Implant macro-micro integrated incremental forming preparation method and obtained implant

A technology of incremental forming and implants, applied in the directions of bone implants, diagnosis, echo tomography, etc., can solve the problems such as difficult to overcome, and achieve the effect of enhancing mechanical fitting, shortening the preparation cycle, and reducing the processing chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

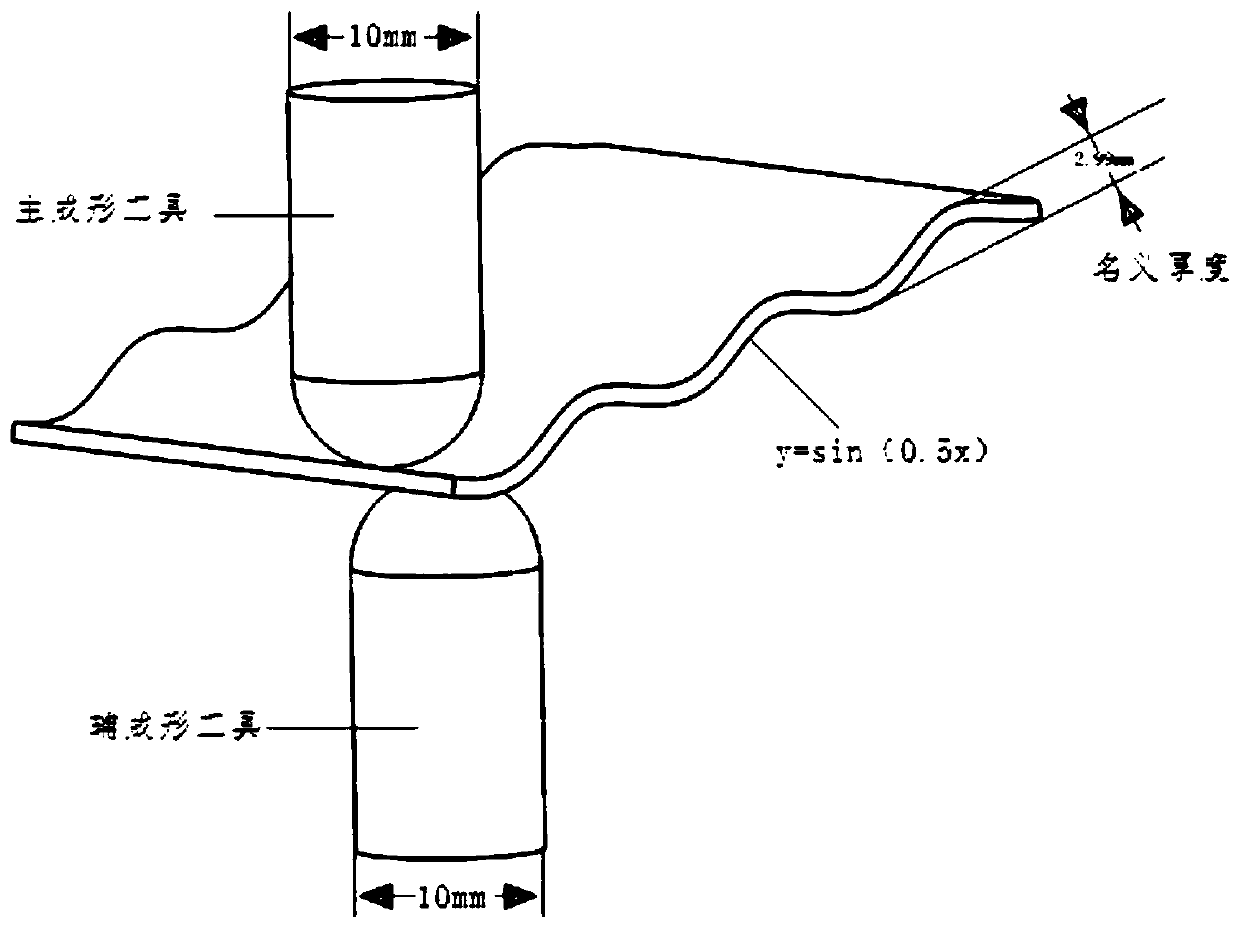

[0057] The preparation method of the macro-micro-integrated progressive forming of the implant provided in this embodiment is as follows:

