Polymer electrolyte membrane, preparation method thereof and lithium ion battery

An electrolyte membrane and polymer technology, which is applied in the field of lithium-ion batteries, can solve the problems of easy aggregation, poor dispersion, and the impact on the electrical and safety performance of all-solid polymer electrolytes, and achieve appropriate flexibility, low crystallinity, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] A second aspect of the present invention provides a method for preparing a polymer electrolyte membrane, the method comprising:

[0056] (1) provide electrolyte slurry containing polymer fiber modified by the first silane coupling agent, crosslinkable copolymer, lithium salt, crosslinking agent, inorganic nanoparticles and photoinitiator; the first silane coupling The agent is a silane coupling agent containing a carbon-carbon unsaturated double bond;

[0057] (2) Casting the electrolyte slurry to obtain a semi-dry film, and then curing and crosslinking under ultraviolet light irradiation to form a polymer electrolyte membrane;

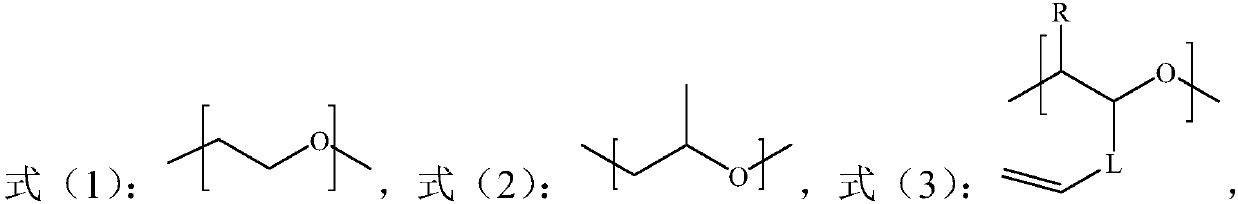

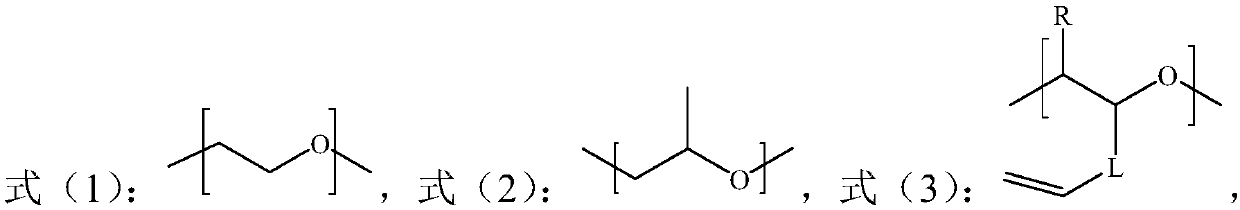

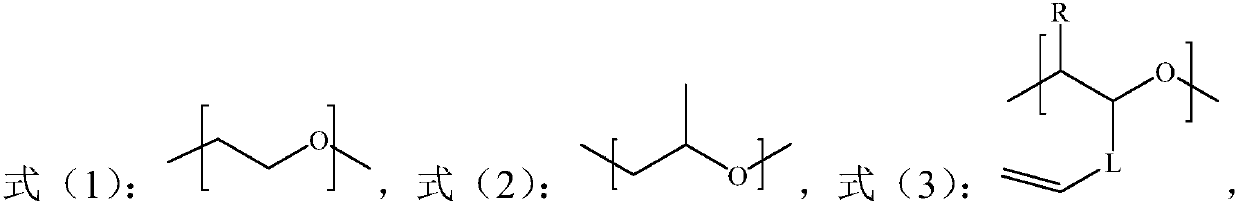

[0058] Wherein, the crosslinkable copolymer contains a structural unit represented by formula (1), a structural unit represented by formula (2) and an optional structural unit represented by formula (3),

[0059]

[0060] Wherein, R is H or C1-C4 alkyl, L is C0-C4 alkylene or -R 1 -O-R 2 -, R 1 C0-C4 alkylene, R 2 is C0-C4 alkylene;

...

preparation example 1

[0089] This preparation example is used to illustrate the inorganic nanoparticles modified by silane coupling agent.

[0090] TiO with a mass ratio of 1:2 2 Nanorods (diameter 150 nm, length 1 μm) and vinyltrimethoxysilane were added to ethanol (ethanol and TiO 2 The nanorods were used at a mass ratio of 5:1), then ultrasonically dispersed for 30 minutes, and reacted at 100° C. for 12 hours to obtain inorganic nanoparticles C1 modified by the silane coupling agent.

preparation example 2

[0092] This preparation example is used to illustrate the inorganic nanoparticles modified by silane coupling agent.

[0093] Nano Al 2 o 3 (purchased from Sumitomo Corporation, Japan, as particles with a particle size of 300nm) in hydrochloric acid (concentration is 0.1mol / L) to carry out surface treatment to make nano-Al 2 o 3 With hydroxyl groups on it, and then the surface-treated nano-Al according to the mass ratio of 1:3 2 o 3 with 3-methacryloxypropylethyldiethoxysilane added to isopropanol (isopropanol and nano-Al 2 o 3 The mass ratio is 4:1), followed by ultrasonic dispersion for 35 minutes, and reacted at 110° C. for 10 hours, so as to obtain the inorganic nanoparticles C2 modified by the silane coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com