Gradient material for guiding regeneration of periodontal hard and soft tissues and preparation method of gradient material

A gradient material and soft tissue technology, applied in tissue regeneration, spinning solution preparation, additive processing, etc., can solve the problems of religious restrictions on disease transmission, loss of ability to maintain space, etc., to avoid the risk of disease transmission, high cell affinity , high biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preferred embodiment of the present invention provides a method for preparing a gradient material to guide periodontal hard and soft tissue regeneration. The raw materials include: fish collagen from Sangon Biotechnology Co., Ltd., hexafluoroisopropanol from Aladdin Company, Shandong Jinan Daigang Biological Co., Ltd. The polylactic acid-glycolic acid of Technology Co., Ltd., the specific steps are as follows:

[0053] Step 1: Weigh 0.06g of nano-hydroxyapatite and disperse it in 2mL of hexafluoroisopropanol, and use an ultrasonic cell pulverizer to ultrasonically disperse for 1 hour;

[0054] Step 2: Weigh 0.02g fish collagen and add it to the dispersion obtained in step 1, shake it with a constant temperature oscillator for 10 minutes;

[0055] Step 3: Weigh 0.4g of polylactic acid-glycolic acid and add it to the mixed solution obtained in step 2, and shake it in a constant temperature oscillator at 25°C for 2 hours to obtain a spinning solution;

[0056] Step 4: U...

Embodiment 2

[0067] A preferred embodiment of the present invention provides a method for preparing a gradient material to guide periodontal hard and soft tissue regeneration. The raw materials include: fish collagen from Sangon Biotechnology Co., Ltd., hexafluoroisopropanol from Aladdin Company, Shandong Jinan Daigang Biological Co., Ltd. The polylactic acid-glycolic acid of Technology Co., Ltd., the specific steps are as follows:

[0068] Step 1: Weigh 0.06g of nano-hydroxyapatite and disperse it in 2mL of hexafluoroisopropanol, and use an ultrasonic cell pulverizer to ultrasonically disperse for 1 hour;

[0069] Step 2: Weigh 0.02g fish collagen and add it to the dispersion obtained in step 1, shake it with a constant temperature oscillator for 10 minutes;

[0070] Step 3: Weigh 0.4g of polylactic acid-glycolic acid and add it to the mixed solution obtained in step 2, and shake it in a constant temperature oscillator at 25°C for 2 hours to obtain a spinning solution;

[0071] Step 4: U...

