A kind of superabsorbent polymer hydrogel antibacterial sponge and its preparation method and application

A technology of water-absorbing polymers and hydrogels, applied in applications, pharmaceutical formulations, surgery, etc., can solve problems such as limited hemostatic ability, degradation, and high cost, and achieve the effects of stable structure, high strength, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

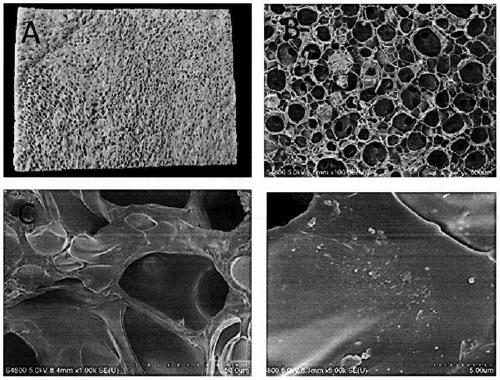

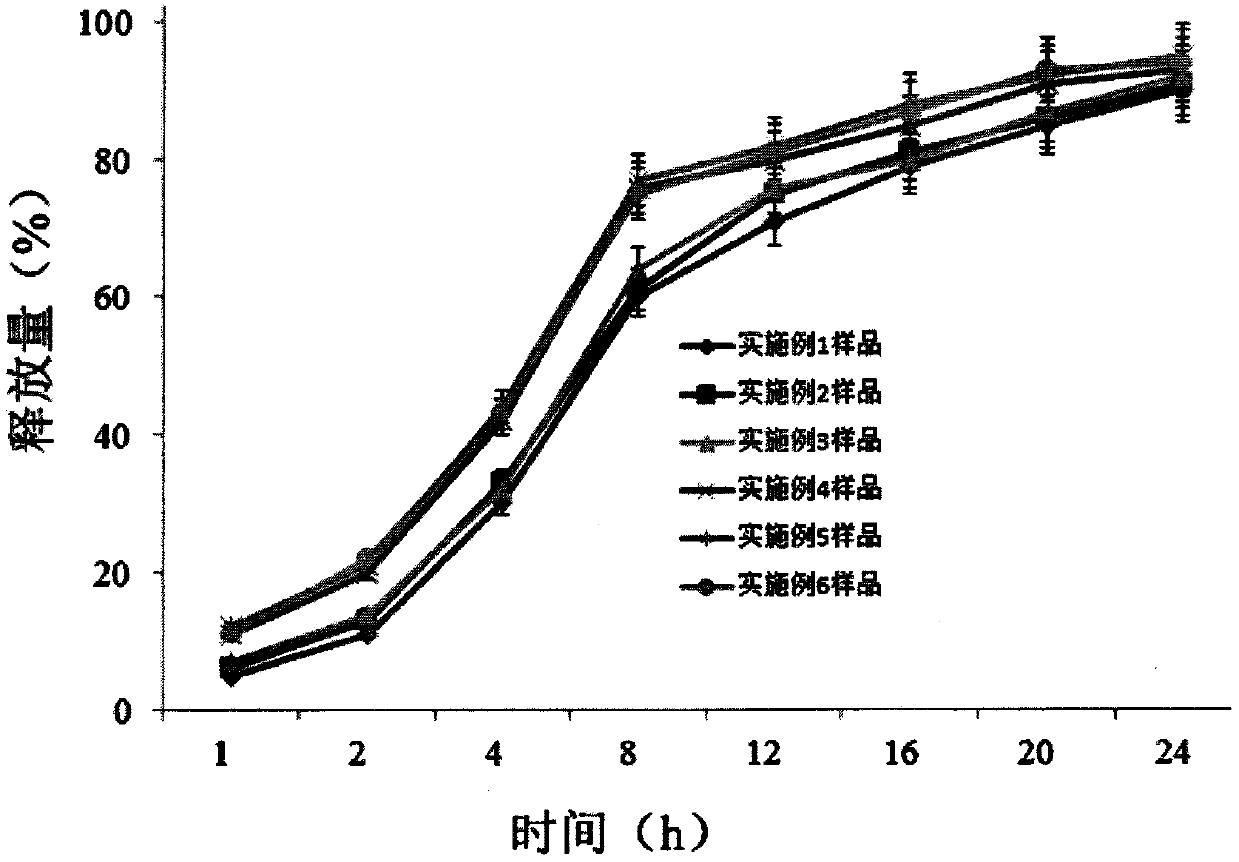

[0051] The preparation of embodiment 1 superabsorbent polymer hydrogel antibacterial sponge sample 1

