A kind of polyolefin film, preparation method and solar battery backplane

A polyolefin film, polyolefin technology, applied in the field of film, can solve the problems of complex process, limited effect, affecting the adhesion of polyolefin materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

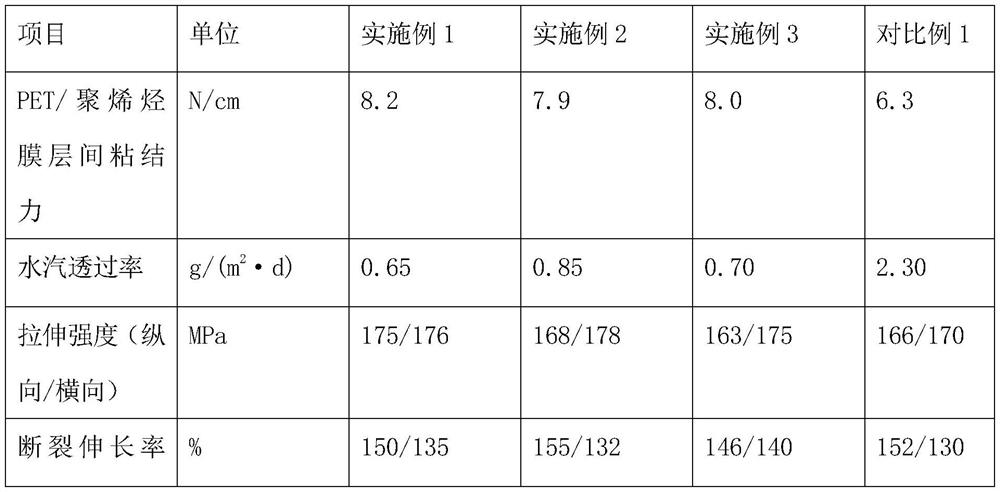

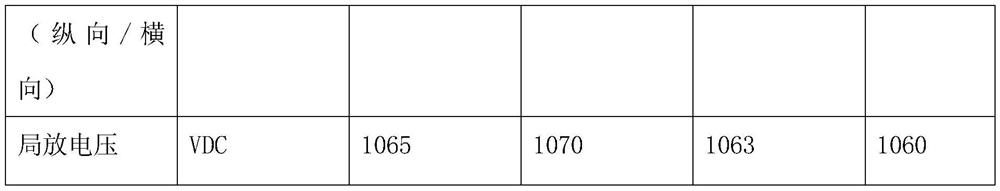

Examples

Embodiment 1

[0043] i) Select low-density polyethylene (LDPE), phosphate glass powder treated with silane, and PE-MAH as raw materials, and vacuum-dry in an oven at 85° C. for 24 hours to remove adsorbed moisture.

[0044] ii) Granulation: Weigh 100kg PE-MAH and 100kg phosphate glass powder respectively, mix them uniformly and add them into a twin-screw extruder for melt blending, cool and pelletize after extrusion to obtain PE-MAH / phosphate Glass masterbatch. The temperature in each zone of the extruder was 220°C.

[0045] iii) Co-extrusion: Take 50kg of the masterbatch obtained in step (i) and mix it evenly with 50kg of polyethylene slices, add A-layer extruder to extrude the middle layer of polyolefin film; 89kg of polyethylene slices, 2kg of anti-hydrolysis agent , 3kg of UV absorber, 1kg of light stabilizer, and 5kg of titanium dioxide are mixed evenly, and added to the B-layer extruder to extrude the polyolefin layer arranged on both sides;

[0046] iv) Cast sheet and biaxial stret...

Embodiment 2

[0051] i) Use polypropylene (PP), phosphate glass powder treated with silane, and PP-MAH as raw materials, and vacuum-dry in an oven at 85° C. for 24 hours to remove adsorbed moisture.

[0052] ii) Granulation: Weigh 400kg PE-MAH and 100kg phosphate glass powder respectively, mix them evenly and add them into a twin-screw extruder for melt blending, cool and pelletize after extrusion to obtain PE-MAH / phosphate Glass masterbatch. The temperature in each zone of the extruder was 220°C.

[0053] iii) Co-extrusion: Take 90kg of the masterbatch obtained in step (i) and mix it with 10kg polyethylene slices evenly, and add it to the A-layer extruder to extrude the middle layer of polyolefin film; 97kg polyethylene slices, 0.2kg anti-hydrolysis agent, 0.5kg UV absorber, 0.5kg light stabilizer, and 0.5kg titanium dioxide are mixed evenly, and added to the B-layer extruder to extrude the polyolefin layer arranged on both sides;

[0054] iv) Cast sheet and biaxial stretching: the three...

Embodiment 3

[0059] i) Use polypropylene (PP), phosphate glass powder treated with silane, and PP-MAH as raw materials, and vacuum-dry in an oven at 85° C. for 24 hours to remove adsorbed moisture.

[0060] ii) Granulation: Weigh 200kg PE-MAH and 100kg phosphate glass powder respectively, mix them uniformly and add them into a twin-screw extruder for melt blending, cool and pelletize after extrusion to obtain PE-MAH / phosphate Glass masterbatch. The temperature in each zone of the extruder was 220°C.

[0061] iii) Co-extrusion: Take 45kg of the masterbatch obtained in step (i) and mix it evenly with 10kg of polyethylene slices, and add it to the A-layer extruder to extrude the middle layer of polyolefin film; 93kg of polyethylene slices, 1.1kg of anti-hydrolysis Agent, 1.75kg UV absorber, 0.75kg light stabilizer, 3.4kg titanium dioxide are mixed evenly, and added to the B-layer extruder to extrude the polyolefin layer arranged on both sides;

[0062] iv) Cast sheet and biaxial stretching:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com