Microsphere coating device capable of timely chip removal

A coating device and technology for microspheres, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of uneven wall thickness of microspheres, spending a lot of time vacuuming, cracking, etc., to avoid The effect of coating overgrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

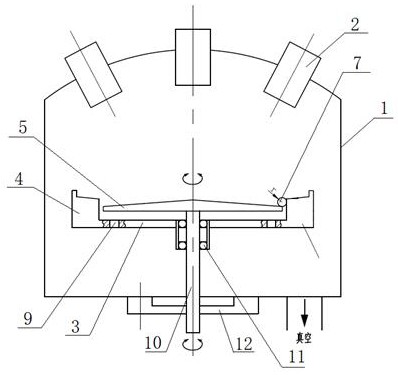

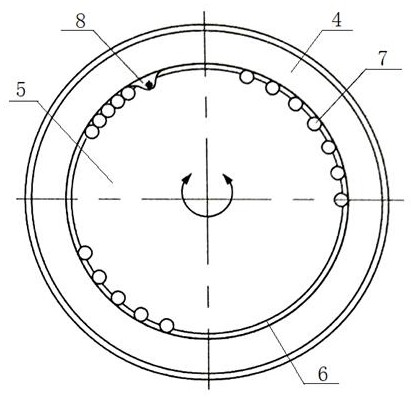

[0025] Embodiment 1: see figure 1 and figure 2 , a microsphere coating device capable of timely chip removal, comprising a vacuum chamber 1, a magnetron target gun 2 and a coating disk, the coating disk includes an outer cylinder and an inner turntable 5 arranged coaxially;

[0026] The outer cylinder is horizontally fixed in the vacuum chamber 1 and is composed of a bottom plate 3 and an annular body 4 on the bottom plate 3;

[0027] The inner turntable 5 is in the shape of a cone with a small top and a large bottom, and a magnetic coupler is provided at the bottom. The magnetic coupler is used to couple the motor outside the vacuum chamber 1 to drive the inner turntable 5 to rotate along the central axis of the inner turntable 5;

[0028] The bottom of the inner turntable 5 is not in contact with the bottom plate 3, and the edge of the inner turntable 5 is not in contact with the inner wall of the annular body 4 and forms an annular groove 6, the gap between which is small...

Embodiment 2

[0030] Embodiment 2: The inner wall of the annular body 4 above the inner turntable 5 is also provided with a paddle 8 for adjusting the posture of the microsphere 7, and the rest is the same as that of the embodiment 1. The purpose of the paddle 8 is to adjust the posture of the microsphere. When the microsphere rotates once a week, the posture will be adjusted once through the paddle 8, which is used to stimulate the random rotation of the microsphere 7, thereby avoiding the simple and periodic rotation in the prior art. The problem of uneven coating caused by rolling. When the present embodiment is working, it can be rotated in any mode, evenly, and with variable speed.

Embodiment 3

[0031] Embodiment 3: The inner wall of the annular body 4 above the inner turntable 5 is also provided with a paddle 8 for moving the microsphere 7 to adjust the attitude of the microsphere 7 , and the bottom plate 3 is provided with several chip discharge ports 9 . All the other are identical with embodiment 1. On the basis of Embodiment 1, the present invention adds a chip discharge port 9, so that the falling slag chips can not only enter the gap between the inner turntable 5 and the bottom plate 3, but also fall down through the chip discharge port 9 and enter the In vacuum chamber 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com