxite are in a mass ratio of 70:100:10:5 After mixing, put it into a sealed sample preparation grinder and grind it again to below 200 mesh. The ground and mixed raw materials are pressed into cakes. Put the pressed sample into a high-temperature muffle furnace and raise the temperature to 1200°C and keep it warm for 2 hours, then take out the sample and cool it with compressed air. After cooling, the mixed slag is ground by a vibration mill for 2 minutes and then subjected to magnetic separation. The magnetic separation method is wet weak magnetic separation, the magnetic separation current ...

Embodiment 3

[0069] A kind of method of joint treatment copper slag and magnesium slag of the present embodiment, described method specifically comprises the following steps:

[0070] After grinding, industrial copper slag (composition is the same as in Example 1, and the particle size is less than 200 meshes), self-powdering magnesium slag (composition is the same as in Example 1), quartz sand and bauxite are in a mass ratio of 80:100:10:5 After mixing, put it into a sealed sample preparation grinder and grind it again to below 200 mesh. The ground and mixed raw materials are pressed into cakes. Put the pressed sample into a high-temperature muffle furnace and raise the temperature to 1200°C and keep it warm for 2 hours, then take out the sample and cool it with compressed air. After cooling, the mixed slag is ground by a vibration mill for 2 minutes and then subjected to magnetic separation. The magnetic separation method is wet weak magnetic separation, the magnetic separation current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com