A kind of solid composite electrolyte membrane and its preparation and application

A technology of composite electrolyte membrane and solid electrolyte, which is applied in the direction of solid electrolyte, electrolyte storage battery manufacturing, electrolyte, etc., can solve the problems of poor flexibility, narrow electrochemical window, and large interface impedance of inorganic solid electrolytes, and achieve low requirements for production equipment, The process is simple and the effect of blocking lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Another object of the present invention is to provide a method for preparing a solid composite electrolyte membrane, comprising the following steps:

[0036] Step 1, preparing an inorganic solid electrolyte by solid state reaction;

[0037] In step 1, the inorganic solid electrolyte consists of Li 1+x Al x Ti 2–x (PO 4 ) 3 Represents, wherein, 0

[0038] Inorganic solid electrolyte LATP is currently a common NASICON ceramic solid electrolyte. This solid electrolyte has excellent waterproof performance and lithium ion conductivity, and also has high mechanical strength.

[0039] Step 1 includes the following sub-steps:

[0040] Sub-step 1-1: weighing inorganic lithium salt, aluminum oxide, titanium oxide and phosphate according to the stoichiometric ratio, and mixing;

[0041] Substep 1-2: calcining the system obtained in substep 1;

[0042] Sub-step 1-3: pulverize the system obtained in sub-step 2, sinter, pulverize again, and dry in v...

