Graphite dust pollution removal method for ball bed high-temperature gas-cooled reactor

A high-temperature gas-cooled reactor and graphite dust technology, which is applied in the field of nuclear pollution prevention and control, can solve problems such as graphite dust pollution, and achieve the effect of solving the problem of graphite dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

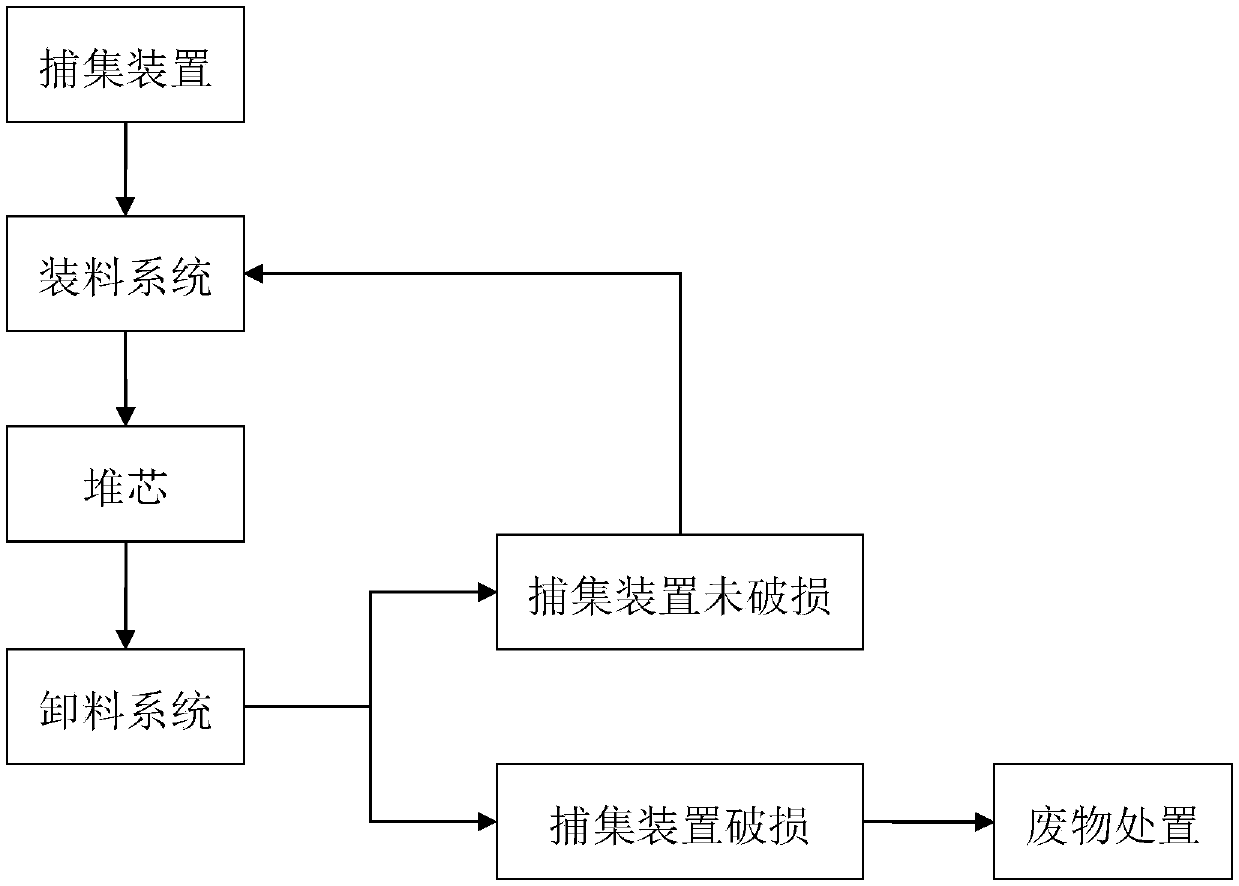

[0045] During the daily operation of the pebble bed pile, according to 5%-10% of the total number of fuel elements, the capture device is sent into the pebble bed pile alternately with the fuel elements through the charging system of the pebble bed pile, and they circulate together in the primary circuit. Captures the dust generated during the cycle phase. After the cycle is completed, the trapping device is discharged from the pebble bed pile through the unloading system of the pebble bed pile for non-destructive testing. If there is no damage, the capture device continues to be used; if it is damaged, the capture device is discontinued, disposed of as solid waste, and, according to the amount of damage, a new capture device is added to the pebble bed pile. It is confirmed that the removal rate of graphite dust in this embodiment is 55%.

Embodiment 2

[0047] During the daily operation of the pebble bed stack, firstly, according to 10%-20% of the total number of fuel elements, the capture device is loaded into the pebble bed stack through the charging system of the pebble bed stack, and then the fuel is loaded through the charging system The element, which starts to circulate in the primary circuit, captures the dust generated during the cycle phase. After the cycle is completed, the trapping device is discharged from the pebble bed pile through the unloading system of the pebble bed pile for non-destructive testing. If there is no damage, the capture device continues to be used; if it is damaged, the capture device is discontinued, disposed of as solid waste, and, according to the amount of damage, a new capture device is added to the pebble bed pile. It is confirmed that the removal rate of graphite dust in this embodiment is 60%.

Embodiment 3

[0049] When the pebble bed pile is shut down for overhaul, according to 50% of the total fuel elements, the capture device is added to the inside of the pebble bed pile through the charging system of the pebble bed pile, and circulates in the primary circuit to capture the dust generated inside the pebble bed pile . After the cycle is completed, the trapping device is discharged from the pebble bed pile through the unloading system of the pebble bed pile for non-destructive testing. If there is no damage, the capture device continues to be used; if it is damaged, the capture device is discontinued, disposed of as solid waste, and, according to the amount of damage, a new capture device is added to the pebble bed pile. It is confirmed that the removal rate of graphite dust in this embodiment is 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com