A kind of nay molecular sieve with high silicon-aluminum ratio and small grain size and preparation method thereof

A technology with high silicon-aluminum ratio and small crystal grains, which is applied in the fields of aluminum silicate, chemical instruments and methods, silicates, etc., can solve the problems of small increase in silicon-aluminum ratio, complex process operation, and low utilization rate of silicon sources and other problems, to achieve the effect of improving mass transfer and heat transfer rate, high solid content, and improving the utilization rate of silicon source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

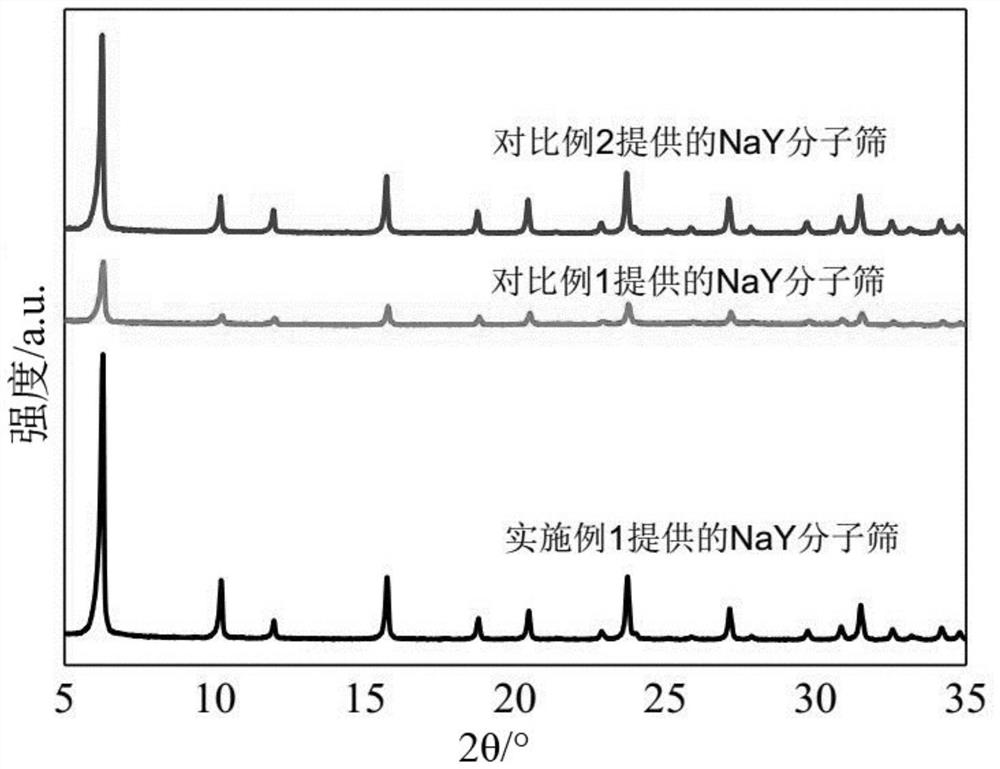

Embodiment 1

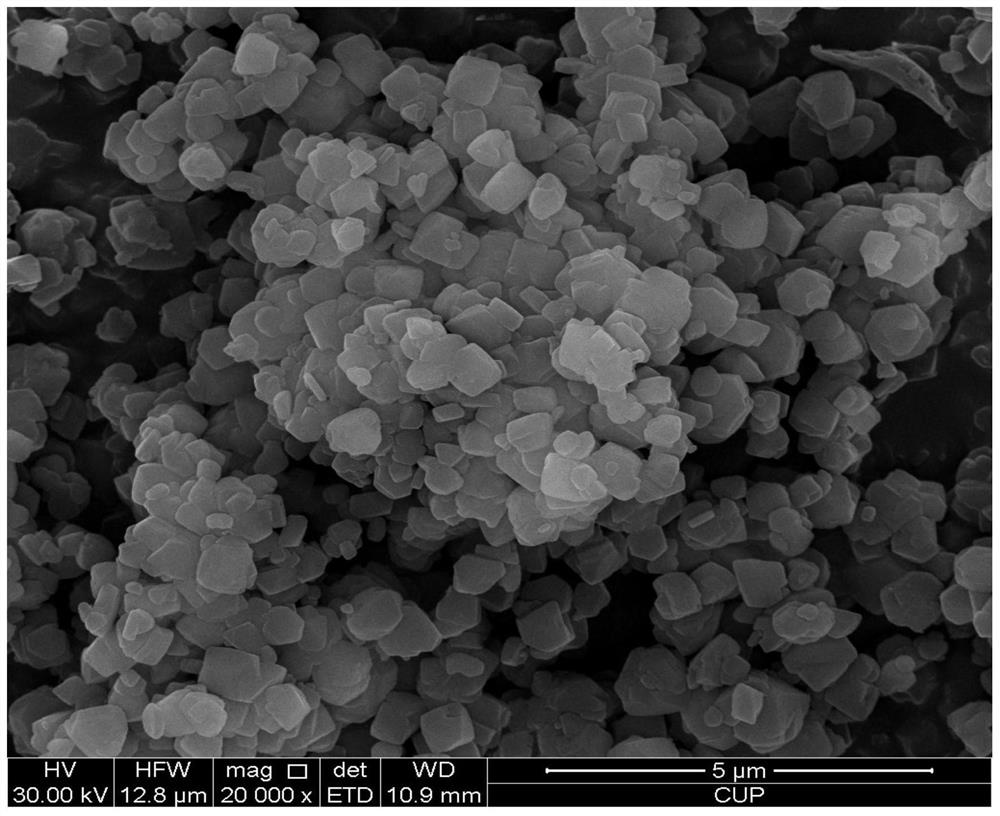

[0056] This implementation provides a kind of high silicon aluminum ratio small grain NaY molecular sieve and its preparation method, comprising the following steps:

