High-speed jet impinging device and method of preparing two-dimensional nanomaterial with the same

An impact device, high-speed jet technology, applied in chemical instruments and methods, nano-carbon, bulk chemical production, etc., can solve the problems of low preparation efficiency, inability to scale up applications, etc., and achieve short preparation time, small structural damage, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

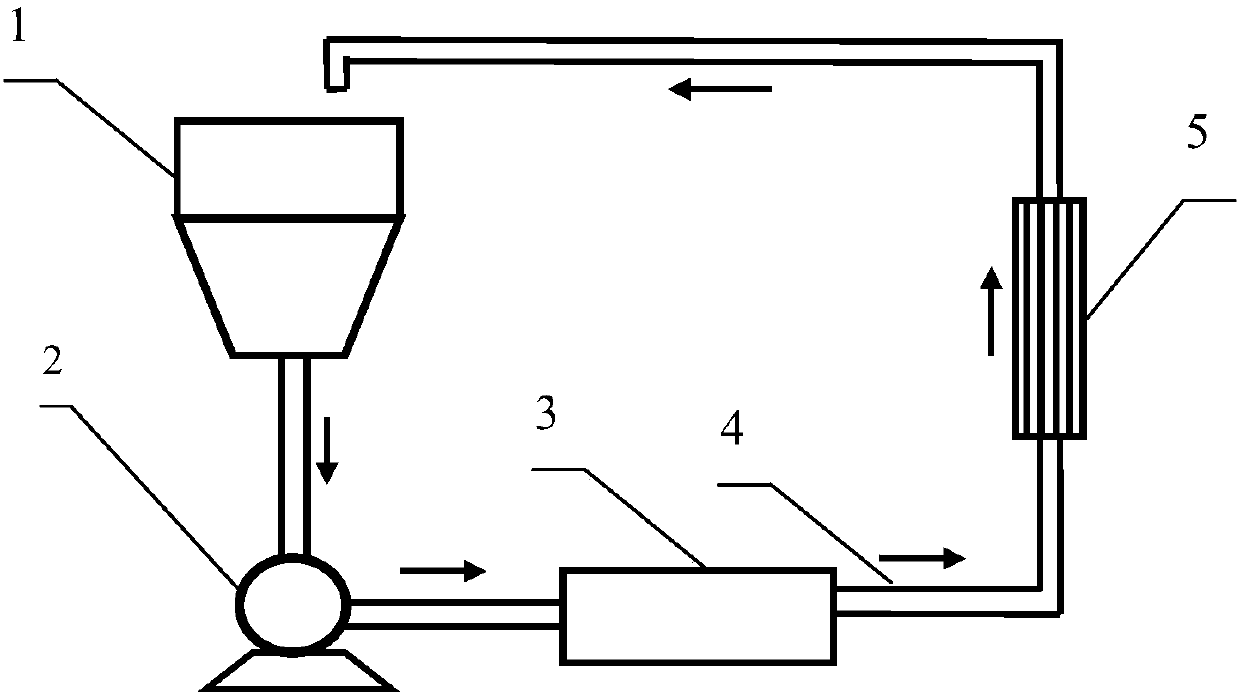

[0068] The high-speed jet impingement device of this embodiment is composed of a storage tank 1 , a high-pressure pump 2 , a jet impingement device 3 , a return pipeline 4 and a circulating cooling device 5 . Wherein, the outlet of the storage tank 1 is connected to the inlet of the high-pressure pump 2, the outlet of the high-pressure pump 2 is connected to the inlet of the jet impact device 3, and the outlet of the jet impact device 3 passes through the back flow The pipeline 4 is connected to the inlet of the storage tank 1 , and the circulating cooling device 5 is installed on the return pipeline 4 .

[0069] In this embodiment, the storage tank 1 is a V-shaped stainless steel barrel with a capacity of 1 cubic meter;

[0070] Described return pipeline 4 is the seamless stainless steel pipe that commercially available diameter is 24mm;

[0071] Described high-pressure pump 2 is the plunger pump that model is 3W60;

Embodiment 2

[0076] The high-speed jet impingement device of this embodiment is composed of a storage tank 1 , a high-pressure pump 2 , a jet impingement device 3 , a return pipeline 4 and a circulating cooling device 5 . Wherein, the outlet of the storage tank 1 is connected to the inlet of the high-pressure pump 2, the outlet of the high-pressure pump 2 is connected to the inlet of the jet impact device 3, and the outlet of the jet impact device 3 passes through the back flow The pipeline 4 is connected to the inlet of the storage tank 1 , and the circulating cooling device 5 is installed on the return pipeline 4 .

[0077] In this embodiment, the storage tank 1 is a V-shaped stainless steel barrel with a capacity of 2 cubic meters;

[0078] Described return pipeline 4 is the seamless stainless steel pipe that commercially available diameter is 30mm;

[0079] The high-pressure pump 2 is a reciprocating pump whose model is 3DP80;

