Wind generating set blade lightning stroke protection system

A technology for wind turbines and lightning strike protection, applied to wind turbines, wind turbines in the same direction as the wind, engines, etc., can solve the problems of high efficiency of lightning strikes, small area of lightning strikes, frequent breakdown of down conductors, etc. , to achieve the effects of increasing the lightning strike area, reducing contact resistance, and reducing structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

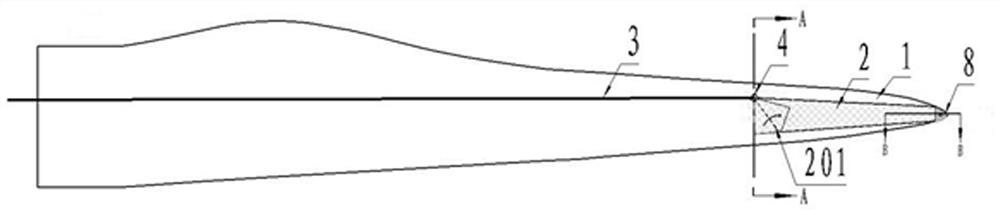

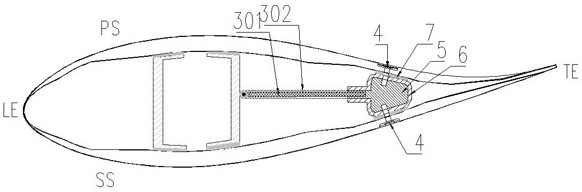

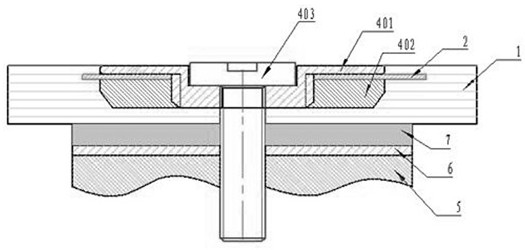

[0027] As shown in the figure, a lightning strike protection system for wind turbine blades includes a metal mesh 2 and a downconductor 3 connected by a metal mesh connection device 4, the metal mesh 2 is laid on the outer surface of the tip area of the blade shell 1 , the metal mesh 2 and the blade shell 1 are layered integrally laid and poured. And the metal mesh 2 is connected with the tip air-termination device 8 located at the tip of the blade; the downconductor 3 is arranged in other areas inside the blade other than the metal mesh, that is, there is no downconductor in the blade tip area, and the downconductor is 3 is arranged on the trailing edge side of the inner web of the blade, and the down conductor 3 includes an inner metal wire 301 and an outer insulating skin 302;

[0028] The metal mesh 2 is folded along the metal mesh folding line 201 at the end position biased towards the root. After the metal mesh 2 is folded, it is collected on the trailing edge side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com