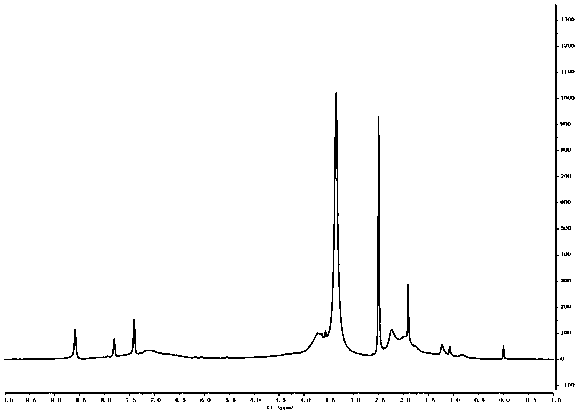

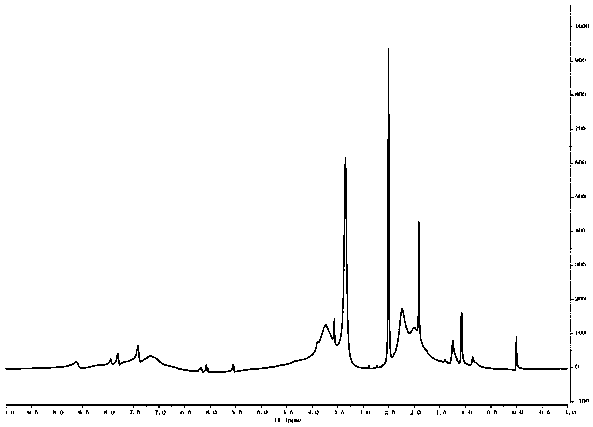

Modified acetic acid lignin polyurethane adhesive and preparation method thereof

A technology of polyurethane adhesive and lignin acetate, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problem of low lignin activity, achieve increased reactivity, less structural change, cheap to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

