A (y 1-x ho x ) 2 the si 2 o 7 Solid solution material and preparation method thereof

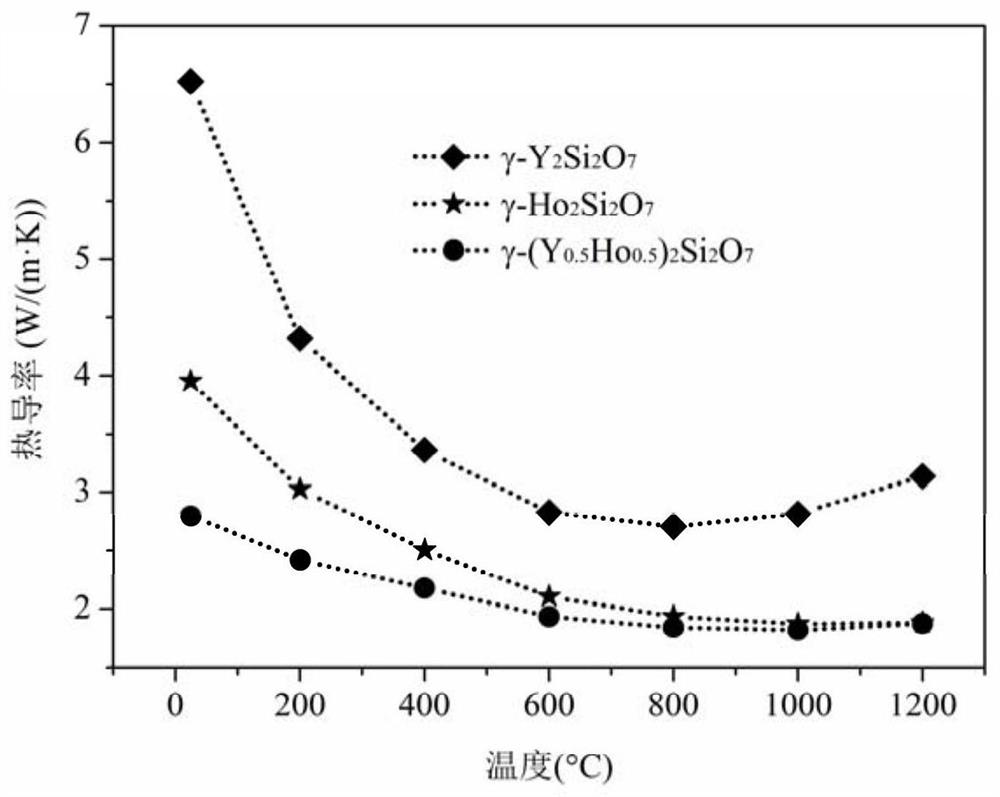

A y1-xhox, solid solution technology, applied in the field of 2Si2O7 solid solution material and its preparation, can solve the problems of lattice distortion phonon scattering, reduce the thermal conductivity of materials, etc., and achieve the effects of shortened reaction time, convenient operation and excellent high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In the specific implementation process, a kind of (Y of the present invention 1-x Ho x ) 2 Si 2 o 7 Solid solution material and preparation method thereof, the specific steps are as follows:

[0023]1. Preparation of solid solution powder: use the mixed powder of yttrium oxide, holmium oxide and silicon dioxide as raw material, and use ethanol as the medium, perform ball milling and mixing for 8-24 hours to form a slurry; then, dry the slurry and sieve it into powder, Pour it into a crucible, then sinter at high temperature in a muffle furnace, the heating rate is 5-10°C / min, the sintering temperature is 1500-1600°C, and the sintering time is 0.5-1.5 hours, and finally (Y 1-x Ho x ) 2 Si 2 o 7 solid solution powder.

[0024] 2. Preparation of solid solution block: Put the solid solution powder after pressureless sintering into a ball mill jar for ball milling and then dry it, and put the dried solid solution powder into a graphite abrasive tool for cold pressin...

