Liquid fermentation culture medium for high-yield antioxidant cordyceps sobolifera mycelium and production method of antioxidant cordyceps sobolifera mycelium granules

A liquid fermentation and mycelium technology, applied in the field of fermentation technology and micropowder technology production, can solve the problems of scarce wild resources, limited natural resources, long growth cycle, etc., and achieve high biomass, strong antioxidant activity and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

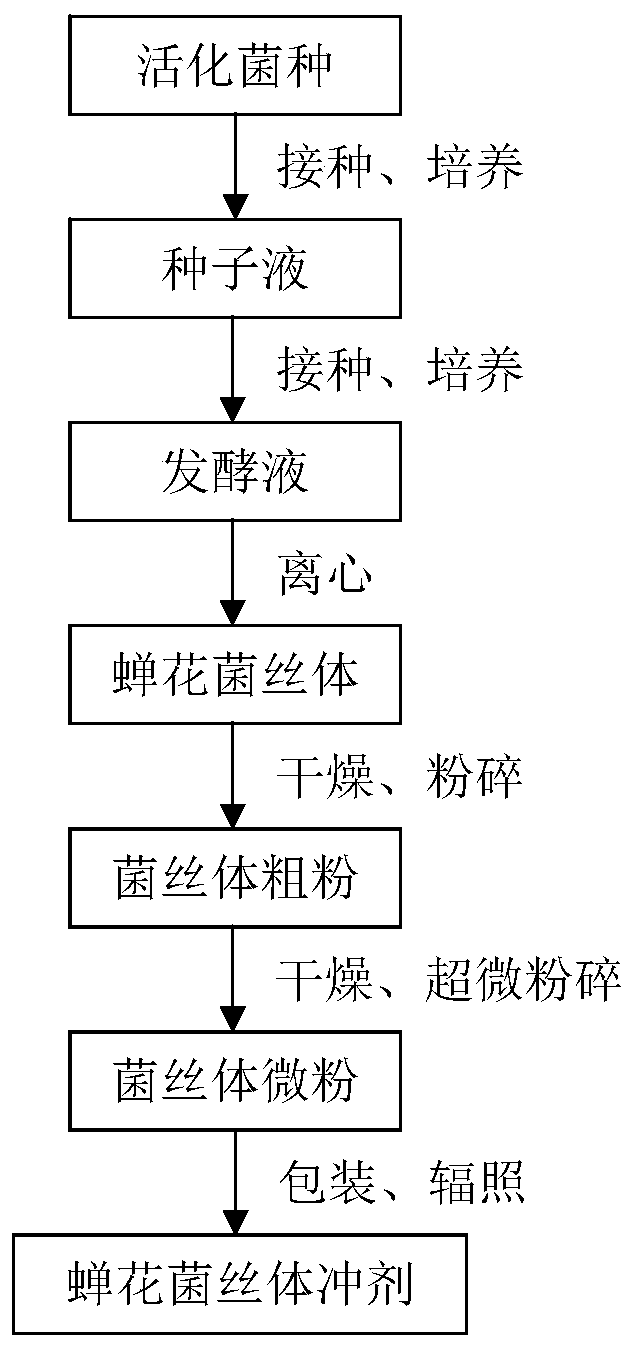

[0036] The production process of high-yield antioxidant cicada mycelium granule is as follows: figure 1 shown.

[0037] 1) Strain activation: Aseptically divide the Paecilomyces cicadae cultured on the slant into mung bean size, inoculate it on the PDA slant medium, and culture it at 25°C for 5 days;

[0038]2) Seed liquid preparation: the activated bacteria are aseptically divided into soybean grain size, inoculated into the seed culture liquid (mass fraction sucrose 2%, soluble starch 3%, soybean powder 2%, KH 2 PO 4 0.1%, MgSO 4 ·7H 2 O 0.05%, pH is natural, liquid content is 40%, add 3-5 glass beads to every 250mL Erlenmeyer flask), inoculate 4 pieces in each bottle, and culture at 25°C and 180r / min for 3 days to obtain the first-grade species . Inoculate the cultivated primary species into the same seed culture solution with a volume fraction of 10% aseptically, and cultivate the secondary species under the same conditions as the primary species;

[0039] 3) Prepar...

Embodiment 2

[0049] 1) Strain activation: Paecilomyces cicadae cultured on a slant was aseptically divided into mung bean size, inoculated on PDA slant medium, and cultured at 25° C. for 5 days.