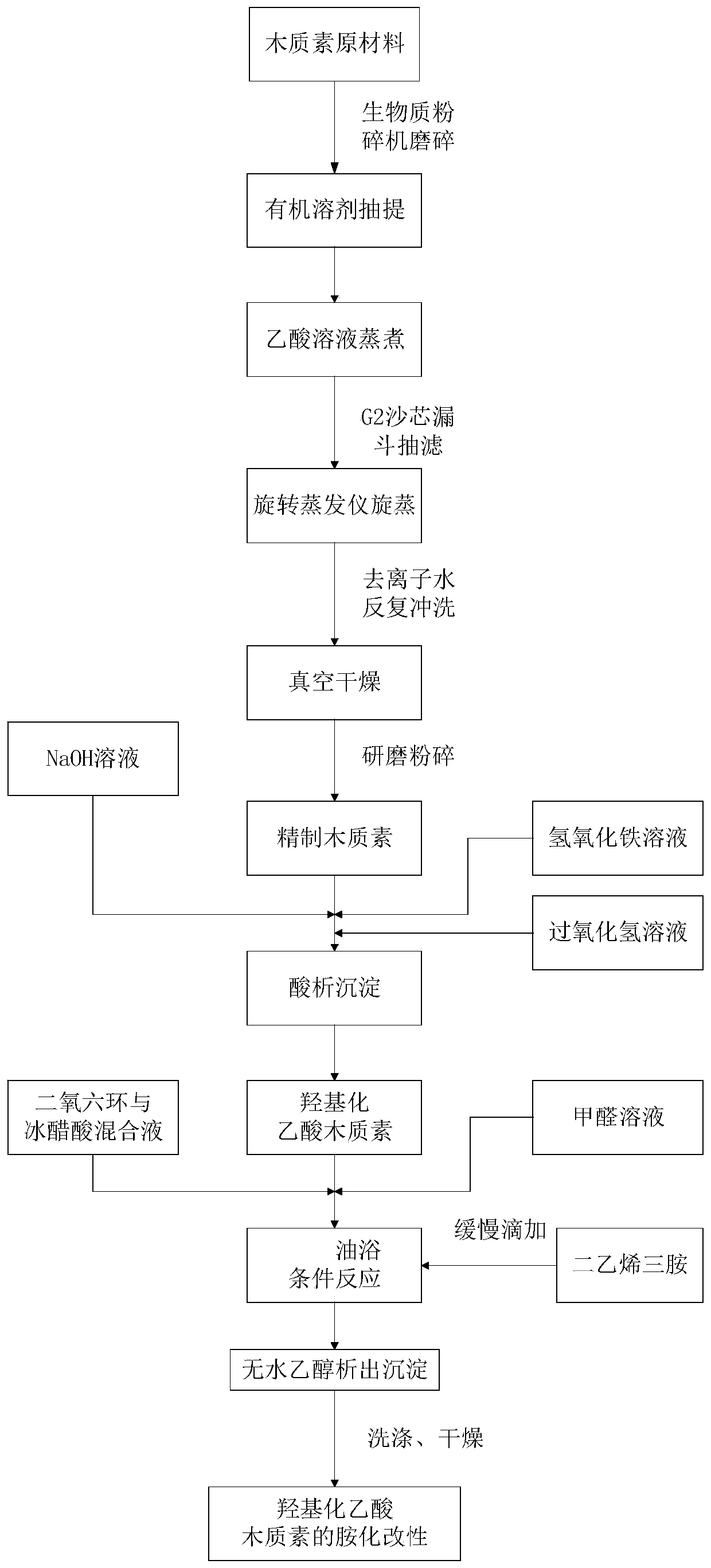

[0044] (1) Refining of acetic acid lignin: use 100ml of benzene-alcohol mixed solution (composed of benzene and ethanol with a volume ratio of 2:1) with 30g of ground and sieved eucalyptus lignin raw material in a water bath or oil bath Extract at 80°C for 8 hours; take out the biomass raw material, stir and dissolve it with 250ml of 95% acetic acid solution and cook it for 6 hours. block, filter to remove the residue; use G2 sand core funnel to filter to obtain the filtrate; add the filtrate dropwise to 2.5L of 70°C deionized water to fully disperse and precipitate the lignin; when separating the precipitate, use 70°C deionized water 200ml, wash repeatedly 5-6 times until the filtrate is translucent, light yellow and nearly colorless, and the pH is close to 7; put the separated precipitate in a vacuum drying oven at 40°C for 24 hours, put phosphorus pentoxide to absorb water; finally crush, pass through a 160-mesh sieve, Take the sieved sieve to obtain refined acetate lignin ...

Embodiment 2

[0049] (1) Refining of acetic acid lignin: 50g of ground and sieved eucalyptus lignin raw material is used in water bath or oil bath condition, using 200 mass parts of benzene-alcohol mixed solution (from benzene and ethanol with a volume ratio of 2:1 Composition) extract at 80°C for 8 hours; take out the biomass raw material, stir and dissolve it with 500ml of 95% acetic acid solution and cook for 6 hours; after cooking, filter with suction and concentrate the filtered black liquor until the black liquor becomes slightly viscous and No agglomeration, filter to remove the residue; filter with a G2 sand core funnel to obtain the filtrate; add the filtrate dropwise to 5L of 70°C deionized water to fully disperse and precipitate the lignin; when separating the precipitate, use a 70°C deionized Wash with 400ml of water for 5-6 times until the filtrate is translucent, light yellow and nearly colorless, and the pH is close to 7; put the separated precipitate in a vacuum oven at 40°C ...

Embodiment 3

[0054] (1) Refining of acetic acid lignin: 80g of ground and sieved eucalyptus lignin raw material is used in water bath or oil bath condition, using 250 mass parts of benzene alcohol mixed solution (by volume ratio is 2:1 benzene and ethanol Composition) extract at 80°C for 8 hours; take out the biomass raw material, use 1L of 95% acetic acid solution to stir and dissolve, and cook for 6 hours; after cooking, filter with suction, and concentrate the filtered black liquor until the black liquor becomes slightly viscous and No agglomeration, filter to remove the residue; filter with a G2 sand core funnel to obtain the filtrate; add the filtrate dropwise to 8L of 70°C deionized water to fully disperse and precipitate the lignin; when separating the precipitate, use a 70°C deionized Wash with 600ml of water for 5-6 times until the filtrate is translucent and light yellow and close to colorless, and the pH is close to 7; put the separated precipitate in a vacuum oven at 40°C for 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com