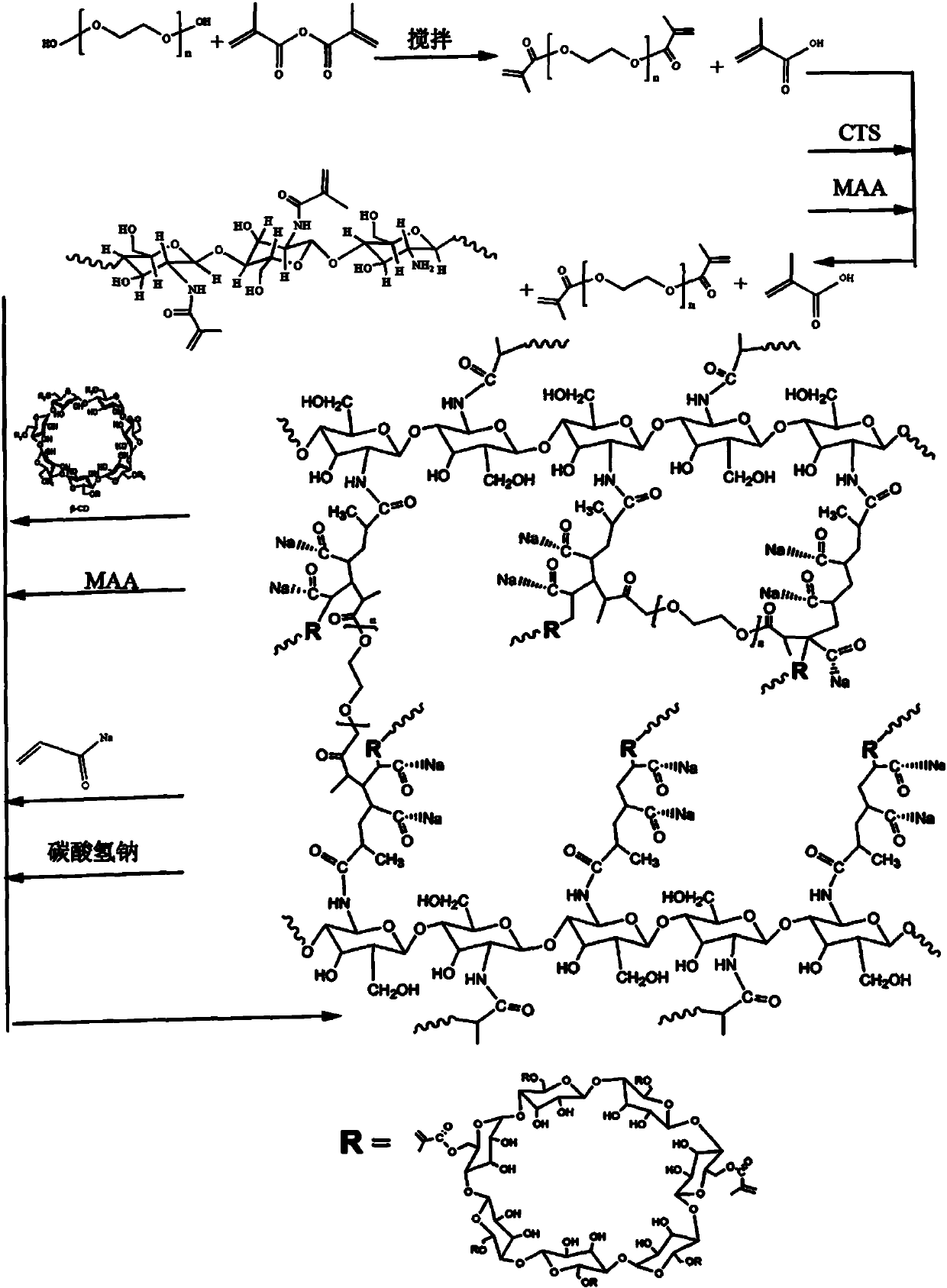

[0052] Using methacrylic anhydride (MAA)-capped polyethylene glycol (PEG) as a crosslinking agent, sodium polyacrylate as a water-absorbing polymer, MAA-capped cyclodextrin as an antibacterial slow-release carrier, and MAA-capped chitosan ( MAACTS) reaction, prepare chitosan derivative resin, load broad-spectrum antibacterial function fungicide iodine, its synthesis process is as follows:

[0053]

[0054] Step 1: Preparation of Backbone Compounds

[0055] Add 3 ml of methacrylic anhydride to 100 ml of chitosan solution with a volume fraction of 2%, and mechanically stir for 120 min at a stirring speed of 1000 to 2000 red / min. Methacrylic anhydride-terminated chitosan (MAACTS) was obtained.

[0056] Step 2: Preparation of Crosslinker

[0057] Add 1g of PEG-6000 into 50ml of chloroform, stir magnetically for 30min, add 1ml of methacrylic anhydride, stir magnetically for ...

Embodiment 2

[0064] The preparation of embodiment 2 superabsorbent polymer hydrogel antibacterial sponge sample 2

[0065] Step 1: Add 15ml of 2wt% maleic anhydride (dimethyl sulfoxide as solvent) into 100ml of chitosan solution with a volume fraction of 2%, and mechanically stir for 120min at a stirring speed of 1000-2000red / min. Maleic anhydride-terminated chitosan (MCTS) was obtained.

[0066] Step 2: Add 1g of PEG-6000 into 50ml of chloroform, stir magnetically for 30min, add 1g of maleic anhydride, stir magnetically for 6h, volatilize the chloroform, and obtain maleic acid-capped PEG-6000 white powder.

