System and method for reducing abrasive particle flow extrusion and oscillating residual stress

A technology of residual stress and abrasive flow, which is applied to grinding/polishing equipment, parts of grinding machine tools, metal processing equipment, etc., can solve the problems of irreversible residual stress and stress concentration on the bearing surface, and improve the efficiency of stress release , sufficient stress release, direct processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

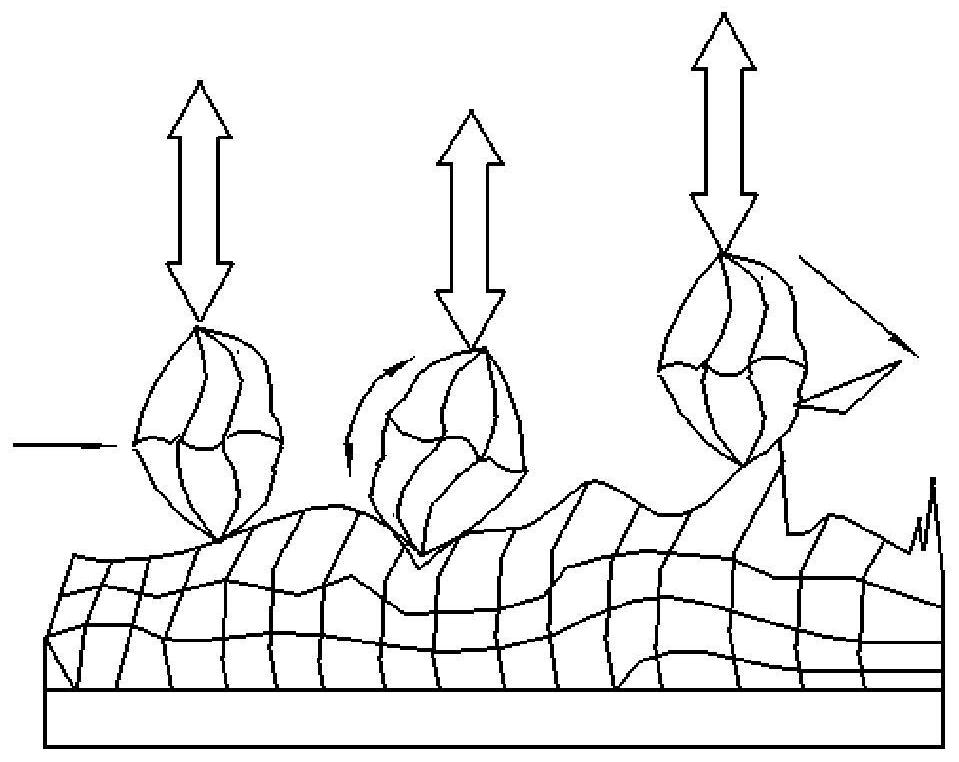

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

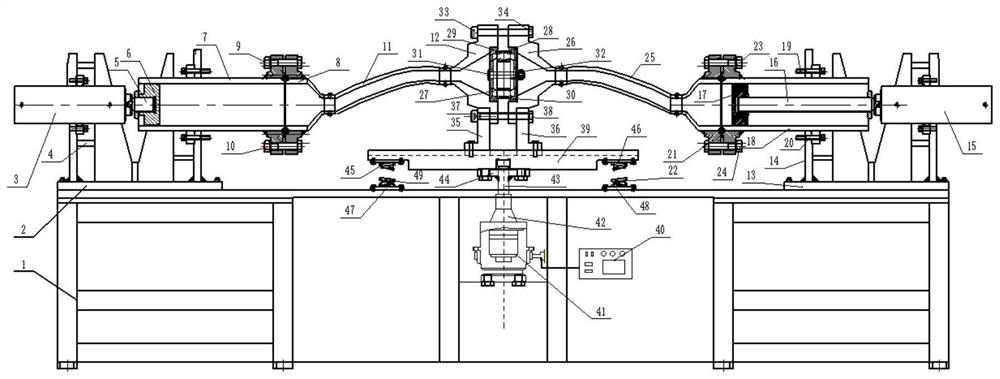

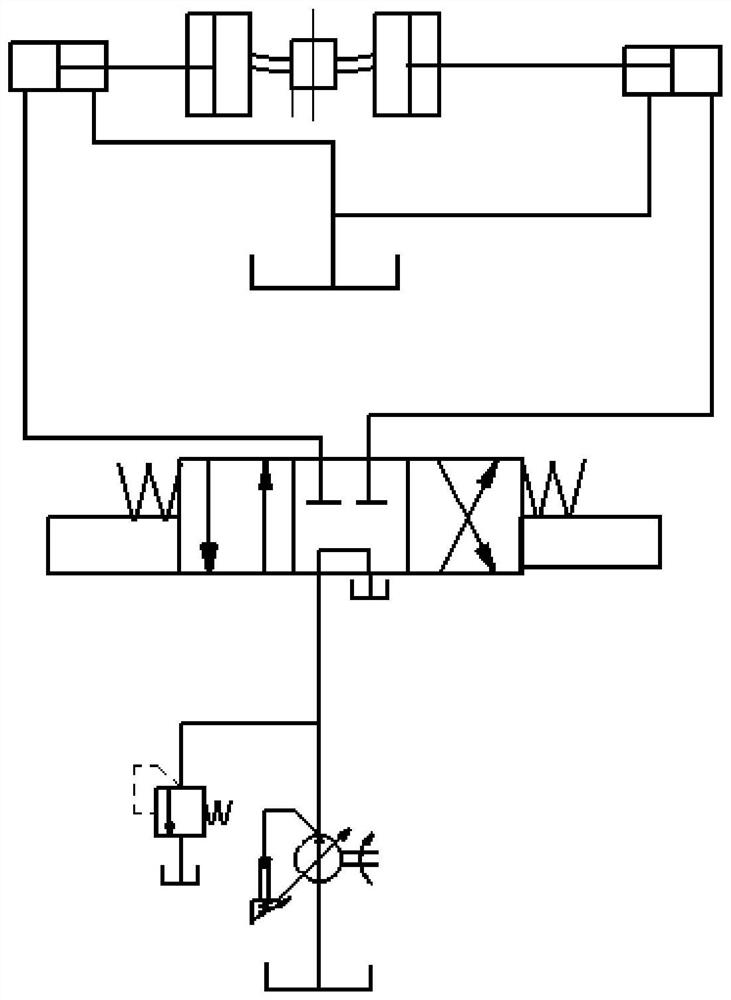

[0029]1-frame; 2-connecting plate; 3-left hydraulic cylinder; 4-left support rib; 5-left piston rod; 6-left push piston; 7-left cylinder; 8-left push cylinder cover; 9-bolt; 10-bolt; 11-left carbon fiber hose; 12-left housing; 13-right connecting plate; 14-right supporting rib; 15-right hydraulic cylinder; 16-right piston rod; 17-right push Material piston; 18-right material cylinder; 19-bolt; 20-bolt; 21-right push piston cylinder head; 22-spring; 23-nut; 24-nut; 25-right carbon fiber hose; 25-bearing inner ring ;26-right housing; 27-bearing inner ring; 28-bearing outer ring; 29-left clamp body; 30-right clamp body; 31-bolt; 32-nut; 33-bolt; 34-nut; 35-left T-block; 36-right T-block; 37-bolt; 38-nut; 39-T-type vibration table; 40-ultrasonic generator; 41-transducer; 42-horn; 43-vibration rod; 44-welding flange; 45-spring support seat; 46-spring support seat; 47-spring support seat; 48-spring support seat; 49-spring;

[0030] Such as figure 1 As shown, the device of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com