Plant soft capsule and preparation method and application thereof

A soft capsule and plant technology, applied in the field of plant soft capsule and its preparation, can solve problems such as low production cost and low oil leakage rate, and achieve the effects of low oil leakage rate, excellent film-forming property, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Effects of Different Types of Carrageenan on the Prepared Soft Capsules

[0058] 1) chemical glue process

[0059] Weigh 8KG of different types of carrageenan, 30KG of hydroxypropyl starch, 15KG of glycerin and 47KG of purified water and place them in a chemical glue tank, heat to 80-90°C to swell the glue, keep it warm for 20-120min, and degas until the glue is clear translucent glue;

[0060] 2) Shot rolling process

[0061] Select 22 drops of cylindrical soft capsule mold, heat the rubber box of the pill rolling machine to 80-95°C, heat the drum to 20-40°C, supply glue, set the rubber thickness to 0.80mm, and machine speed to 1.5rpm to roll the pills. The content is linseed oil, then dried until the hardness of the capsules meets the requirements (50-70N), the pellets are selected, and finally packaged.

[0062] The seam rate, content loading, and oil leakage rate of soft capsules prepared from different types of carrageenan were tested, and the results are shown ...

Embodiment 2

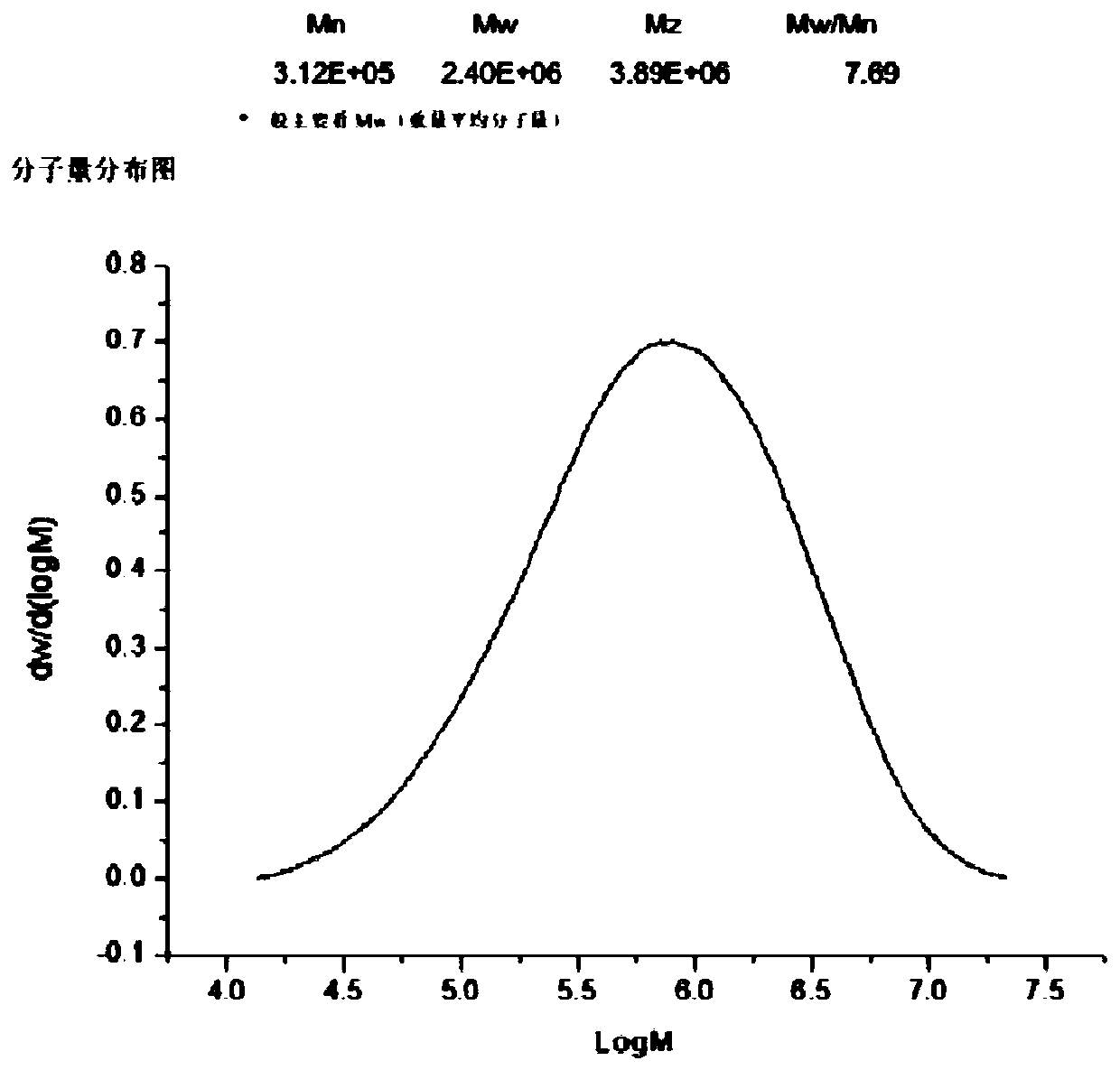

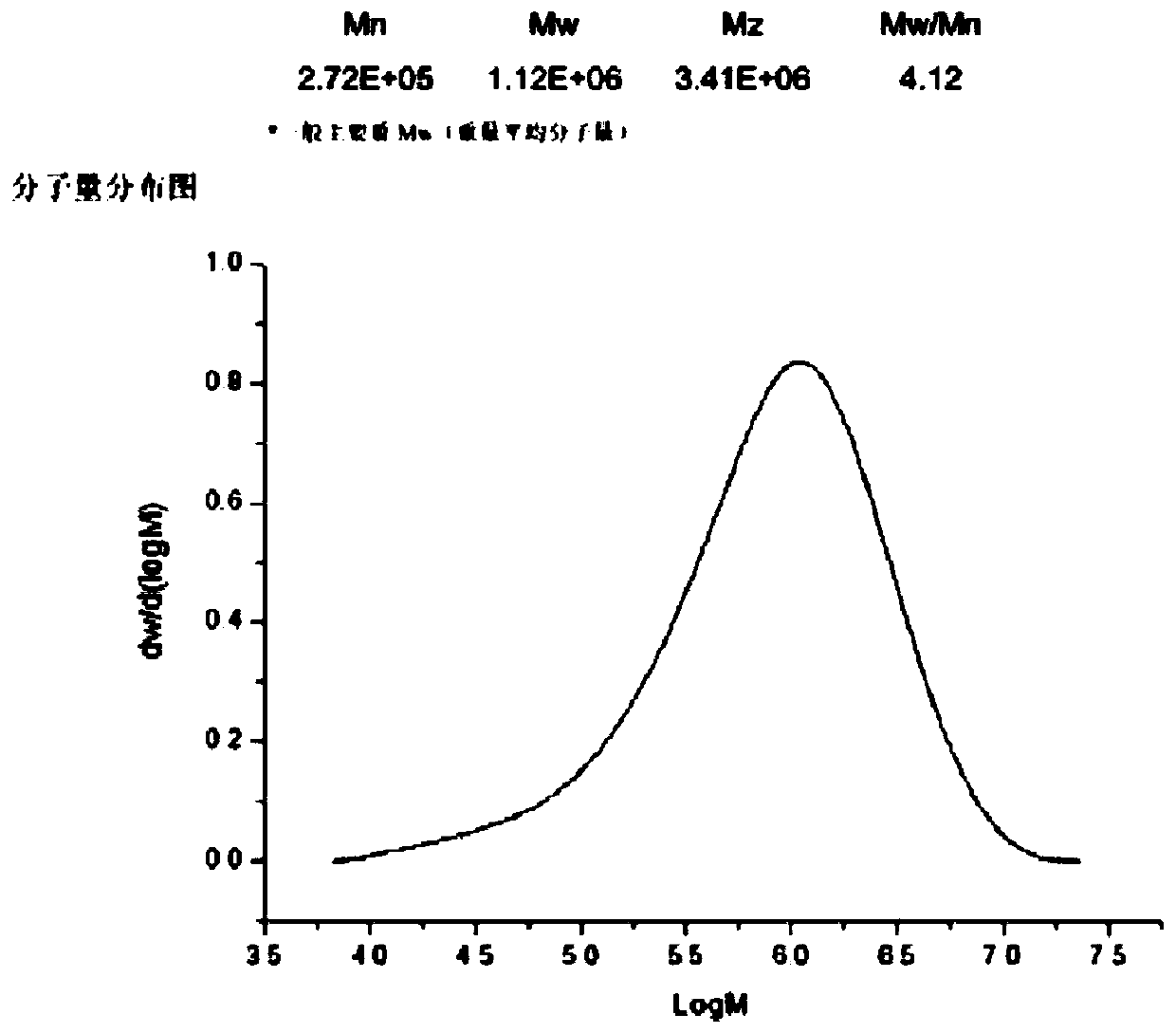

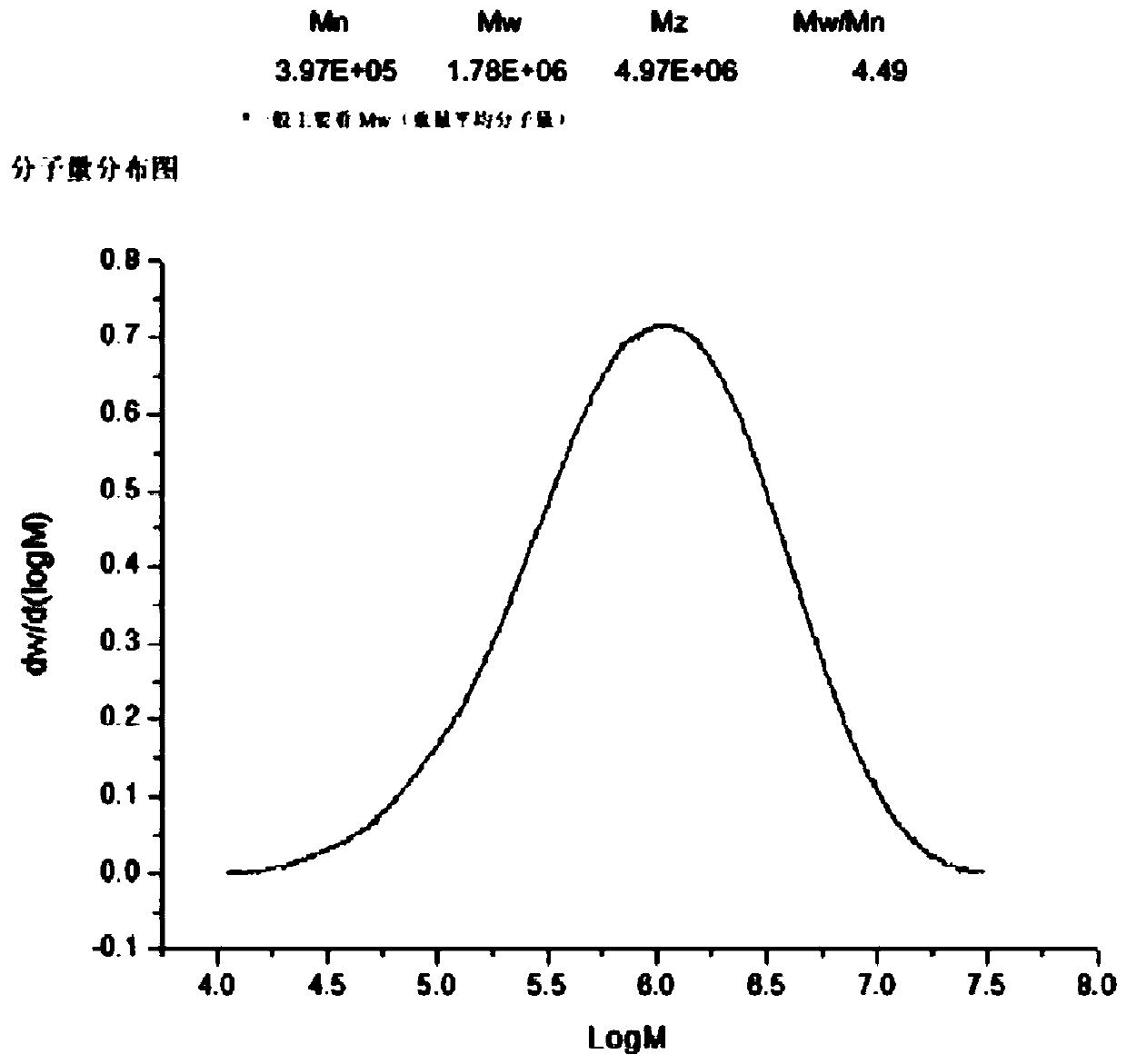

[0069] Effects of Carrageenan with Different Weight-average Molecular Weight on the Soft Capsules Prepared

[0070] 1) chemical glue process

[0071] Weigh 8KG of type I (Iota) carrageenan, 30KG of hydroxypropyl starch, 15KG of glycerin and 47KG of purified water with different weight-average molecular weights and place them in a chemical tank, heat to 80-90°C to swell the glue, and then keep it warm for 20-120min , degas until the glue is clear and translucent to get the glue;

[0072] 2) Shot rolling process

[0073] Select 22 drops of cylindrical soft capsule mold, heat the rubber box of the pill rolling machine to 80-95°C, heat the drum to 20-40°C, supply glue, set the rubber thickness to 0.80mm, and machine speed to 1.5rpm to roll the pills. The content is linseed oil, then dried until the hardness of the capsules meets the requirements (50-70N), the pellets are selected, and finally packaged.

[0074] The seam rate, content loading and oil leakage rate of soft capsule...

Embodiment 3

[0079] The impact of different drum temperatures on the properties of the prepared soft capsules:

[0080] 1) chemical glue process

[0081] Take by weighing 8KG type I (Iota) carrageenan (the weight average molecular weight of carrageenan is 1.50±0.1×10 6 ), 30KG hydroxypropyl starch, 15KG glycerin and 47KG purified water are placed in a glue tank, heated to 80-90°C to swell the glue, keep it warm for 20-120min, degas until the glue is clear and translucent to obtain glue;

[0082] 2) Shot rolling process

[0083] Select 22 drops of cylindrical soft capsule mold, heat the rubber box of the pill rolling machine to 80-95°C, heat the drum, supply glue, set the rubber thickness to 0.80mm, machine speed 1.5rpm to roll pills, and the content is flax Seed oil, then dried until the hardness of the capsules meets the requirements (50-70N), the pellets are selected, and finally packed.

[0084] The rubber seam ratio, content content and oil leakage rate of soft capsules prepared at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com