A high-pressure hydrogen-doped natural gas environmental material performance damage evaluation device

A natural gas and environmental technology, which is applied in measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure. Probability of leakage, improved reliability and safety, effect of increased frequency of force application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

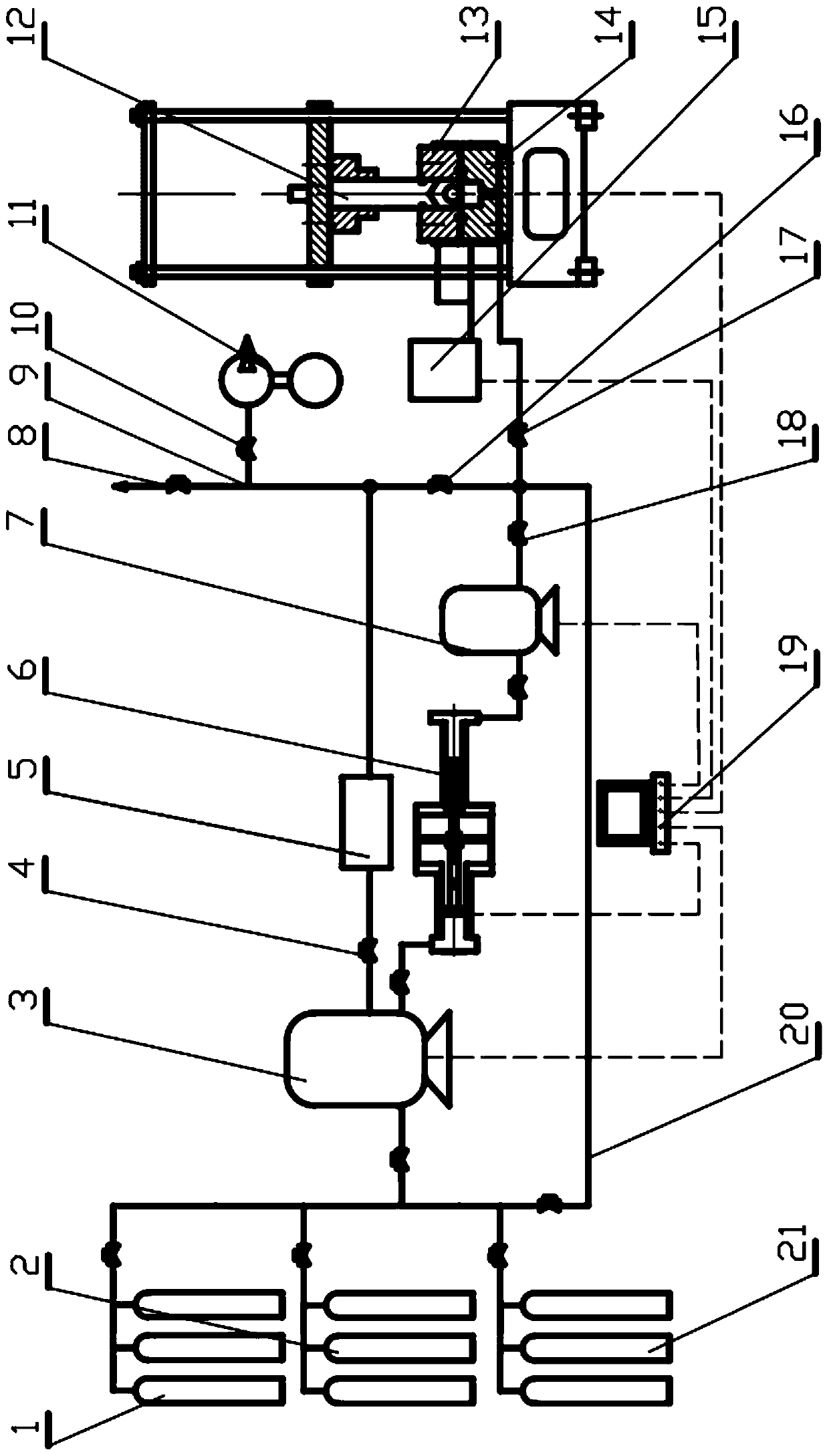

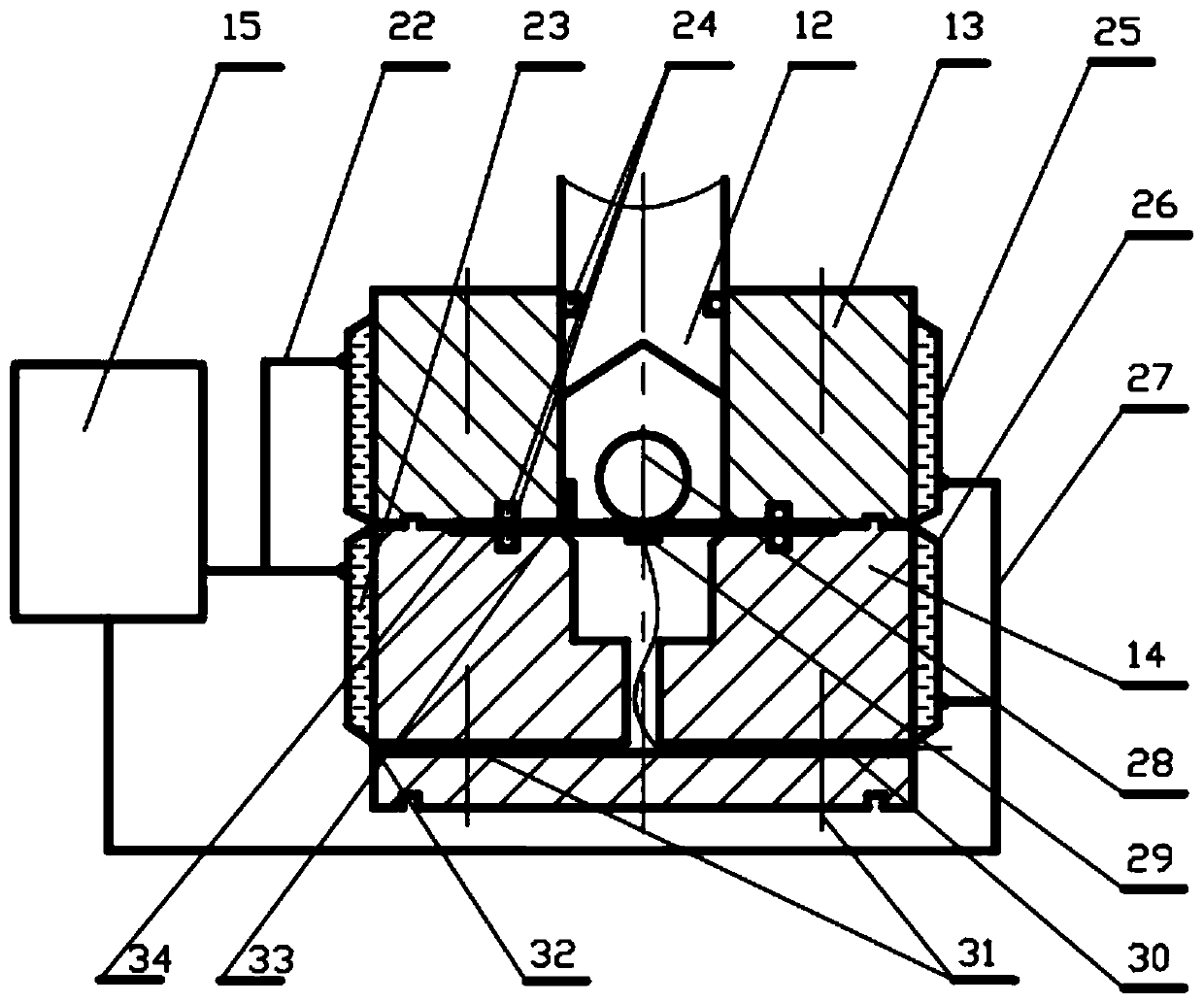

[0036] The performance damage evaluation device for high-pressure hydrogen-doped natural gas environmental materials in this example is as follows: figure 1 and figure 2 As shown, it includes natural gas cylinder set 1 for supplying natural gas for testing, hydrogen cylinder set 2 for supplying hydrogen for testing, and argon cylinder set 21 for replacement. The gas cylinder set 1 and hydrogen cylinder set 2 are connected to the low-pressure The buffer tank 3 and the outlet of the low-pressure buffer tank 3 are divided into two paths: one path is connected to the pneumatic booster pump 6, and then the high-pressure buffer tank 7, and the exhaust port of the high-pressure buffer tank 7 is connected to the lower environment on the lower environmental box 14 Casing intake and exhaust ports 32; all the way connected to the pressure reducing valve 4, and then the chromatographic analyzer 5. The chromatographic analyzer 5 can be used to measure the content of each component in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com