Aluminum bronze casting molten casting process

A casting process, aluminum bronze technology, applied in the field of melting casting process, can solve the problems of internal slag inclusion, decarburization, large typical casting defects, etc., and achieve the effect of improving the quality of castings and conveniently avoiding slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0032] Aluminum bronze casting fusion casting process, comprising the following steps:

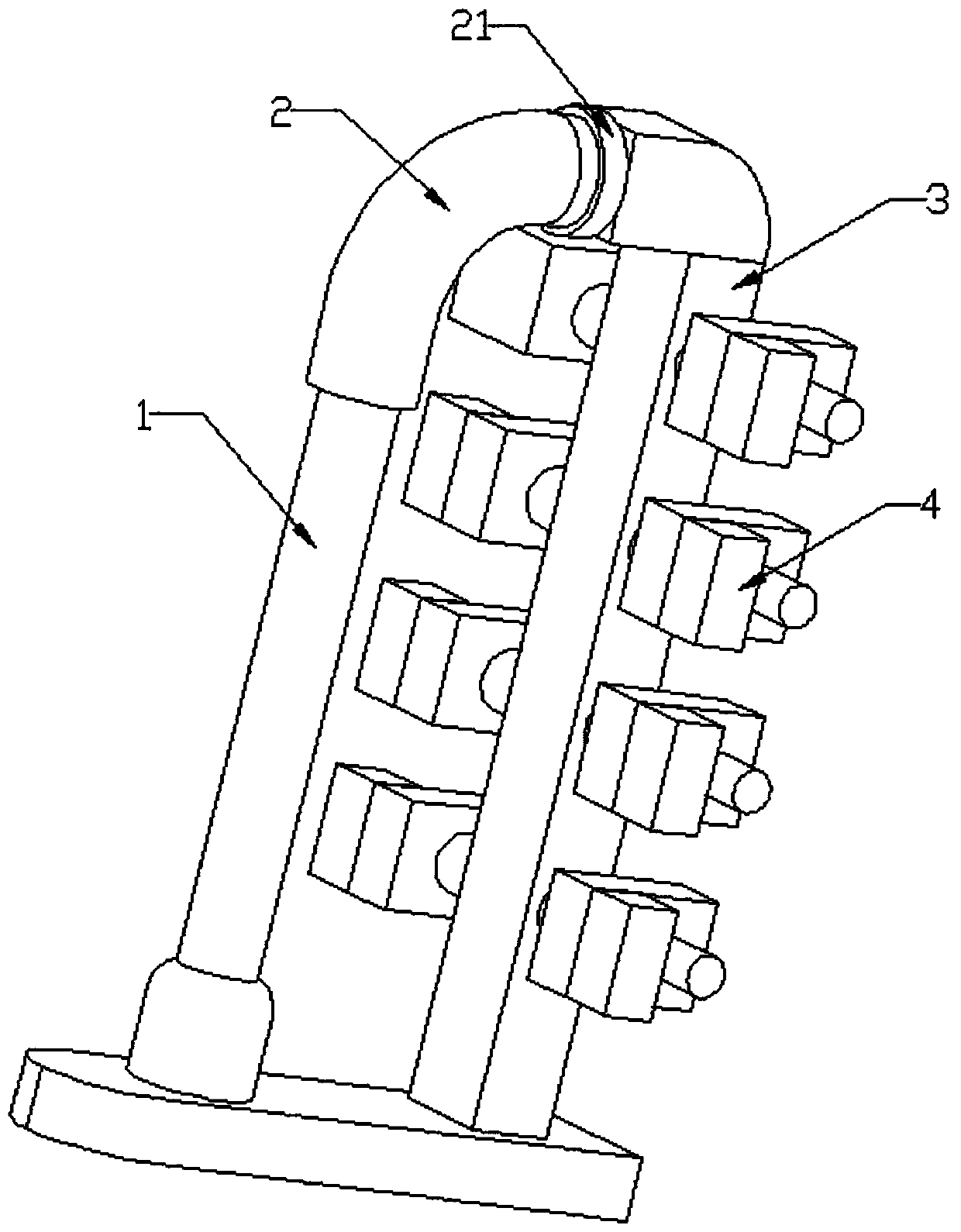

[0033] 1) Preparation of wax pattern: melt the paraffin wax and shape it into a wax pattern. The wax pattern includes a U-shaped runner and a plurality of parts. The U-shaped runner consists of the first straight section 1, the second The direct current section 3 and the arc connection section 2 are composed of a ceramic filter sheet 21 connected to the arc connection section 2, and the diameter of the ceramic filter sheet 21 is larger than the diameter of the arc connection section, and the plurality of The part shape 4 is symmetrically arranged on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com