Nitrogen-doped fluorescent carbon quantum dot, and preparation method and application thereof

A carbon quantum dot, nitrogen doping technology, applied in fluorescence/phosphorescence, chemical instruments and methods, nano-optics, etc., can solve the problem of detecting less nitrite ions, etc., and achieves simple and safe preparation method, excellent fluorescence effect, dispersion uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

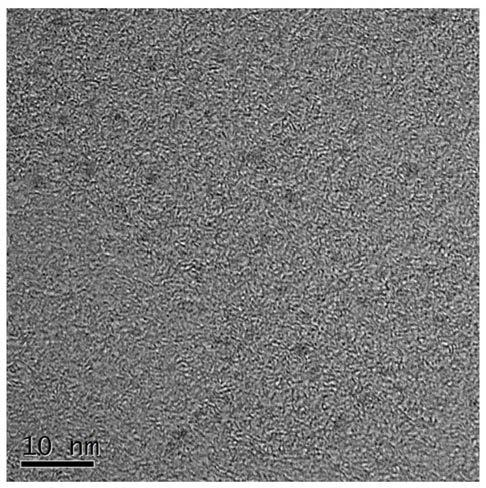

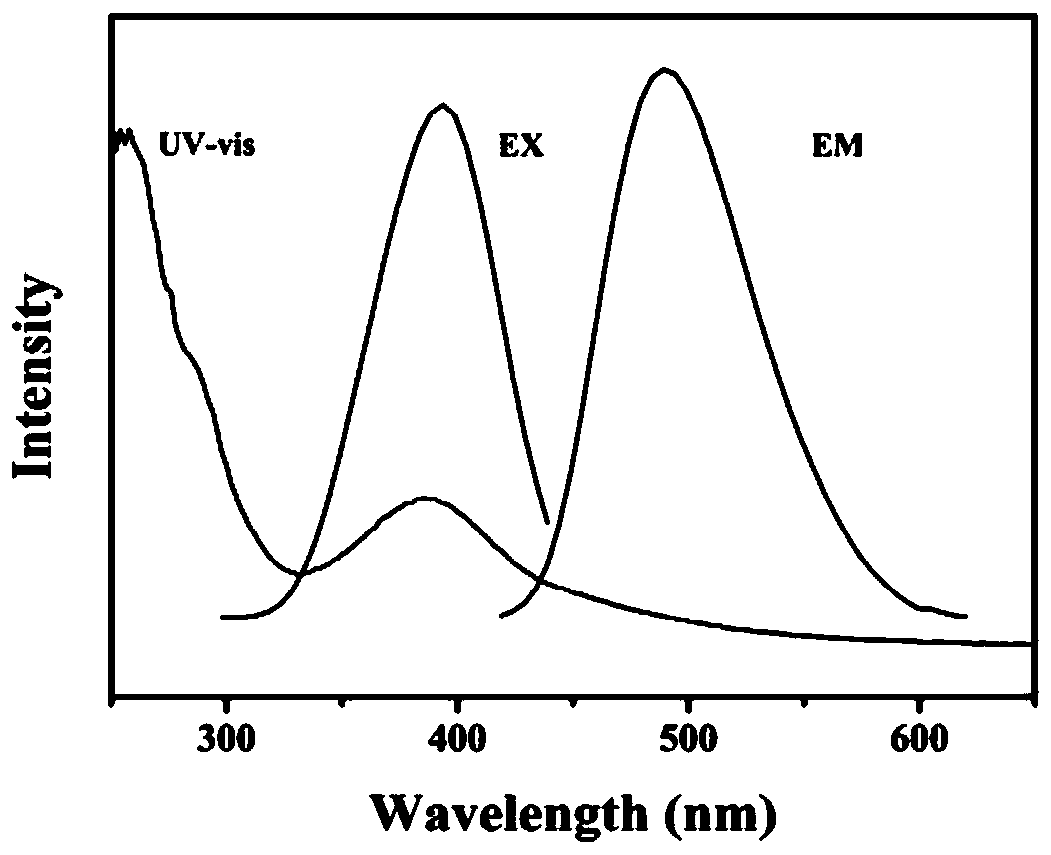

[0036] A preparation method of nitrogen-doped fluorescent carbon quantum dots, m-phenylenediamine is added to ethanol for dissolution to obtain a 0.05mol / L ethanol solution of m-phenylenediamine, and the ethanol solution of m-phenylenediamine is moved into polytetrafluoroethylene Stainless steel high-pressure reaction kettle, placed in an oven to heat the reaction, the reaction temperature is 120 ° C, the reaction time is 12 hours, the reaction product is centrifuged to take the supernatant, and then the supernatant is filtered with a 0.22 μm microporous membrane, and then the processed product is Ethanol was removed by rotary evaporation at a temperature of 40° C., then ultrasonically dispersed in an appropriate amount of distilled water, and finally freeze-dried to obtain fluorescent carbon quantum dot powder.