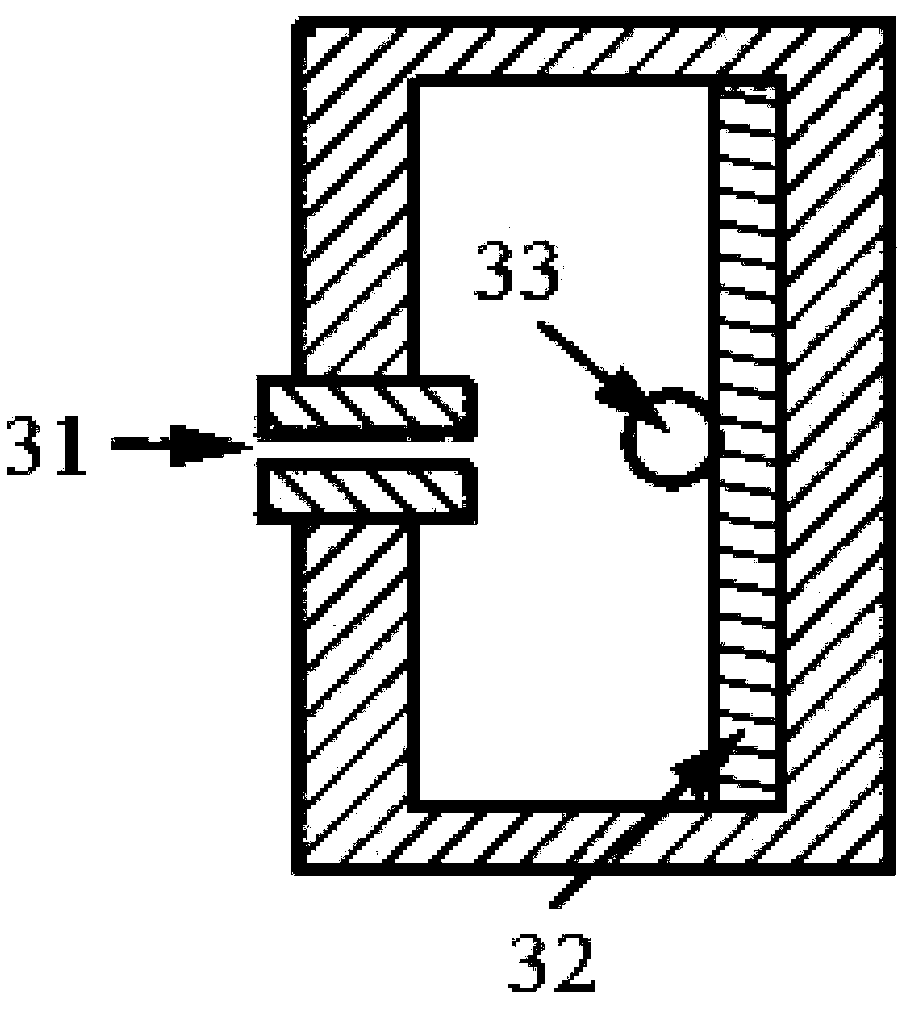

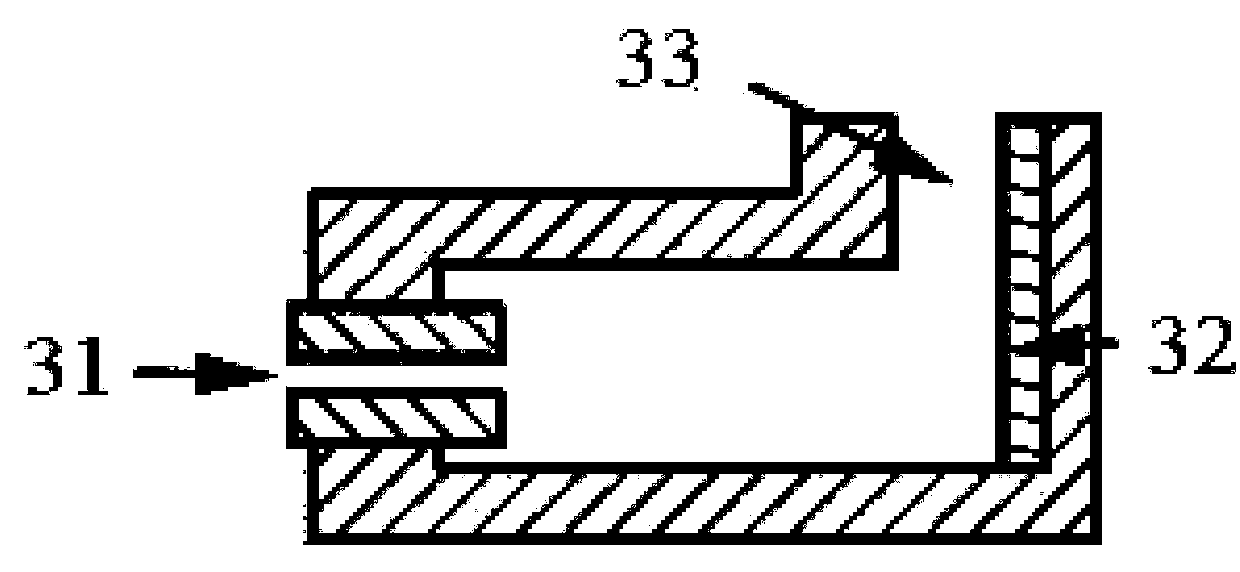

[0080] see Figure 7-8 , the jet impingement device is...

Embodiment 3

[0085] Utilize the device of embodiment 1 to prepare graphene nanoplate, may further comprise the steps:

[0086] Step 1: Add 325-mesh flake graphite powder into 10L of a mixed solution containing 50% by volume of isopropanol and water at a concentration of 5 mg / ml, stir evenly, and put it into storage tank 1;

[0087] Step 2: Using the high-pressure pump 2 to increase the pressure of the solution obtained in step 1 to about 40 MPa, and transport the solution to the target plate type jet impact device 3 for processing;

[0088] Step 3: The treated solution is returned to the storage tank 1 through the return line 4, and the pulverization step is repeated in the storage tank 1 for 3 hours. During this process, the temperature of the dispersion is maintained at about 25 degrees by the circulating cooling device 5;

[0089] Step 4: Repeat the above steps 1-3 for about 2 hours so that the thickness of the obtained graphene nanosheet is less than 100nm;

[0090] Step 5: After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com