Embodiment 1

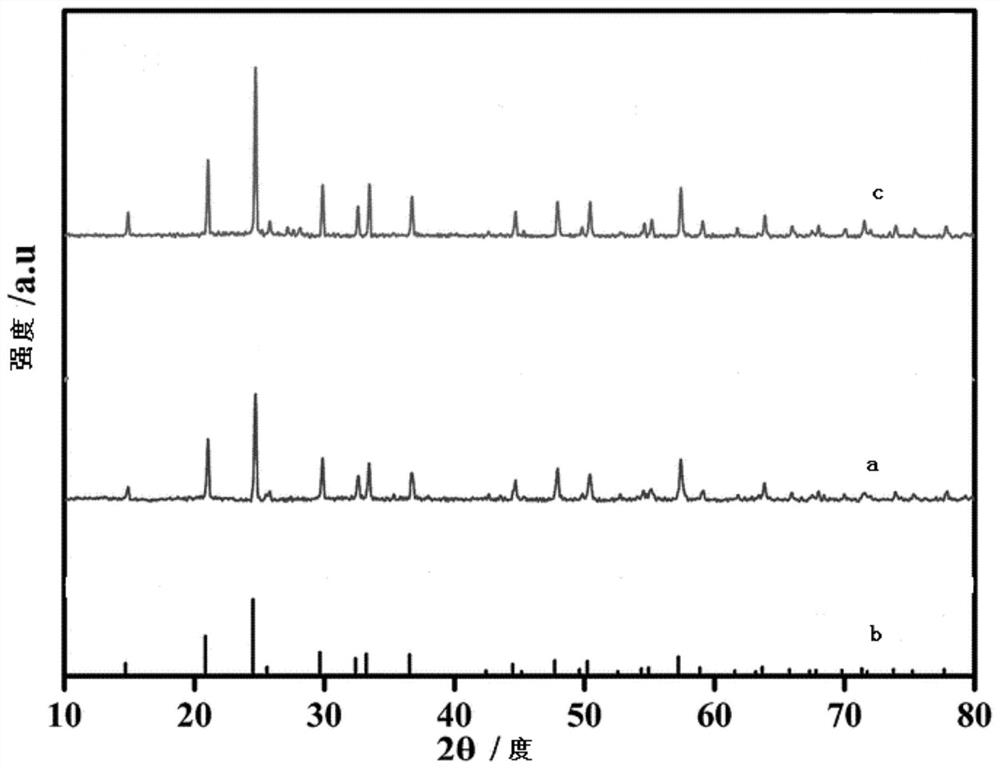

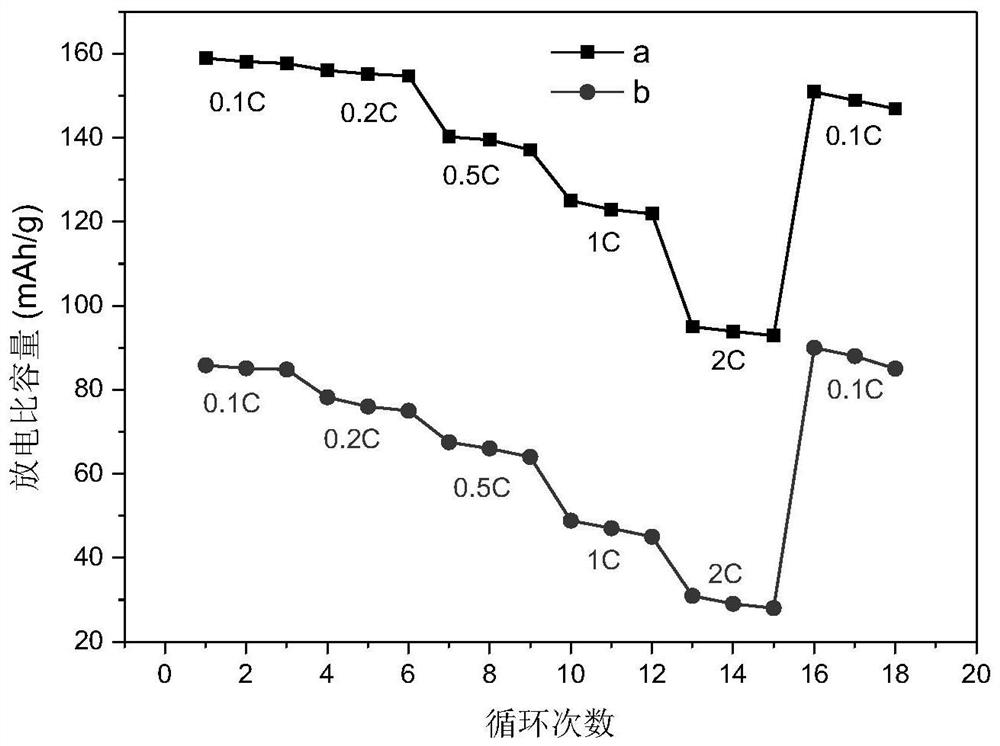

[0076] Weigh 0.0480g of lithium carbonate, 0.0153g of alumina, 0.136g of titanium dioxide and 0.396g of diammonium hydrogen phosphate according to the stoichiometric ratio, mix them uniformly, and sinter at 900°C for 2h. Ball milling with acetone as a solvent, followed by sintering at 900 °C for 2 h, ball milling for 6 h, and finally vacuum drying at 100 °C to obtain the inorganic solid electrolyte Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 , abbreviated as LATP-1;

[0077] Take 2.759g of tetrachloro-tere-phenylenedimethanol, add 20mL of anhydrous tetrahydrofuran to dissolve it, after the dissolution is complete, slowly drop 5mmol of 2M LiBH into the solution 4·THF solution, a white precipitate can be observed during the process, the reaction temperature is controlled at 45°C during the dropwise addition, after the dropwise addition is completed, stir and reflux for 6 hours, and the entire reaction process is carried out under the protection of an inert gas. After the reaction was co...

Embodiment 2

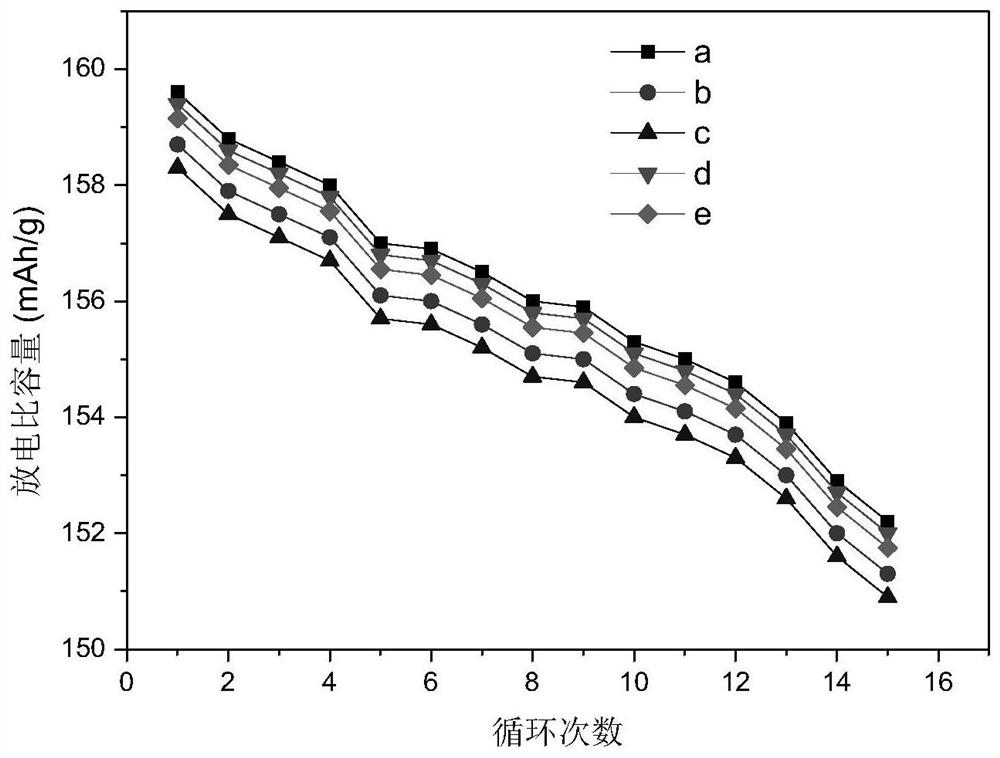

[0080] Weigh 0.0480g of lithium carbonate, 0.0153g of alumina, 0.136g of titanium dioxide and 0.396g of diammonium hydrogen phosphate according to the stoichiometric ratio, mix them uniformly, and sinter at 900°C for 2h. Ball milling with acetone as a solvent, followed by sintering at 900 °C for 2 h, ball milling for 6 h, and finally vacuum drying at 100 °C to obtain the inorganic solid electrolyte Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 , abbreviated as LATP-1;

[0081] Take 2.759g of tetrachloro-tere-phenylenedimethanol, add 20mL of anhydrous tetrahydrofuran to dissolve it, after the dissolution is complete, slowly drop 5mmol of 2M LiBH into the solution 4 ·THF solution, a white precipitate can be observed during the process, the reaction temperature is controlled at 45°C during the dropwise addition, after the dropwise addition is completed, stir and reflux for 6 hours, and the entire reaction process is carried out under the protection of an inert gas. After the reaction was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com