A method for preparing a self-cleaning film on the surface of a solar photovoltaic module

A technology of solar photovoltaic and self-cleaning film, applied in coating and other directions, can solve the problems that cannot be used to transform solar photovoltaic modules, there is no passage for cleaning vehicles to move, it is difficult to achieve high light transmission effect, etc., and achieve good photocatalytic decomposition. The ability of organic matter, good self-cleaning effect, good effect of anti-reflection and anti-reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

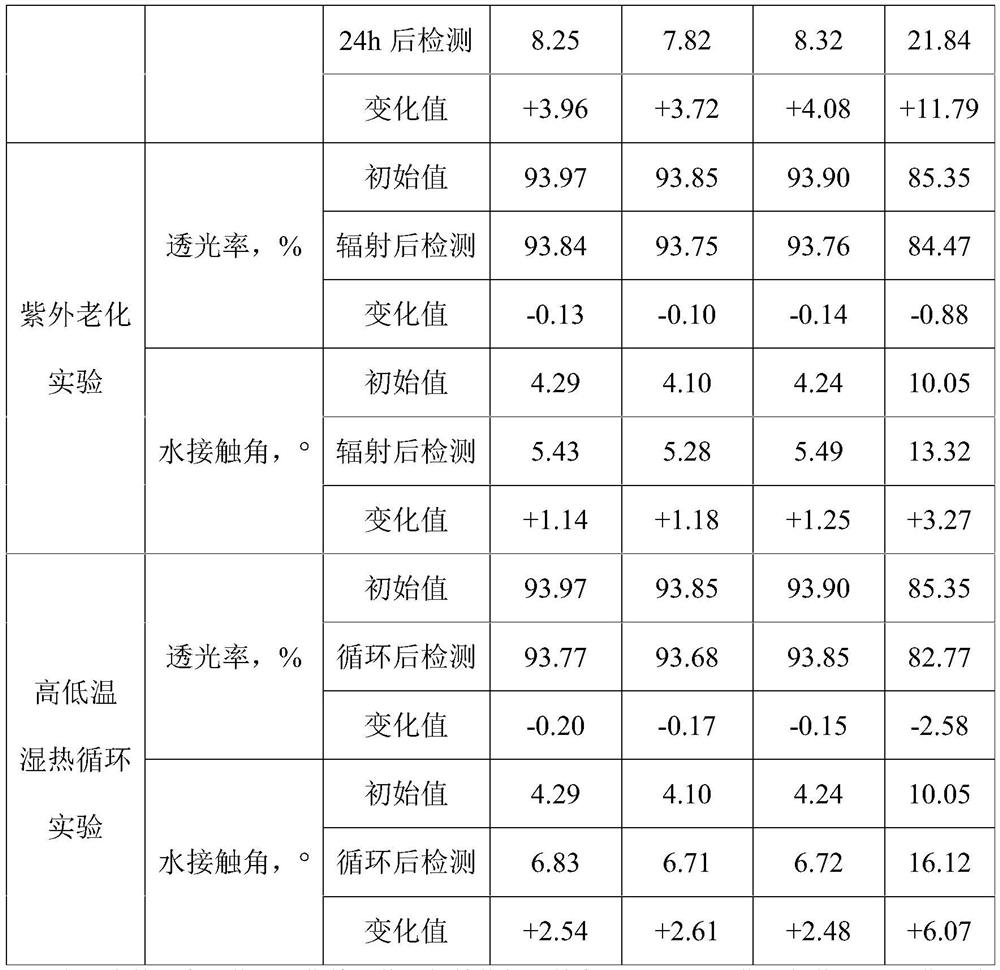

Examples

Embodiment 1

[0034] The preparation method of the self-cleaning film layer on the surface of the solar photovoltaic module of the present embodiment comprises the following steps:

[0035] 1) Take ethylene glycol and n-butyl titanate and mix them uniformly according to the volume ratio of 1:0.24 to obtain mixture A;

[0036] Take ethylene glycol and water and mix them uniformly according to the volume ratio of 1:1.9 to obtain mixture B;

[0037] Under the conditions of ice bath and continuous stirring, according to the volume ratio of mixture A and mixture B of 1:3, mix mixture A and mixture B uniformly to obtain mixture C;

[0038] 2) The mixture C obtained in step 1) was heated up to 105°C at a rate of 5°C for 3.0 hours to remove water in the system, and then heated to 120°C at a rate of 5°C for 2.0 hours to remove butanol produced by the reaction in the system , after cooling to room temperature and performing centrifugation, the rotating speed of centrifugation is 8000rpm to obtain a ...

Embodiment 2

[0046] The preparation method of the self-cleaning film layer on the surface of the solar photovoltaic module of the present embodiment comprises the following steps:

[0047] 1) Take ethylene glycol and n-butyl titanate and mix them uniformly according to the volume ratio of 1:0.25 to obtain mixture A;

[0048] Take ethylene glycol and water and mix them uniformly according to the volume ratio of 1:2.0 to obtain mixture B;

[0049] Under the conditions of ice bath and continuous stirring, according to the volume ratio of mixture A and mixture B of 1:3, mix mixture A and mixture B uniformly to obtain mixture C;

[0050] 2) The mixture C obtained in step 1) was heated at a rate of 5°C to 110°C for 2.5 hours to remove water in the system, and then heated to 125°C at a rate of 5°C for 1.5 hours to remove butanol produced by the reaction in the system , after cooling to room temperature and performing centrifugation, the rotating speed of centrifugation is 8000rpm to obtain a pre...

Embodiment 3

[0058] The preparation method of the self-cleaning film layer on the surface of the solar photovoltaic module of the present embodiment comprises the following steps:

[0059] 1) Take ethylene glycol and n-butyl titanate and mix them uniformly according to the volume ratio of 1:0.26 to obtain mixture A;

[0060] Take ethylene glycol and water and mix them uniformly according to the volume ratio of 1:2.1 to obtain mixture B;

[0061] Under the conditions of ice bath and continuous stirring, according to the volume ratio of mixture A and mixture B of 1:3, mix mixture A and mixture B uniformly to obtain mixture C;

[0062] 2) The mixture C obtained in step 1) was heated at a rate of 5°C to 110°C for 3.0 hours to remove water in the system, and then heated to 120°C at a rate of 5°C for 1.5 hours to remove butanol produced by the reaction in the system , after cooling to room temperature and performing centrifugation, the rotating speed of centrifugation is 8000rpm to obtain a pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com