Self-assembly antibacterial coating based on nano-silver/D-cysteine and preparing method

A cysteine and antibacterial coating technology, applied in coating, medical science, prosthesis and other directions, can solve the problems of silver poisoning and unclear mechanism of action, and achieve the effects of small side effects, easy preparation and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Sand the 316L stainless steel with a size of 10mm×10mm×3mm to 1500# with sandpaper, then ultrasonically clean it with acetone and alcohol in sequence and dry it in the air.

[0028] 2. Use Tris solution to prepare 2 mg / ml dopamine solution, and titrate the pH to 8.5. Put 316L stainless steel into the dopamine solution, and the solution submerges about 20mm above the top of the sample. Put the solution into a shaker, set the speed at 42rpm, and soak for 24h.

[0029] 3. Ultrasonic the sample taken out to remove the unstable dopamine particles attached to the surface, then put the sample in 5 mg / L silver nitrate solution, shield it with tin foil, and soak for 5 hours.

[0030] 4. Rinse the sample taken out with deionized water and put it in 10 -3 mg / ml D-cysteine solution, soak for 5 hours, take it out, rinse with deionized water, and dry naturally.

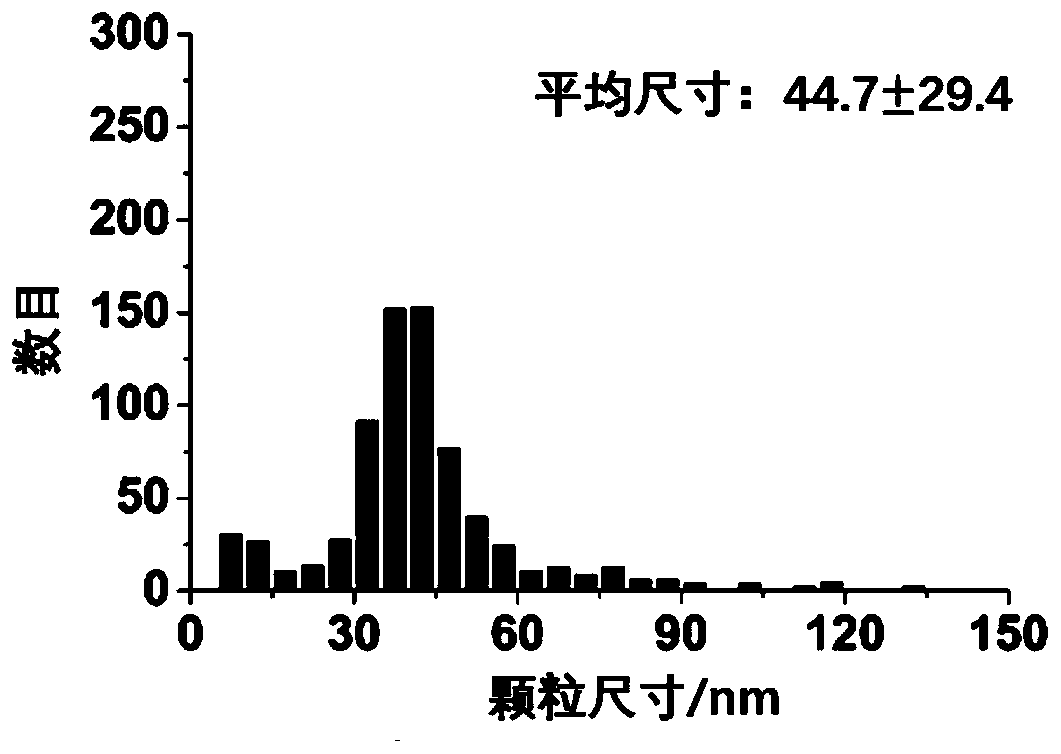

[0031] Figure 1a It is the scanning electron micrograph of the novel self-assembled antibacterial coating based o...

Embodiment 2

[0033] 1. Sand the base material titanium alloy with a size of 10mm×10mm×3mm to 1500# with sandpaper, then ultrasonically clean it with acetone and alcohol in sequence and dry it in the air.