[0057] Mix the microsphere silica gel with the ethanol solution of polyethylene glycol, mix in a closed container at 500°C for 6 hours under nitrogen atmosphere, age at room temperature for 2 hours, then wash with water until the pH value is 7, and finally dry to obtain the highly active crude Porous microsphere silica gel;

[0058] Take by weighing 15.13g sodium hydroxide solid (Beijing Chemical Plant, 96wt%) and be dissolved in 48.326g deionized water, after cooling to room temperature, add 3.68g sodium metaaluminate (Tianjin Jinke Fine Chemical Research Institute, Al 2 o 3 Content is 45wt%, Na 2 O content is 41wt%), makes high alkalinity sodium metaaluminate solution, after stirring, add 86.5g water glass (SiO 2 The content is 21.38wt%, Na 2 The content of O is 5.86wt%), mixed uniformly and aged under agi...

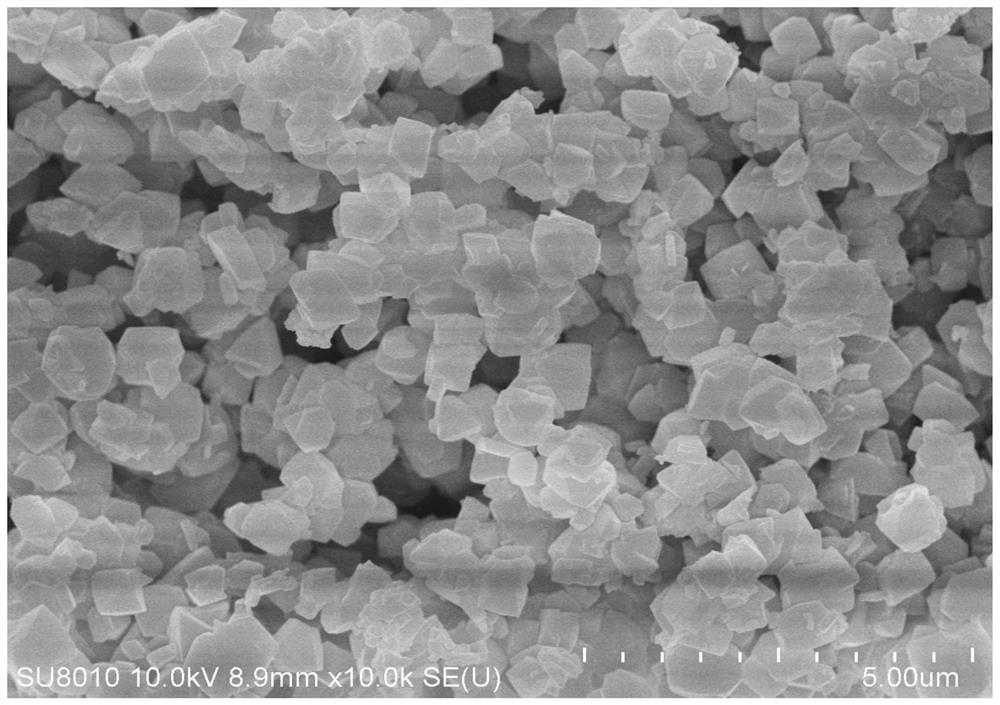

Embodiment 2

[0063] This implementation provides a kind of high silicon aluminum ratio small grain NaY molecular sieve and its preparation method, comprising the following steps:

[0064] Mix silica and polyethylene glycol ethanol solution, mix in a closed container at 500°C for 6 hours under nitrogen atmosphere, age at room temperature for 2 hours, then wash with water until the pH value is 7, and finally dry to obtain high-activity white carbon black. carbon black;

[0065] The preparation of directing agent is with embodiment 1;

[0066] Weigh 8.27g of high-activity white carbon black and place it in a beaker, add 24g of deionized water, stir and mix evenly, then weigh 4g of sodium metaaluminate, add and mix evenly, add 15.88g of the above-mentioned guiding agent, stir evenly Form a brown gel state, the total gel mass of the reaction mixture is 52.15g, and the proportioning is 2.95Na 2 O: Al 2 o 3 : 8.50SiO2 2 : 102.06H 2 O, the solid content is 31.93%;

[0067] Put it into a sta...

Embodiment 3

[0069] This implementation provides a kind of high silicon aluminum ratio small grain NaY molecular sieve and its preparation method, comprising the following steps:

[0070] Mix solid silicic acid with ethanol solution of polyethylene glycol, mix in a closed container at 200°C for 30 hours under nitrogen atmosphere, age at room temperature for 12 hours, then wash with water until the pH value is 7, and finally dry to obtain highly active silicon acid;

[0071] The preparation of directing agent is with embodiment 1;

[0072] Weigh 7.72g of highly active silicic acid and place it in a beaker, add 24g of deionized water, stir and mix evenly, then weigh 4g of sodium metaaluminate, add and mix evenly, add 14.82g of the above-mentioned guiding agent, stir evenly and form Brown gel state, the total gel mass of the reaction mixture is 50.54g, and the proportion is 2.86Na 2 O: Al 2 o 3 : 7.98SiO2 2 : 100.44H 2 O, the solid content is 31.28%;

[0073] Put it into a stainless st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com