Nitrogen-doped porous carbon material, preparation method thereof and application of nitrogen-doped porous carbon material in supercapacitor

A technology of nitrogen-doped porous carbon and melamine, which is applied in the preparation/purification of carbon, hybrid capacitor electrodes, etc., can solve the problems of uneconomical amount of activator, insufficient mixing, and dangerous activator, etc., and achieves easy large-scale production, Inexpensive and highly controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] As a detailed example of the preparation of nitrogen-doped porous carbon materials, the preparation process is as follows: (1) Disperse melamine in water, then add formaldehyde solution, and continue to heat and stir until the melamine is completely dissolved, then add potassium nitrate and of polyethylene glycol, and continue stirring until dissolved. (2) Subsequently, the obtained clear solution is placed in an oven at a certain temperature and kept warm for a period of time to continuously evaporate moisture until a xerogel is formed. (3) Place the obtained xerogel in an inert gas, and activate it at a certain temperature for a period of time. (4) After the activated material is etched with hydrochloric acid, washed with water and dried, the prepared nitrogen-doped porous carbon material is obtained.

[0037] The present invention mixes the activator (potassium salt) and the carbon source by the sol-gel method, which is an original method. Since a uniform sol syste...

Embodiment 1

[0040] Get 1g of melamine and disperse it in 20ml of water, add 1.7g of formaldehyde solution (mass fraction is 37wt%), stir constantly at 70°C for 20 minutes, then add 3g of potassium nitrate and 6g of polyethylene glycol with a molecular weight of 10000, continue Stir until completely dissolved. The obtained solution was dried in an oven at 80° C. for 24 h to form a xerogel. Place the xerogel in the middle of the tube furnace, pass through 300sccm Ar, raise the temperature from room temperature to 800°C at a rate of 10°C / min, keep it at 800°C for 4 hours, and finally cool down with the furnace. The obtained sample was put into 3 mol / L hydrochloric acid aqueous solution, soaked for 24 hours, filtered, washed and dried to obtain a nitrogen-doped porous carbon material.

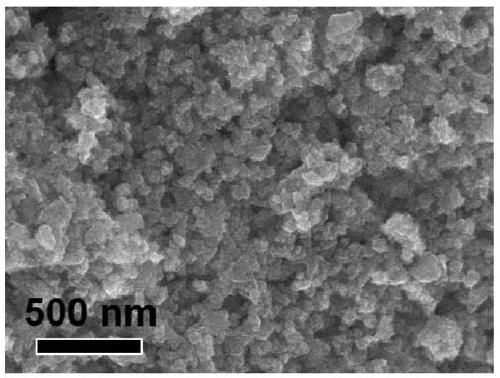

[0041] figure 1 It is the SEM and TEM photos of the three-dimensional hierarchical porous carbon material prepared in Example 1 at different magnifications. Such as figure 1 As shown in (a) and (b), abunda...

Embodiment 2

[0043] Get 1g of melamine and disperse it in 20ml of water, add 1.7g of formaldehyde solution (mass fraction is 37wt%), stir constantly at 70°C for 20 minutes, then add 2g of potassium nitrate and 6g of polyethylene glycol with a molecular weight of 10000, continue Stir until completely dissolved. The obtained solution was dried in an oven at 80° C. for 24 h to form a xerogel. Place the xerogel in the middle of the tube furnace, pass through 300sccm Ar, raise the temperature from room temperature to 800°C at a rate of 10°C / min, keep it at 800°C for 4 hours, and finally cool down with the furnace. The obtained sample was put into 3mol / L hydrochloric acid aqueous solution, soaked for 24h, filtered, washed and dried to obtain a nitrogen-doped porous carbon material. For its microscopic appearance, see Figure 5 , the rich pore structure can be clearly seen in the figure. Image 6 (a) is the nitrogen adsorption-desorption curve of the obtained nitrogen-doped porous carbon materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com