Preparation method of kaolin nanotubes

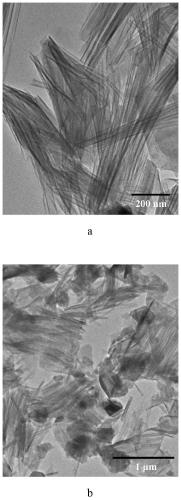

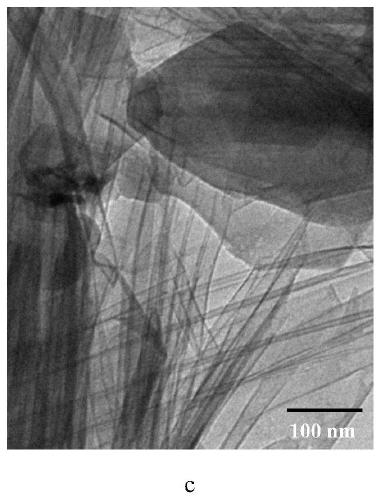

A technology of kaolin nanotubes and kaolin, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of cumbersome and complicated processes, low economic benefits, cumbersome processes, etc., and achieve simple and efficient processes , large economic value, and the effect of uniform pipe diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation method of this kaolin nanotube is as follows:

[0015] A. Select ordinary flaky kaolin as raw material, add 10g of kaolin into the intercalation agent N-methylformamide, prepare a slurry containing 1g of kaolin per milliliter of intercalation agent, and put it into a ball mill (Nanjing Boyuntong Instrument Technology Co., Ltd. , model: GB-80, the same below) in the ball mill for 1min, and dried to obtain powder.

[0016] B. Get 5g of the powder obtained in step A and mix it with 50mL of methanol, put it into a ball mill and mill it for 30min, and centrifuge to remove the solvent to obtain the kaolin grafted with methoxy on the surface;

[0017] C. Add 0.5 g of methoxy-grafted kaolin to 20 ml of methanol solution with a concentration of 1 mol / L cetyltrimethylammonium chloride, put it into a ball mill and mill it for 8 hours, and then wash it with ethanol into the washing liquid Add water until there is no foam, then dry, and heat up to 600°C for 5 hours ...

Embodiment 2

[0020] The preparation method of this kaolin nanotube is as follows:

[0021] A. Choose ordinary flaky kaolin as raw material, add 10g of kaolin to the intercalation agent pyridine, prepare a slurry containing 0.5g of kaolin per milliliter of intercalation agent, put it into a ball mill and mill for 10 minutes, and dry to obtain a powder. Ball mill manufacturer: Nanjing Boyuntong Instrument Technology Co., Ltd., model: GB-80;

[0022] B. Mix 5 g of the powder obtained in step A with 10 mL of ethanol, put it into a ball mill and mill it for 2 hours, and centrifuge to remove the solvent to obtain surface ethoxy grafted kaolin;

[0023] C. Add 1g of ethoxy-grafted kaolin to 20ml of methanol solution with a concentration of 1.2mol / L cetyltrimethylammonium bromide, put it into a ball mill and mill it for 24h, and then wash it with ethanol into the washing liquid Add water until there is no foam, then dry, and heat up to 600°C for 4 hours at a constant temperature at a heating rate...

Embodiment 3

[0026] The preparation method of this kaolin nanotube is as follows:

[0027] A. Choose ordinary flaky kaolin as raw material, add 10g of kaolin to the intercalation agent dimethyl sulfoxide, prepare a slurry containing 0.7g of kaolin per milliliter of intercalation agent, put it into a ball mill and mill for 1 hour, and dry to obtain a powder. Ball mill manufacturer: Nanjing Boyuntong Instrument Technology Co., Ltd., model: GB-80;

[0028] B. Get 5g of the powder obtained in step A and mix it with 20mL of methanol, put it into a ball mill and mill it for 10h, and centrifuge to remove the solvent to obtain surface methoxy grafted kaolin;

[0029] C. Add 0.5 g of methoxy-grafted kaolin to 20 ml of methanol solution with a concentration of 1.5 mol / L cetyltrimethylammonium chloride, put it into a ball mill and mill it for 18 hours, and then wash it with ethanol to the washing liquid Add water until there is no foam, then dry, heat up to 500°C at a constant temperature for 5 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com