Non-irisation-structure-color fabric and preparing method thereof

A technology of structural color and fabric, applied in the direction of plant fiber, animal fiber, textiles and papermaking, etc., can solve the problems of limited methods, high equipment requirements, complicated operation, etc., and achieve the effect of easy control of conditions, low reaction temperature and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Dissolve 0.28 g of dopamine hydrochloride powder in 50 mL of deionized water, then add 0.034 g of anhydrous copper chloride to adjust the pH to 8.5. Add 0.1g of 30% hydrogen peroxide and 0.56g of silane coupling agent KH550 into the dopamine solution, stir well and set aside. Draw 3mL of the solution prepared above, and add it to a plastic petri dish covered with silk power textiles with a diameter of about 5cm, so that the liquid completely covers the surface of the fabric. Cover the plastic petri dishes and place them in a constant temperature vacuum oven (at a temperature of 30° C.) to react for different times (1 h, 1.5 h, 2 h, 3 h), and use a syringe to suck off the unreacted liquid. The treated sample is placed in a constant temperature vacuum oven (at a temperature of 30° C.), and after drying, the structural color can be obtained on the surface of the fabric.

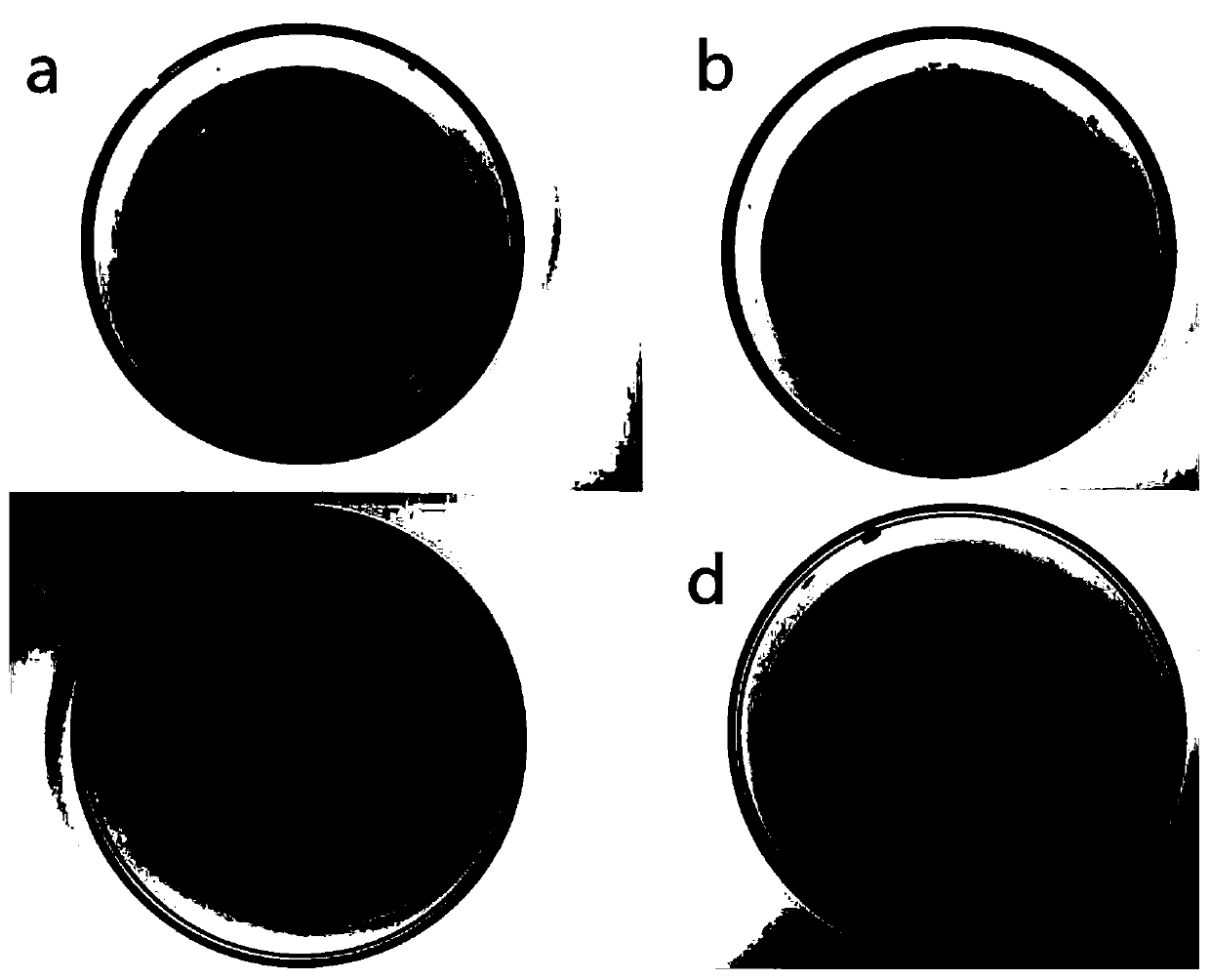

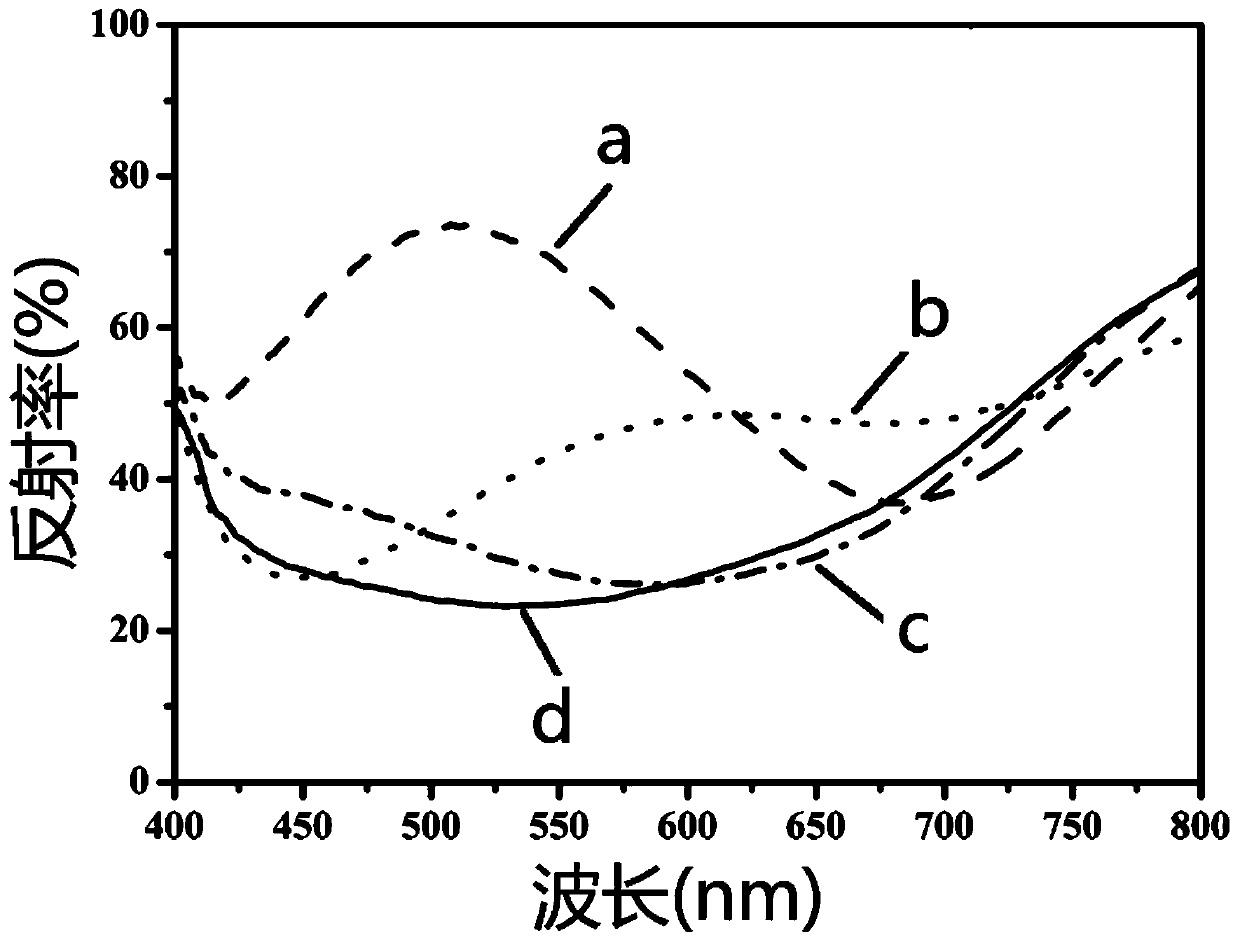

[0039] figure 1 a-d are the optical photographs of the fabrics obtained after reaction for 1h, 1.5h,...

