Micro-nano lignocellulose, preparation method and applications thereof

A lignocellulose, micro-nano technology, applied in the fields of cellulose pulp post-treatment modification, fiber raw material treatment, textiles and papermaking, etc., can solve the problems of cumbersome and complicated preparation process, large environmental impact, cumbersome steps, etc., and achieve application Wide range, strong continuity, and the effect of weakening the hydrogen bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

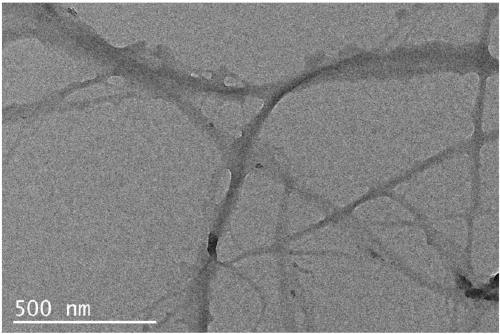

[0059] In this embodiment, the lignin content in the micronano lignocellulose is 22%, the cellulose diameter is 110 nm, and the aspect ratio is 212. The lignin is combined with the cellulose in the form of hydrogen bonds and chemical bonds.

[0060] Its preparation method specifically comprises the following steps:

[0061] (1) Take by weighing 10g xylose residue (wherein the lignin content in the xylose residue is 25wt%, the cellulose content is 70wt%, and the hemicellulose content is 5wt%) and is dissolved in 490mL 5mol / L urea aqueous solution, is heated to 72 °C and stir evenly to obtain a raw material dispersion of xylose residue;

[0062] (2) Place the xylose residue raw material dispersion liquid obtained in step (1) in a sand mill, and keep the temperature of the raw material dispersion liquid at 72° C. and circulate sand mill once to obtain a peeled object with a diameter of about 500 nm;

[0063] (3) Transfer the exfoliation prepared in step (2) to a high-pressure ho...

Embodiment 2

[0066] In this embodiment, the lignin content in the micronano lignocellulose is 25%, the cellulose diameter is 69nm, and the aspect ratio is 351. The lignin is combined with the cellulose in the form of hydrogen bonds and chemical bonds.

[0067] Its preparation method specifically comprises the following steps:

[0068] (1) Take by weighing 10g xylose residue (wherein the lignin content is 25wt% in the xylose residue, the cellulose content is 70wt%, and the hemicellulose content is 5wt%) and is dissolved in 490mL 10mol / L urea aqueous solution, is heated to 80 °C and stir evenly to obtain a raw material dispersion of xylose residue;

[0069] (2) Put the xylose residue raw material dispersion liquid obtained in step (1) in a sand mill, and keep the temperature of the raw material dispersion liquid at 80° C. and circulate sand mill once to obtain a stripped object with a diameter of about 500 nm;

[0070] (3) Transfer the exfoliated material prepared in step (2) to a high-pres...

Embodiment 3

[0072] In this embodiment, the lignin content in the micronano lignocellulose is 28%, the cellulose diameter is 88nm, and the aspect ratio is 298. The lignin is combined with the cellulose in the form of hydrogen bonds and chemical bonds.

[0073] Its preparation method specifically comprises the following steps:

[0074] (1) Weigh 10g of xylose residue (wherein the lignin content in the xylose residue is 28wt%, and the cellulose content is 72wt%), dissolve it in 490mL 5mol / L urea aqueous solution, heat to 80°C and stir evenly to obtain the xylose residue raw material dispersion;

[0075] (2) Place the xylose residue raw material dispersion liquid obtained in step (1) in a sand mill, and keep the temperature of the dispersion liquid at 80° C. and circulate sand mill once to obtain a stripped object with a diameter of about 400 nm;

[0076] (3) Transfer the exfoliation prepared in step (2) to a high-pressure homogenizer, and under the pressure of 60MPa, keep the solution tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com