experiment example 1

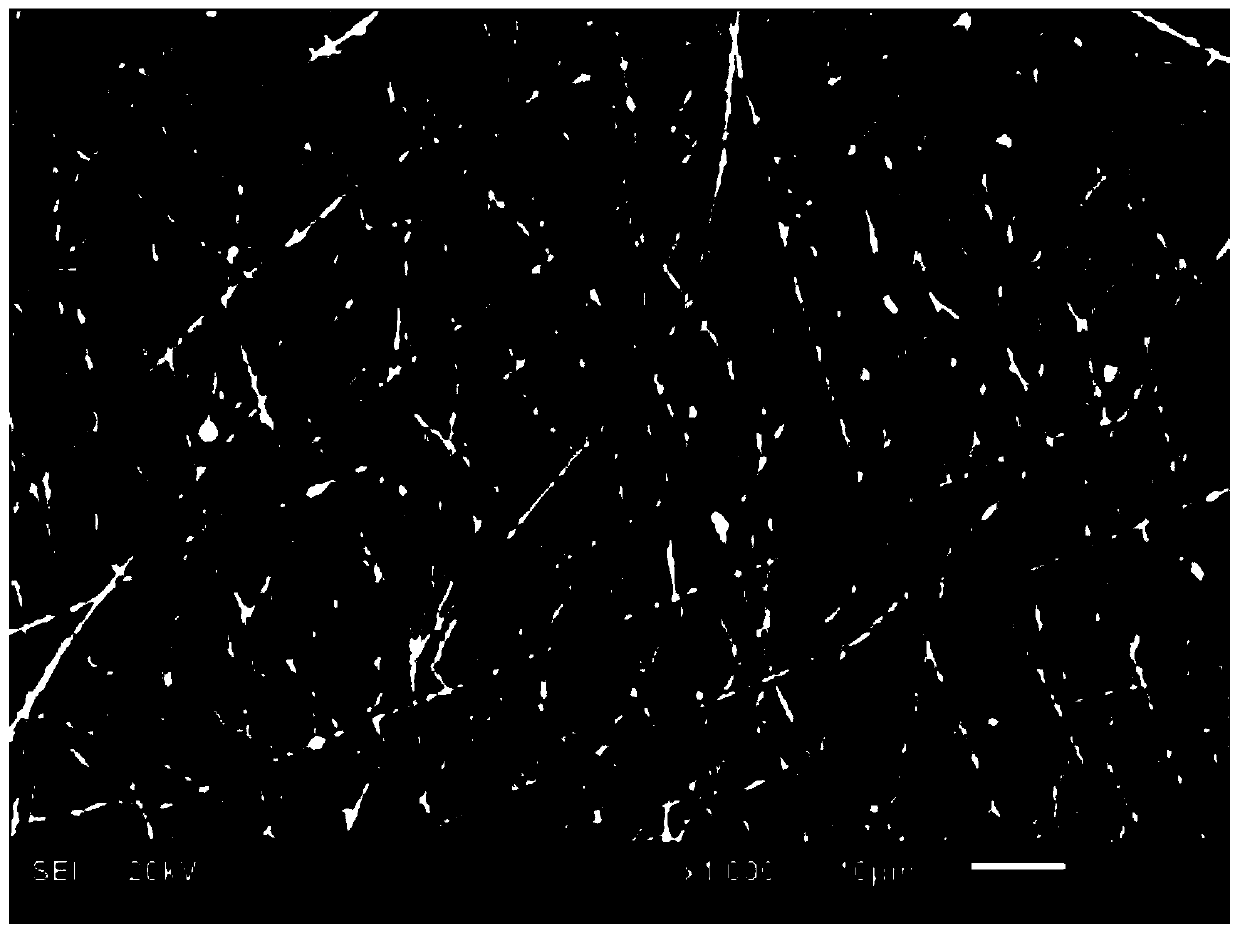

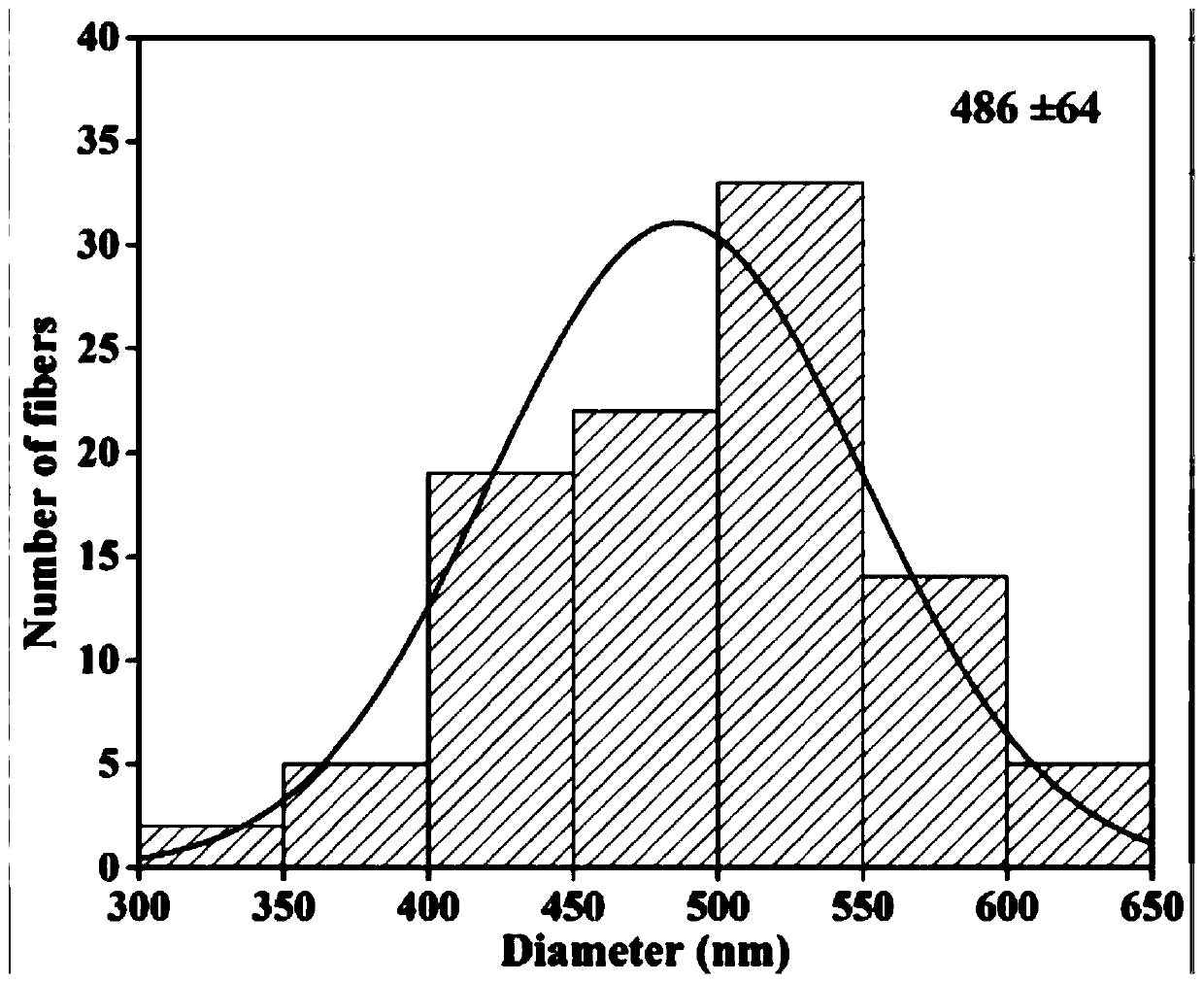

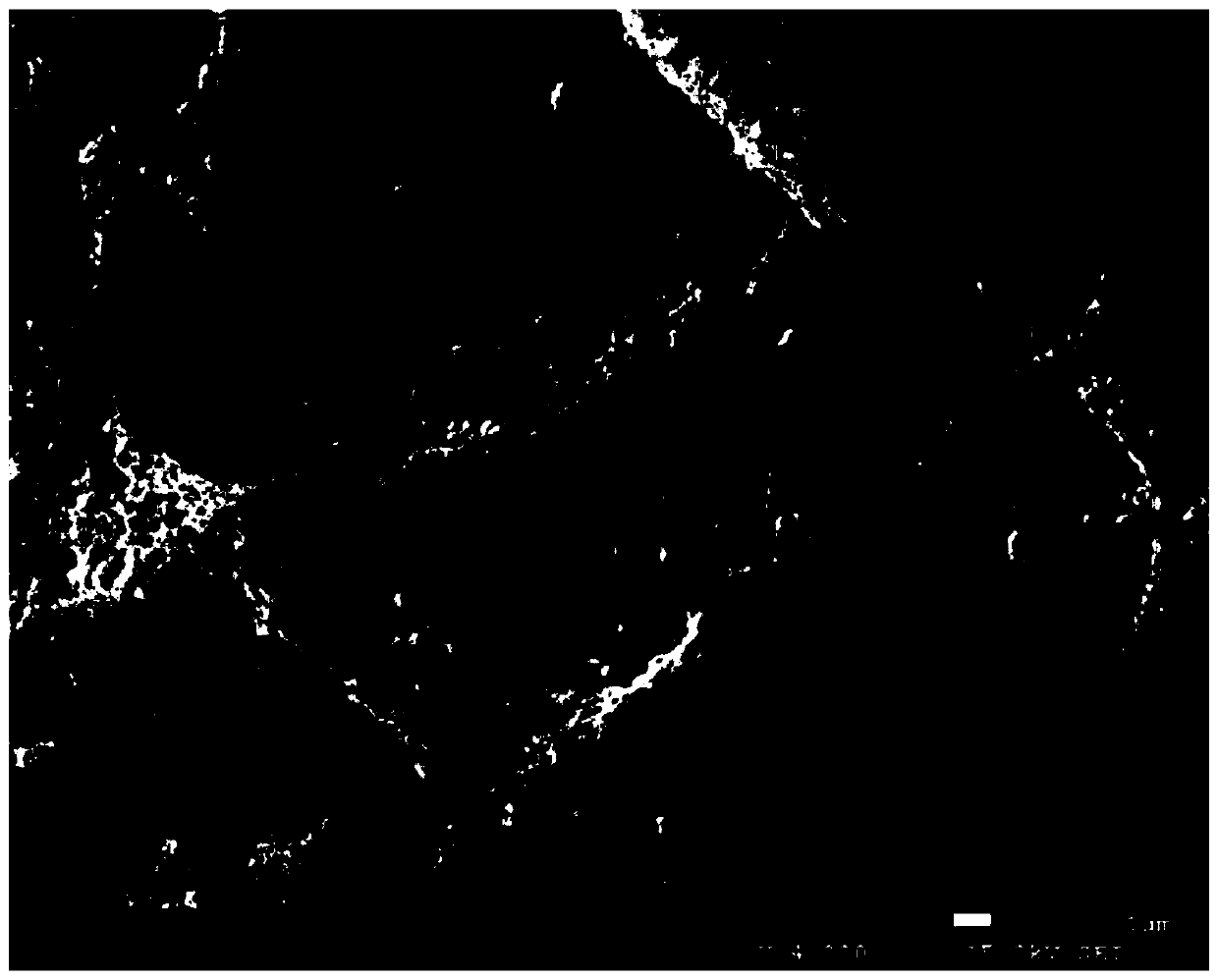

[0082] In the experiment, the composite fiber membrane of nano-hydroxyapatite / fish collagen / polylactic acid-glycolic acid was prepared by electrospinning method. The specific steps are as follows:

[0083] Step 1: Weigh 0.06g of nano-hydroxyapatite and disperse it in 2mL of hexafluoroisopropanol, and use an ultrasonic cell pulverizer to ultrasonically disperse for 1 hour;

[0084] Step 2: Weigh 0.02g fish collagen and add it to the dispersion obtained in step 1, shake it with a constant temperature oscillator for 10 minutes;

[0085] Step 3: Weigh 0.4g of polylactic acid-glycolic acid and add it to the mixed solution obtained in step 2, and shake it in a constant temperature oscillator at 25°C for 2 hours to obtain a spinning solution;

[0086] Step 4: Ultrasonically disperse the spinning solution obtained in Step 3 for 30 minutes again with an ultrasonic cell pulverizer;

[0087] Step 5: Prepare the nano-hydroxyapatite / fish collagen / polylactic acid-glycolic acid composite fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com