Three-dimensional metal lithium negative electrode and preparation method and application thereof

A lithium metal, three-dimensional technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of reducing the electronic conductivity of the main 3D framework, increasing the manufacturing cost and complexity, achieving high rate performance, and solving dendrites. Effects of lithium formation, long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

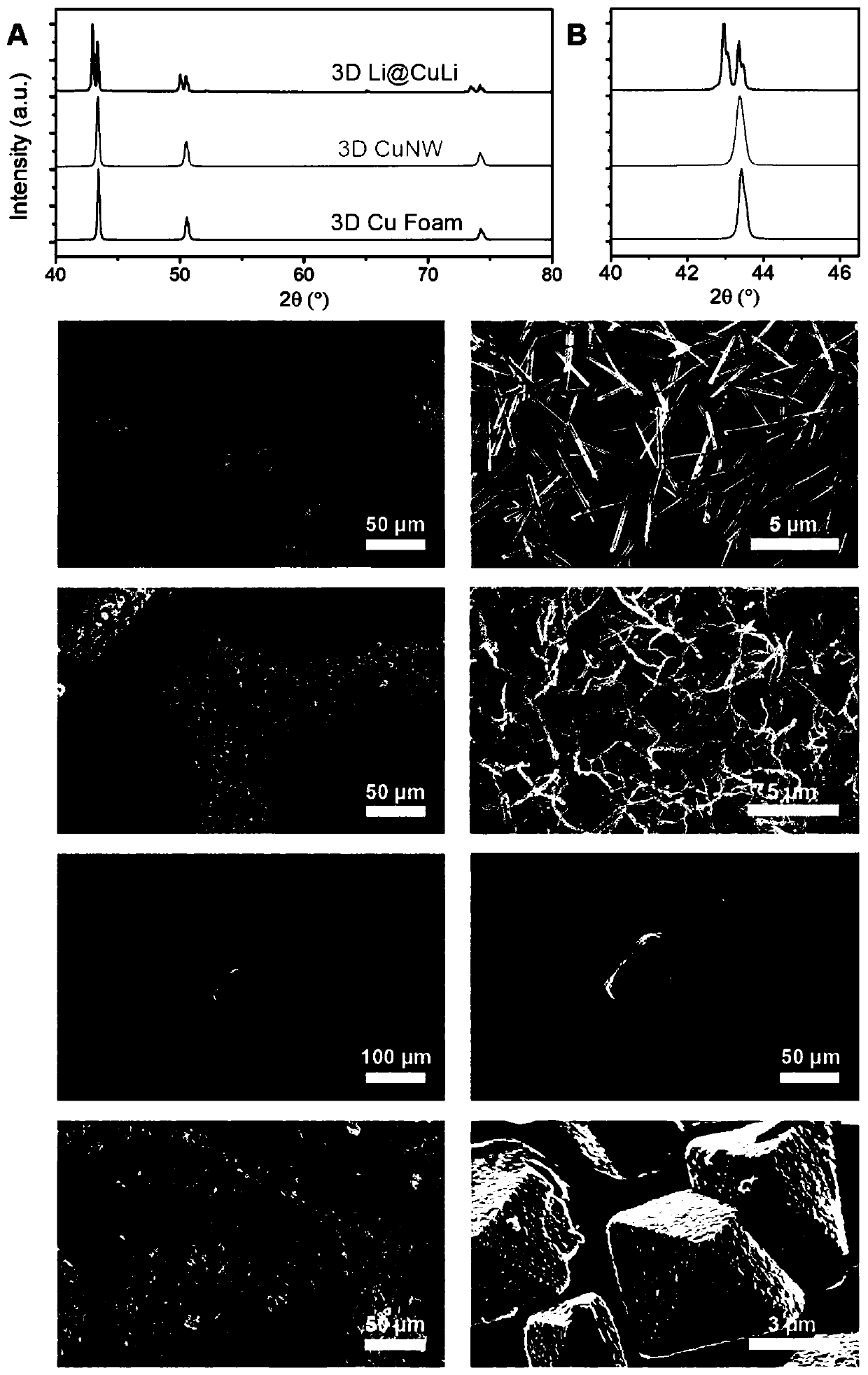

Embodiment 1

[0038] The three-dimensional copper foam was immersed in 2M NaOH solution and 0.1M (NH 4 ) 2 S 2 o 8 15 minutes in the mixture to form 3DCu(OH) 2 nanowire structure. After rinsing with deionized water and drying in a vacuum oven for 12 h, the 3D Cu(OH) 2 The foam is cut into discs. It was then placed in a tube furnace and heated to 180 °C under Ar flow for 2 h, then washed with 10% H 2 The airflow raised the temperature by 265 °C for 3.5 h. After allowing the tube furnace to cool down to room temperature, the resulting 3D CuNWs were quickly transferred into an argon-filled glove box. For the lithium infusion process, the Li foil was placed in a stainless steel vessel and heated to 350 °C. The 3D CuNWs are placed in contact with molten Li, where Li is injected into the structure to form the final 3D Li@CuLi electrode. Lithium melting process control time is less than 20 seconds.

