Modified lignin manufacturing method, modified lignin, and modified lignin-including resin composition material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

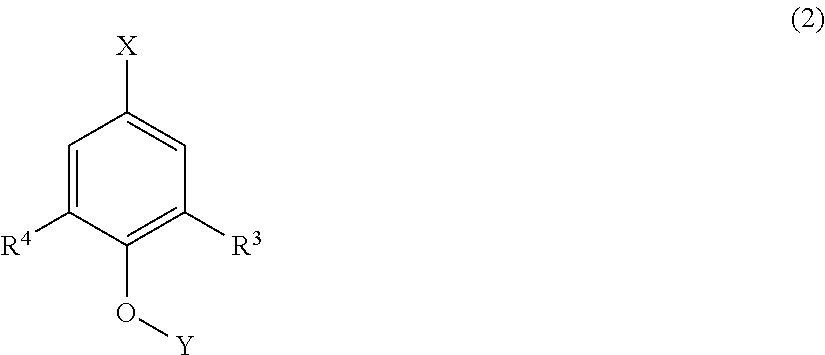

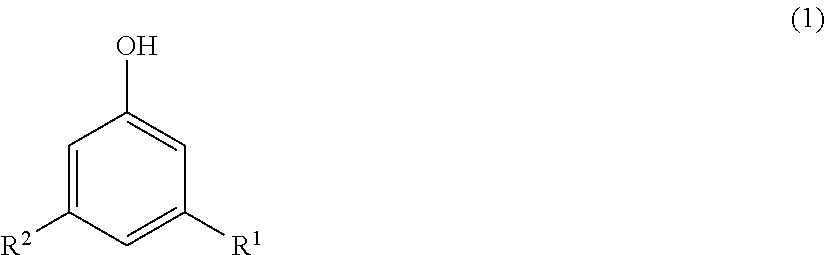

Method used

Image

Examples

example 1

(1) Reaction Process

[0139]29.5 parts by mass of a second generation ethanol saccharification residue (lignin content: 66% by mass) (29.5 g, 19.5 g of lignin), 180 parts by mass of phenol, and 1 part by mass of phosphoric acid were placed in a 1.0 L pressure tight vessel capable of performing agitation, and heated, and the agitation was started at the time when phenol was melted. The heating was continuously performed, and the content was heated to 200° C. for 4 hours.

(2) Purification Process

(2-1) Filtration

[0140]A 1.0 L hot pressure filtration device having set thereto No. 5C filter paper was fabricated and heated with warm water of 60 to 90° C. The total amount of the reaction liquid obtained in the reaction process was placed therein and filtered by pressurizing to 0.1 to 0.4 MPa with compressed air or nitrogen. The filtered solid was washed with phenol.

(2-2) Distillation

[0141]The filtrate obtained through the filtration was distilled by heating (100 to 130° C.) under reduced pres...

example 2

[0145]The same procedure as in Example 1 was performed except that 78 parts by mass of phenol was used, the acid catalyst was not used, and the reaction time was 2 hours, so as to provide a modified lignin 2 (amount of modified lignin: 17.7 g, yield: 91.4%).

example 3

[0146]The same procedure as in Example 2 was performed except that the reaction time was 4 hours, so as to provide a modified lignin 3 (amount of modified lignin: 18.9 g, yield: 97.2%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com