[0034] 2. Use Tris solution to prepare 2 mg / ml dopamine solution, and titrate the pH to 8.5. Put the titanium alloy into the dopamine solution, and the solution submerges about 20mm from the top of the sample. Put the solution into a shaker, set the speed to 40rpm, and soak for 20h.

[0035] 3. Ultrasonic the sample taken out to remove the unstable dopamine particles attached to the surface, then put the sample into 1 mg / L silver nitrate solution, shield it with tin foil, and soak for 5 hours.

[0036] 4. Rinse the sample taken out with deionized water and put it in 5×10 -3 mg / ml D-cysteine solution, soak for 5 hours, take it out, rinse with deionized water, and dry naturally.

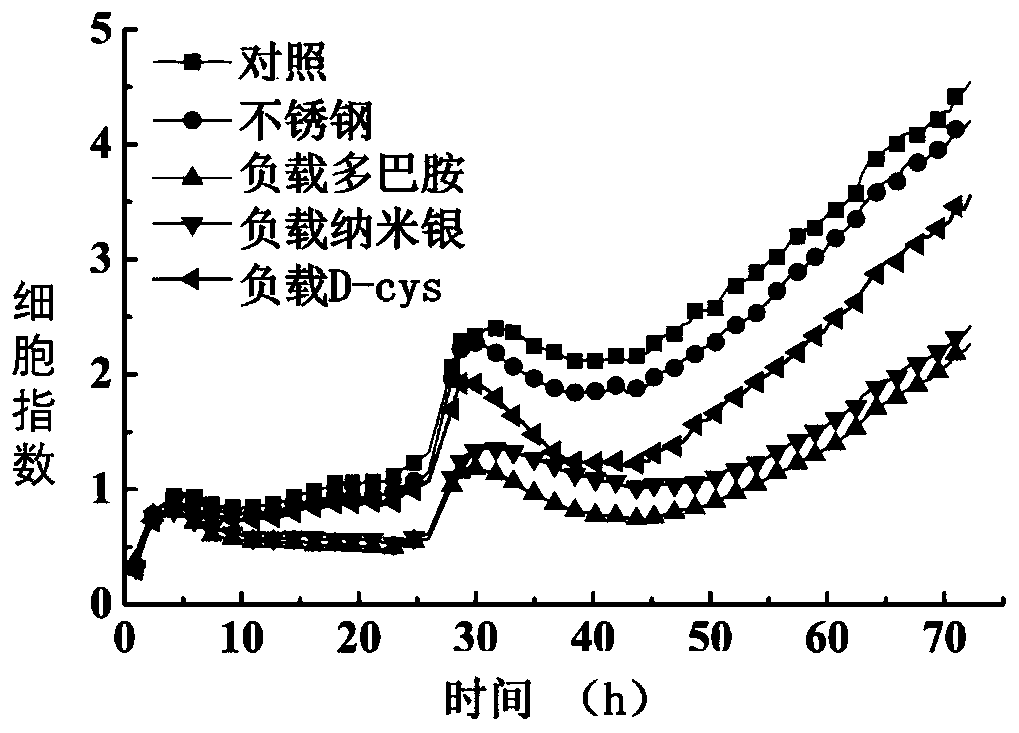

[0037] Fig. 3 is the antibacterial effect diagram of the novel self-assembled antibacterial coating based...

Embodiment 3

[0039] 1. Sand the base material magnesium alloy with a size of 10mm×10mm×3mm to 1500# with sandpaper, then ultrasonically clean it with acetone and alcohol in sequence and dry it in the air.

[0040]2. Use Tris solution to prepare 2 mg / ml dopamine solution, and titrate the pH to 8.5. Put the titanium alloy into the dopamine solution, and the solution submerges about 20mm from the top of the sample. Put the solution into a shaker, set the speed at 30rmp, and soak for 24h.

[0041] 3. Ultrasonic the sample taken out to remove the unstable dopamine particles attached to the surface, then put the sample in 3 mg / L silver nitrate solution, shield it with tin foil, and soak for 5 hours.

[0042] 4. Rinse the sample taken out with deionized water and put it in 10 -2 mg / ml D-cysteine solution, soak for 5 hours, take it out, rinse with deionized water, and dry naturally.

[0043] Fig. 4 is the antibacterial effect diagram of the self-assembled antibacterial coating based on nano-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com