Embodiment 1

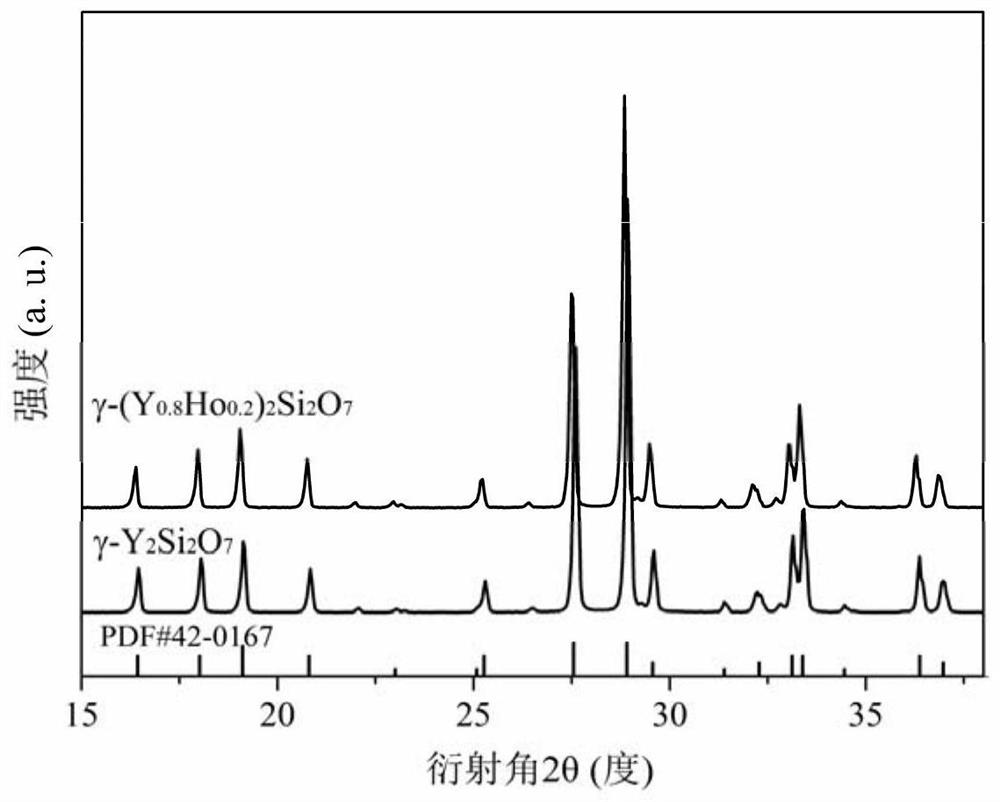

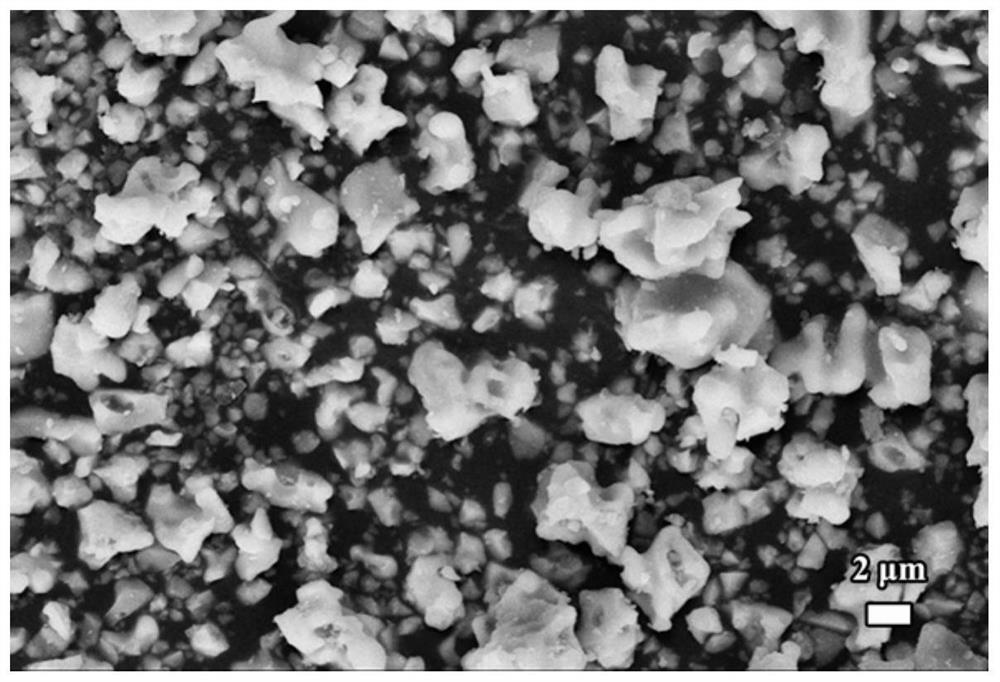

[0028] The original particle size of raw material yttrium oxide, holmium oxide and silicon dioxide powder is 600 orders, with 8 grams of yttrium oxide, 3.35 grams of holmium oxide and 5.32 grams of silicon dioxide (molar ratio is (Y 0..8 Ho 0.2 ) 2 Si 2 o 7 ), using ethanol as the medium, ball milling and mixing for 24 hours to form a slurry; then, the slurry was dried and sieved into powder, poured into a crucible, and then carried out high-temperature pressureless sintering in a muffle furnace with a heating rate of 5 °C / min, the sintering temperature is 1550°C, and the sintering time is 0.5 hours, the (Y 0..8 Ho 0.2 ) 2 Si 2 o 7 Solid solution powder, its XRD spectrum is shown in figure 1 , which can be seen as γ-(Y 0.8 Ho 0.2 ) 2 Si 2 o 7 phase, appearance figure 2 .

Embodiment 2

[0030] The original particle size of raw material yttrium oxide, holmium oxide and silicon dioxide powder is 300 orders, with 10 grams of yttrium oxide, 16.73 grams of holmium oxide and 10.65 grams of silicon dioxide (molar ratio is (Y 0.5 Ho 0.5 ) 2 Si 2 o 7 ), using ethanol as the medium, ball milling and mixing for 8 hours to form a slurry; then, the slurry was dried and sieved into powder, poured into a crucible, and then carried out high-temperature pressureless sintering in a muffle furnace with a heating rate of 10°C / min, the sintering temperature is 1580°C, and the sintering time is 1 hour, the (Y 0.5 Ho 0.5 ) 2 Si 2 o 7 solid solution powder.

[0031] Afterwards, put the solid solution powder after pressureless sintering into a ball mill jar for ball milling and then dry it, and put the dried solid solution powder into a graphite abrasive tool for cold pressing, the applied pressure is 5MPa, and the cold pressing time is 15min. Sintered in a hot-press furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com