Embodiment 2

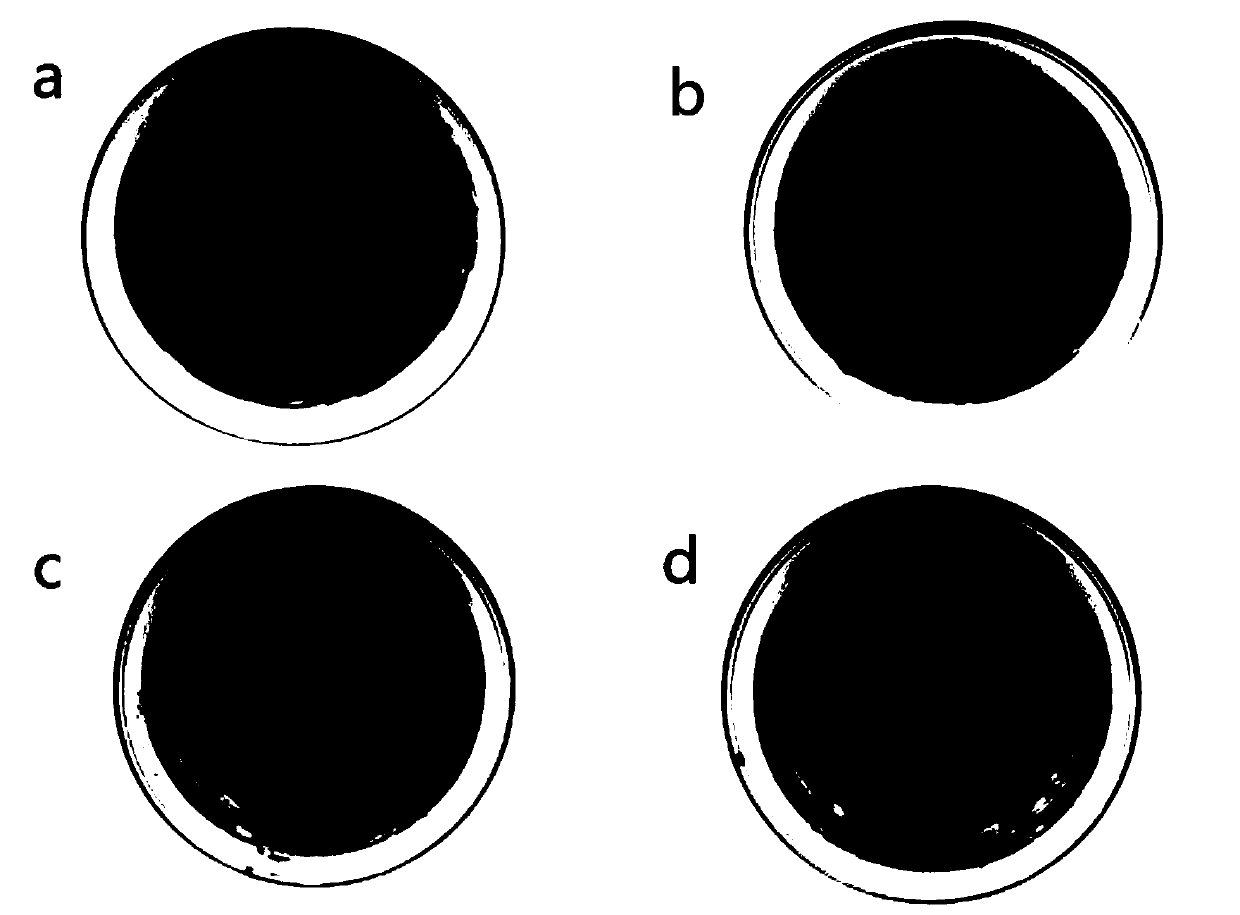

[0041]0.2 g of gallic acid powder was added to 40 mL of deionized water, and 10 mL of ethanol was added to aid dissolution, and then 0.034 g of anhydrous copper chloride was added to adjust its pH value to 8.5. Add 0.1g of 30% hydrogen peroxide and 0.2g of silane coupling agent KH550 into the gallic acid solution, stir well and set aside. Draw 3mL of the solution prepared above, and add it to a plastic Petri dish covered with wool fabric with a diameter of about 5cm, so that the liquid completely covers the surface of the fabric. Cover the plastic petri dish and place it in a constant temperature vacuum oven (at a temperature of 25° C.) to react for different time respectively, and use a syringe to suck off the unreacted liquid. The treated sample is placed in a constant temperature vacuum oven (temperature is 25° C.), and after drying, the structural color can be obtained on the surface of the fabric. Among them, when reacting for 1h, 2h, 3h and 4h, the structural colors of ...

Embodiment 3

[0043] Add 0.3g of ferulic acid powder into 40mL of deionized water, and add 10mL of ethanol to aid dissolution, then add 0.08g of ferric chloride hexahydrate to adjust its pH value to 8.2. Add 0.08g of ferric chloride hexahydrate, 0.1g of 30% hydrogen peroxide and 0.2g of silane coupling agent KH550 into the ferulic acid solution, stir well and set aside. Draw 3mL of the solution prepared above, and add it to a plastic Petri dish covered with cotton fabric with a diameter of about 5cm, so that the liquid completely covers the surface of the fabric. Cover the plastic petri dish and place it in a constant temperature vacuum oven (at a temperature of 40° C.) to react for different time respectively, and use a syringe to suck off the unreacted liquid. The treated sample is placed in a constant temperature vacuum oven (at a temperature of 40° C.), and after drying, the structural color can be obtained on the surface of the fabric. Among them, when reacting for 1h, 2h, 3h and 4h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com