Embodiment 2

[0038] A preparation method of nitrogen-doped fluorescent carbon quantum dots, adding o-phenylenediamine to ethanol for dissolution to obtain a 1mol / L ethanol solution of o-phenylenediamine, and moving the o-phenylenediamine ethanol solution into polytetrafluoroethylene stainless steel The high-pressure reaction kettle is placed in an oven to heat the reaction. The reaction temperature is 165°C and the reaction time is 8 hours. Ethanol is removed by rotary evaporation at a temperature of 50°C, then ultrasonically dispersed in an appropriate amount of distilled water, and finally freeze-dried to obtain fluorescent carbon quantum dot powder.

Embodiment 3

[0040] A preparation method of nitrogen-doped fluorescent carbon quantum dots, adding p-phenylenediamine to ethanol for dissolution to obtain a 2mol / L ethanol solution of p-phenylenediamine, and moving the p-phenylenediamine ethanol solution into polytetrafluoroethylene stainless steel The high-pressure reaction kettle is placed in an oven to heat the reaction. The reaction temperature is 200°C and the reaction time is 6 hours. Ethanol was removed by rotary evaporation at a temperature of 55°C, then ultrasonically dispersed in an appropriate amount of distilled water, and finally freeze-dried to obtain fluorescent carbon quantum dot powder.

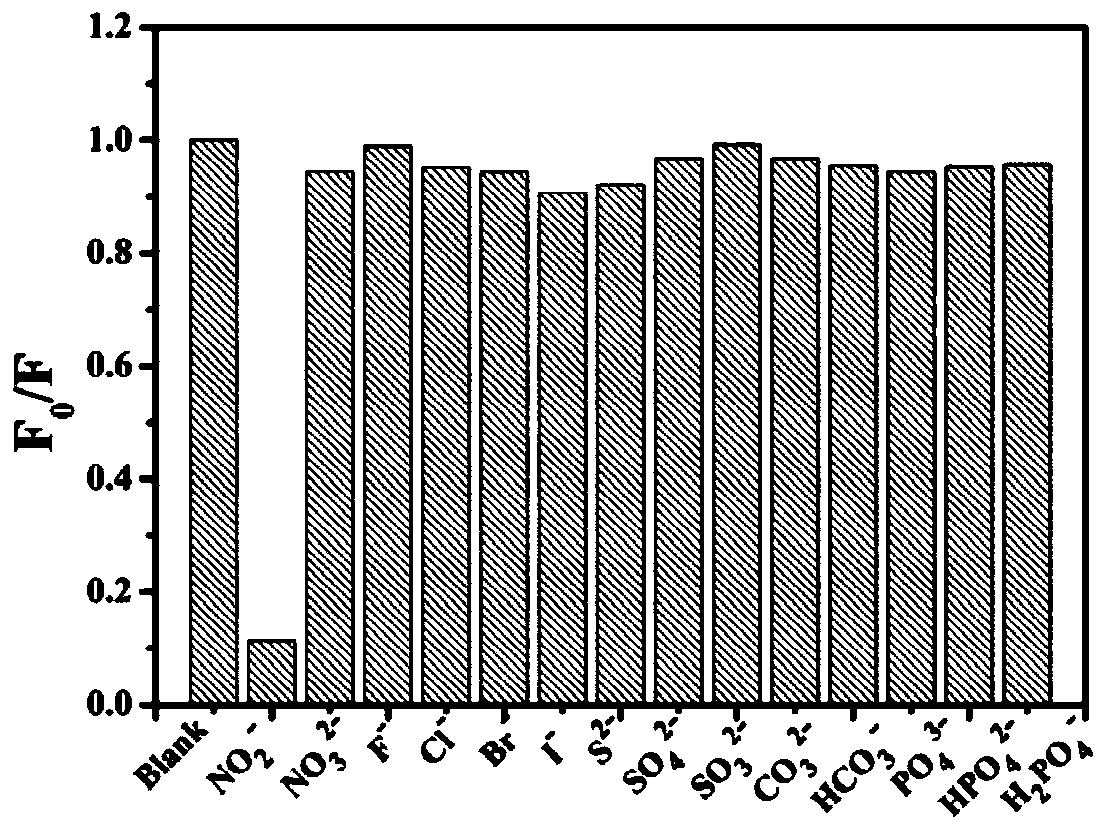

[0041] Prepare a disodium hydrogen phosphate-citrate buffer solution with pH=2, weigh the nitrogen-doped fluorescent carbon quantum dots prepared in Example 1, dissolve them in ultrapure water, and accurately prepare a 0.1 mg / mL carbon quantum dot storage solution . Then take out 300 μL of the above-mentioned carbon quantum dot solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com