[0067] Step 3: Add 1g of β-cyclodextrin to 50ml of acrylic acid, stir magnetically for 10min, add 15ml of 2wt% maleic anhydride (dimethyl sulfoxide as solvent), and stir magnetically for 6h to obtain maleic acid-capped β-cyclodextrin fine solution.

[0068] Step 4: Add 100g NaOH to 300ml deionized water in a salt ice bath, and stir mechanically. When the NaOH solution dropped to 0°...

Embodiment 3

[0072] The preparation of embodiment 3 superabsorbent polymer hydrogel antibacterial sponge sample 3

[0073] Step 1: Add 5 ml of 2 wt % itaconic anhydride (dimethyl sulfoxide as solvent) to 100 ml of chitosan solution with a volume fraction of 2%, and mechanically stir for 120 min at a stirring speed of 1000 to 2000 red / min. Itaconic acid-terminated chitosan (ICTS) was obtained.

[0074] Step 2: Add 1g of PEG-6000 into 50ml of chloroform, stir magnetically for 30min, add 1g of itaconic anhydride, stir magnetically for 6h, evaporate the chloroform, and obtain white powder of PEG-6000 capped with itaconic acid.

[0075] Step 3: Add 1g of β-cyclodextrin to 50ml of acrylic acid, stir magnetically for 10min, add 5ml of 2wt% itaconic anhydride (dimethyl sulfoxide as solvent), stir magnetically for 6h, volatilize chloroform, and obtain itaconic acid-capped β-cyclodextrin solution.

[0076]Step 4: Add 100g NaOH to 300ml deionized water in a salt ice bath, and stir mechanically. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com