[0050] 2) Preparation of seed liquid: aseptically divide the activated bacteria into soybean grain size, inoculate into seed culture liquid (2% sucrose, 3% soluble starch, 2% soybean powder, KH 2 PO 4 0.1%, MgSO 4 ·7H 2 O 0.05%, pH is natural, liquid content is 40%, add 3-5 glass beads to every 250mL Erlenmeyer flask), inoculate 8 pieces in each bottle, and culture at 25°C and 180r / min for 2 days to obtain the first-grade species ; Inoculate the cultured first-class species into the same seed culture solution with a volume fraction of 10% aseptically, and cultivate the second-class species under the same conditions as the first-class species;

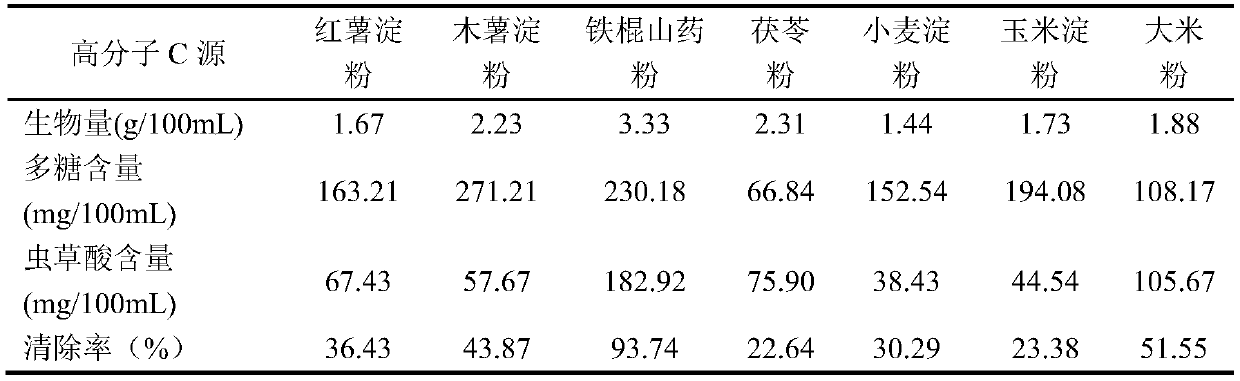

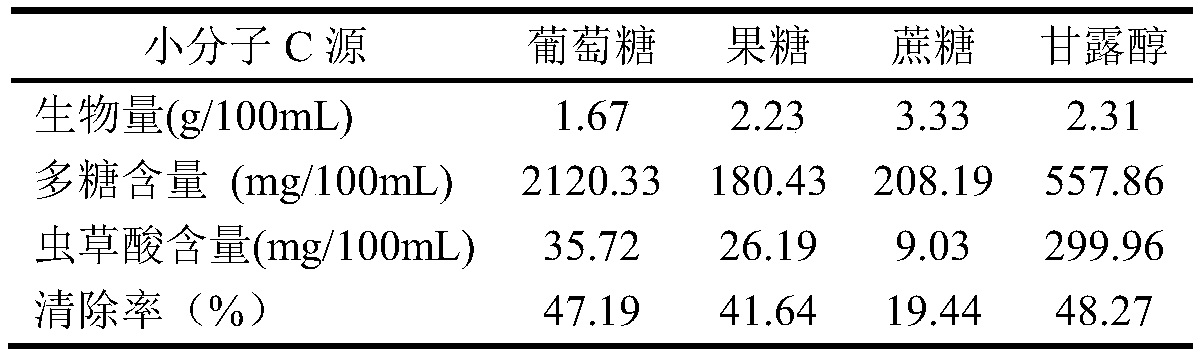

[0051] 3) Preparation of fermentation medium (take the preparation of 1000mL culture medium as an example): Weigh 50g of iron stick yam powder into a ...

Embodiment 3

[0061] 1) Strain activation: Aseptically divide the Paecilomyces cicadae cultured on the slant into mung bean size, inoculate it on the PDA slant medium, and culture it at 25°C for 5 days;

[0062] 2) Seed liquid preparation: the activated bacteria are aseptically divided into soybean grain size, inoculated into the seed culture liquid (mass fraction sucrose 2%, soluble starch 3%, soybean powder 2%, KH 2 PO 4 0.1%, MgSO 4 ·7H 2 O 0.05%, the pH is natural, the liquid content is 40%, add 3-5 glass beads to each 250mL Erlenmeyer flask), inoculate 3 pieces in each bottle, and culture at 25°C and 180r / min for 2 days to obtain the first-grade species . Inoculate the cultured primary species into the same seed culture solution with a volume fraction of 15% aseptically, and cultivate the secondary species under the same conditions as the primary species;

[0063] 3) Preparation of fermentation medium (take the preparation of 1000mL culture medium as an example): Weigh 10g of Tieg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com