A kind of modified emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and modification, applied in building components, building insulation materials, construction, etc., can solve the problem that asphalt cannot meet the needs of use, and achieve excellent shear damage resistance, a wide range of raw material sources, and good weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

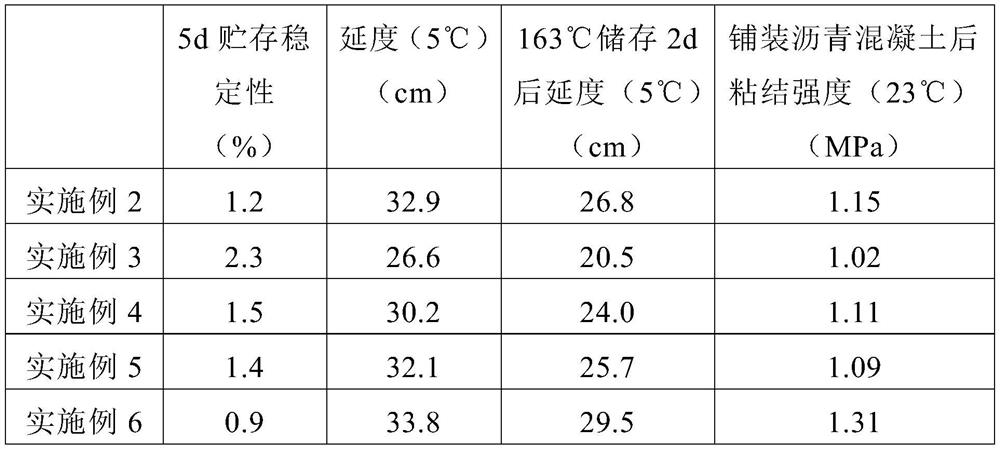

Examples

Embodiment 1

[0031] The preparation method of modified emulsified asphalt comprises the following steps:

[0032] (1) Heat 100 parts by weight of water to 80°C, then add 5 parts by weight of polyvinyl alcohol, 4 parts by weight of talcum powder, 4 parts by weight of ethanol, 1.6 parts by weight of cationic emulsifier, 0.04 parts by weight of tall oil, 0.8 parts by weight Parts by weight of polyacrylamide were stirred and mixed for 10 minutes at a speed of 300 r / min, and then 100 parts by weight of base asphalt and 5 parts by weight of thermoplastic styrene-butadiene rubber were added to heat up to 155°C and stirred and mixed for 20 minutes at a speed of 300 r / min to obtain a mixture;

[0033] (2) Shear and disperse the mixture at a speed of 1200r / min for 20 minutes to obtain modified emulsified asphalt.

[0034] The base asphalt is petroleum asphalt.

[0035] The cationic emulsifier is cetyltrimethylammonium chloride.

[0036] The polyacrylamide is nonionic polyacrylamide.

Embodiment 2

[0038] The preparation method of modified emulsified asphalt comprises the following steps:

[0039] (1) Heat 100 parts by weight of water to 80°C, then add 5 parts by weight of polyvinyl alcohol, 4 parts by weight of modified talcum powder, 4 parts by weight of ethanol, 1.02 parts by weight of antioxidant, and 1.6 parts by weight of cationic emulsifier , 0.04 parts by weight of tall oil, and 0.8 parts by weight of polyacrylamide were stirred and mixed for 10 minutes at a speed of 300r / min, and then 100 parts by weight of base asphalt and 5 parts by weight of thermoplastic styrene-butadiene rubber were heated to 155°C and stirred at a speed of 300r / min Mix for 20min to obtain the mixture;

[0040] (2) Shear and disperse the mixture at a speed of 1200r / min for 20 minutes to obtain modified emulsified asphalt.

[0041] The base asphalt is petroleum asphalt.

[0042] The cationic emulsifier is cetyltrimethylammonium chloride.

[0043] The antioxidant is p-cresol-dicyclopentadien...

Embodiment 3

[0047] The preparation method of modified emulsified asphalt comprises the following steps:

[0048] (1) Heat 100 parts by weight of water to 80°C, then add 5 parts by weight of polyvinyl alcohol, 4 parts by weight of talcum powder, 4 parts by weight of ethanol, 1.02 parts by weight of antioxidant, 1.6 parts by weight of cationic emulsifier, 0.04 parts by weight Stir and mix parts by weight of tall oil and 0.8 parts by weight of polyacrylamide at a speed of 300r / min for 10 minutes, then add 100 parts by weight of base asphalt and 5 parts by weight of thermoplastic styrene-butadiene rubber and heat up to 155°C and stir and mix for 20 minutes at a speed of 300r / min , to get the mixture;

[0049] (2) Shear and disperse the mixture at a speed of 1200r / min for 20 minutes to obtain modified emulsified asphalt.

[0050] The base asphalt is petroleum asphalt.

[0051] The cationic emulsifier is cetyltrimethylammonium chloride.

[0052] The antioxidant is p-cresol-dicyclopentadiene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com