[0058] First of all, the shape and mechanical properties of the implant are determined according to the patient's condition, and the required shape is processed by macro incremental forming technology. On the basis of ensuring the accuracy of the macroscopic shape and size of the implant, the local nominal thickness of the implant is increased and the overall structure is changed during the macroscopic progressive forming to achieve the thickness distribution of the different positions of the implant and the elastic modulus closer to the original bone. And similar to the mechanical characteristics such as anisotropy of the original bone, the elastic modulus of the structure increases with the decrease of the thickness of the skull. In order to ensure that the implant meets the implant requirements, the improvement effect of the designed st...

specific Embodiment

[0079] The following takes the processing of the skull as an example to illustrate:

[0080] Take the Ti-6Al-4V titanium alloy plate with a size of 100mm×40mm×1mm as an example to illustrate the arc-shaped section (the arc radius R is 5mm, and the central angle of the arc is 106.66°, such as Figure 6 Shown in I) and the difference in modulus of elasticity between the plate. Incrementally forming one of the titanium plates as Figure 6 The size and shape shown on the right are then simulated in ABAQUS. Under the condition of ensuring the same material parameters, one end of the titanium plate is fixed, and a force of 100N is applied to the other end along the positive direction of the X-axis to ensure that the plate is within the elastic deformation range. . The relationship between the maximum displacements of the two titanium plates is the relationship between the elastic moduli of the two. By comparing the maximum displacement, it can be seen that the average elastic mod...

Embodiment 2

[0109] This embodiment provides an implant made in Example 1, which is different from the implant prepared by using the traditional method and titanium mesh plate, and it has the feature that the local section is a smooth curve, and the shape of the cross-sectional structure is as follows Any one of them or a combination of several of them, such as circular arcs, parabolas, sinusoidal curves and other smooth curves. The main purpose of constructing a smooth curve feature in the section is to change the local elastic modulus and mechanical anisotropy of the titanium plate and the thickness distribution of the implant. Generally: the diameter D of the arc is 5-20mm, and the parabola y 2 The p of =2px is 0.1-0.5, the A of the sinusoidal curve y=Asinωx is 1-2, and ω is 0.25-1.

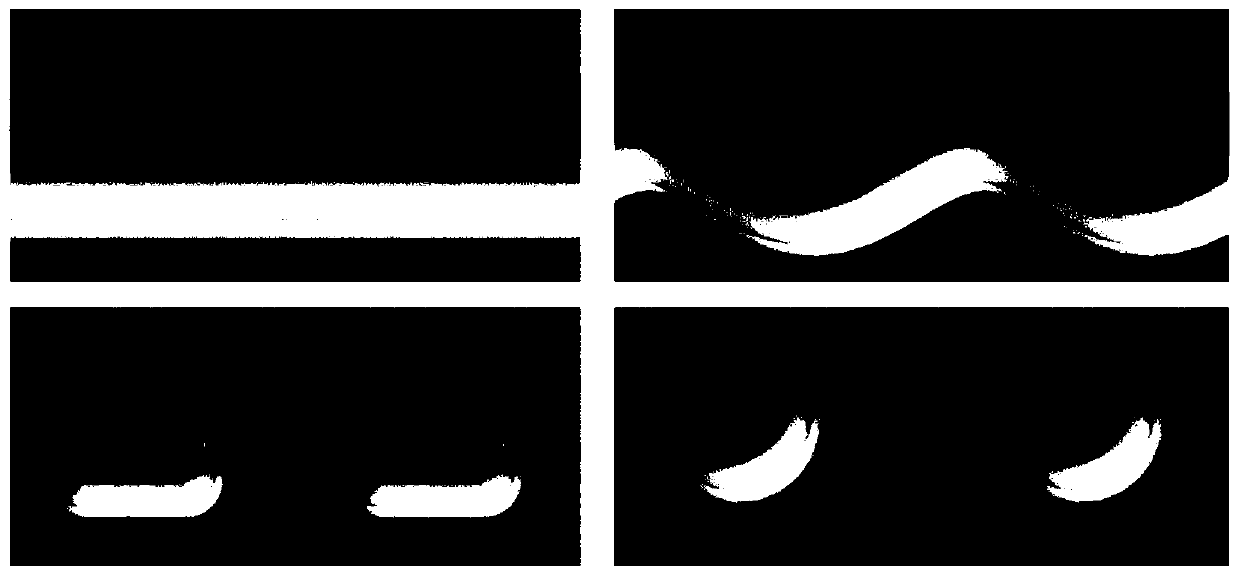

[0110] The surface of the implant is provided with a micron groove structure of a specific shape, such as figure 1 As shown in (c), for example: linear grooves, sinusoidal grooves, rounded rectangular g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com