Embodiment 2

[0040] Metal copper is sputtered on the three-dimensional copper foam by magnetron sputtering. The sputtering time is controlled to obtain nano-copper thin layers with different thicknesses. The Li foil was then placed in a stainless steel container and heated to 350 °C. The 3D Cu electrode is then placed in contact with the molten Li, where the Li is injected into the structure to form the final 3D Li@CuLi electrode. Lithium melting process control time is less than 20 seconds.

experiment example 1

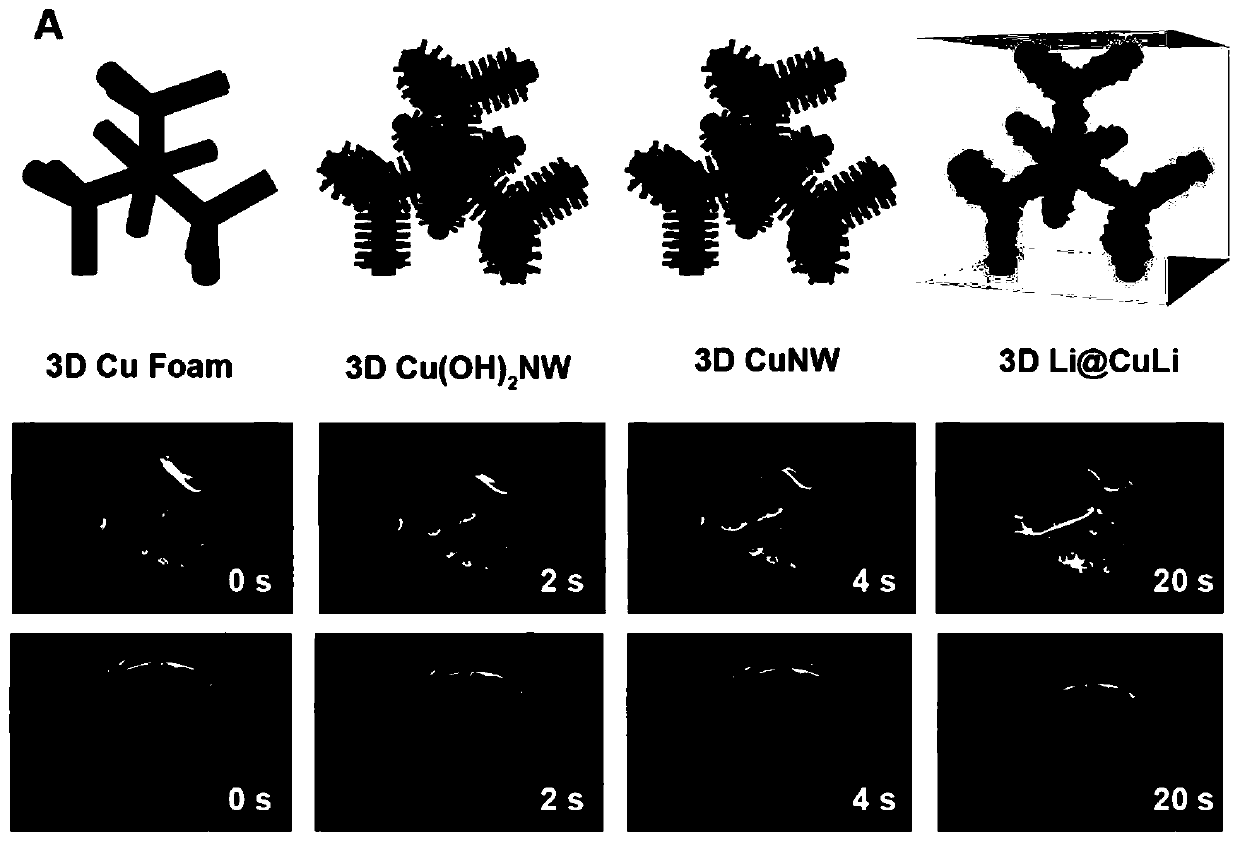

[0042] The schematic diagram of the three-dimensional framework structure modified by metal nanowires and the principle of melting lithium is shown in figure 1 A (different stages of electrode fabrication) is shown. figure 1 B is the injection of molten Li into 3D CuNW electrodes within 20 s. Inject molten Li directly into the three-dimensional copper foam without infiltration, see figure 1 c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com